Effortlessly Scale Your Pre-Roll Production With Automation

Pre-rolls are where it’s at for operators seeking profitable opportunities in the burgeoning cannabis industry, as the product continues to become more popular amongst consumers. In fact, pre-rolls jumped from 13% to a record 15.9% of total cannabis sales between January 2023 and June 2024, underscoring their rapid growth and increasing market share.

However, the future success of these businesses depends largely on their pre-roll production efficiency. With the industry still heavily reliant on costly manual labor, operators struggle to scale while maintaining optimal profit margins.

Hence, the rise of automatic pre roll machine installations in facilities worldwide. So, if you’re looking to scale and haven’t implemented pre-roll automation yet, this guide is for you. Here, we’ll dive deep into the nuances of automation, including its impact on labor costs, consistency, and quality, and beyond.

Keep reading to learn more about automation from the leading pre-roll machine team at Hefestus.

Automation Reduces Labor Costs

With the rise of AI and increasing labor costs, operators across various industries are reviewing their systems and processes to seek opportunities for automation. The same applies to pre-roll production, considering that manually manufacturing pre-rolls, from filling to packaging, is a labor-intensive process.

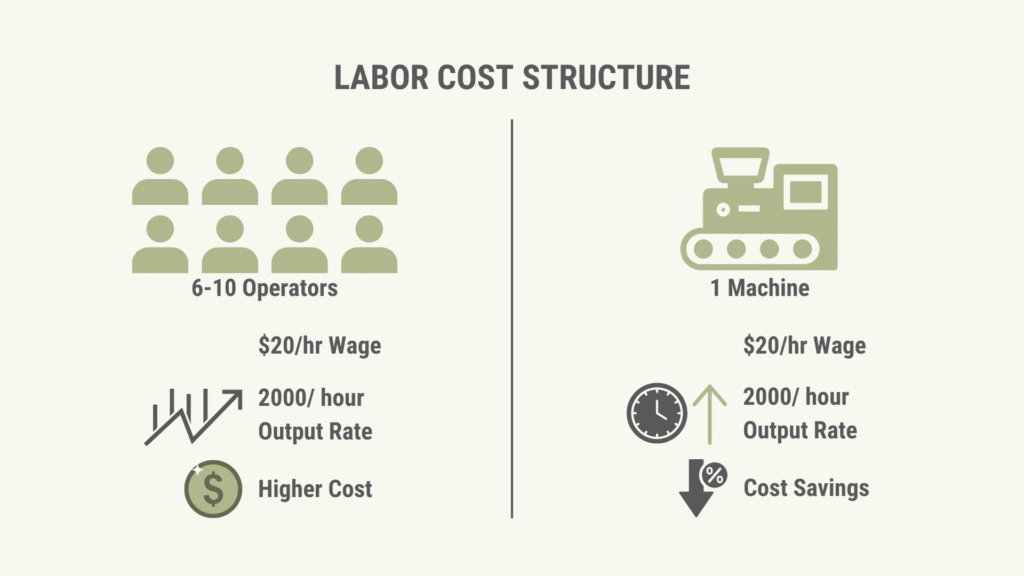

Typically, operations employ specific pre-roll production teams that work 8-hour shifts at hourly rates ranging from $13 to $16, depending on the region. The filling team typically consists of 3-5 employees, as does the cannabis pre-roll packaging team, totaling 6-10 employees. Beyond, there could be additional workers employed for quality control, compliance, or inventory support.

Doing the math in your head… It’s clear why operators turn to fully automated pre-roll machines to scale, as labor costs can quickly become a burden to the overall bottom line. In comparison, pre-roll automation reduces the need for large labor teams, which in turn allows workers to seek more fulfilling positions.

Smaller teams result in significantly reduced payroll expenses, enabling improved profit margins. This is demonstrated by real-time case studies across the industry, such as operations that implement the Hefestus AuraX automated pre-roll machine. The AuraX model has proven to boost production efficiency, replacing up to 16 manual operators and reaching output rates of 2,000 pre-rolls per hour.

Ensuring Consistency and Quality Across Every Pre-Roll

When it comes to pre-roll consumers, the margin for error in retaining returning customers can be slim. In a sea of competitors, if a consumer tries your brand and experiences any common issues like underfilling, too tight of filling, uneven burn, or beyond…it’s likely it’ll be their last.

Overall, in the cannabis industry, consistency and quality are two key factors that establish consumer trust and foster brand loyalty. Of course, filling, packing, and twisting pre-rolls day in and day out can be a mindless and tedious job. Meaning, it’s inevitable that human errors will lead to inconsistencies, thereby affecting consumer loyalty.

When removing humans from the operation, you’ll not only free up your labor force to take on more inspiring tasks, but you’ll also speed up the process and ensure consistency in key consumer traits, such as size, weight, and fill. Advanced automation equipment, whether pre-roll machines or cannabis pre-roll packaging automation tools, provides precise control over every element of production.

When doing so, you’ll also reduce the likelihood of flawed or underperforming products reaching consumers. This type of consistency translates into significant sales and business benefits nearly immediately.

Brands that maintain higher standards often see:

- Fewer customer complaints

- Fewer product returns

- Improved online reputation

- Less raw material waste due to improperly filled or damaged cones

In an industry where margins are tight and customer retention is crucial, automation doesn’t just help save time and money. It protects your brand’s reputation and ultimately enhances profitability in the process.

Speed Up Production to Meet Growing Demand

As demand grows, so must supply and your operations’ ability to produce it cost-effectively and efficiently.

To continue learning about the current state of the pre-roll market, here are a few stats to consider when considering investing in your operation to scale:

- Pre-roll popularity: As we shared earlier, pre-rolls now make up nearly 16% of total cannabis sales, up from just 13% in early 2023, making them one of the fastest-growing product segments in the industry. This boost in sales reflects higher consumer demand and aligns with an overall shift in consumer preferences towards convenience and ready-to-use products, similar to that seen with disposable vapes.

- Premium varieties: Another rapidly growing product category is infused pre-rolls and multi-packs. These products enable operators to differentiate their SKUs with premium sales, considering infused varieties capturing over 44% of pre-roll revenue in major U.S. markets. These high-margin products appeal to connoisseurs and new users alike, but require consistency and precision in production to maintain quality at scale.

- Pricing: Retail prices for pre-rolls are lower than those of other products, intensifying the need for efficient production systems that can preserve margins. Brands relying on manual labor often struggle to meet volume needs profitably, especially when competing on both price and quality.

- Projections: Market projections indicate that pre-rolls will surpass $4 billion globally by 2025, with sustained double-digit growth projected through 2030. To capitalize on this demand, brands need scalable, automated solutions that increase output without sacrificing consistency or compliance

All in all, pre-rolls are the third most popular product category, and there is no indication that popularity or demand will decrease anytime soon. For new or existing operators, implementing automation helps increase the speed of overall production, allowing them to provide the supply to meet existing demand while also maintaining consistent quality.

Scale Pre-Roll Production with Flexibility and Ease

In an ever-evolving industry like cannabis, it’s also crucial to have the capability of scaling production with flexibility and ease. That means the pre-roll automation tools you invest in for your business should have the ability to easily scale up or down, adjusting production volumes in response to market demand.

Automation systems designed for pre-roll manufacturing, like those from Hefestus, offer cannabis businesses the ability to scale production up or down seamlessly. For instance, the AuraX offers versatility that supports a variety of pre-roll types, allowing brands to more easily expand SKUs and product collections, from various sizes to paper types.

Hefestus can even support your operation from grind to fill, with its low heat industrial grinder and beyond, with flower packaging, and more. When looking for pre-roll automation tools, it not only helps to partner with a brand that can grow alongside your brand, but also to seek out specific features that’ll support flexible scaling with ease, including:

- Modular designs: Easily expand or reconfigure systems as your business grows.

- Batch versatility: Seamlessly switch between limited-edition runs and full-scale production without incurring extensive downtime.

- Precision across volume: Maintain consistent quality, regardless of batch size.

- Minimal operator dependency: Fewer operators are required to manage even the highest output, enabling lean and efficient teams.

Equipping your operation with adaptability ensures your business is never overcommitted or underprepared. Hefestus provides automation systems that scale with you, allowing you to respond more quickly and seamlessly to market trends, seasonal shifts, and emerging consumer demands without sacrificing quality or efficiency.

Streamlining Operations for Increased Efficiency

It’s a standard business practice to streamline operations to increase efficiency to improve profits. In cannabis, that practice is no different. For brands seeking to scale with new SKUs, expand operations, or enter new state markets, pre-roll automation will be crucial to their overall success.

Investing in automation doesn’t just improve efficiency—it simplifies the complex. With manual workflows, scaling production often requires expanding labor, workspace, and oversight. But with fully automated systems, operators can consolidate operations while increasing output.

Automation allows you to eliminate redundant processes, minimize waste, and dramatically reduce downtime between batches or SKUs.

This is especially vital for cannabis businesses seeking to introduce new pre-roll types or expand into multiple state markets without compromising turnaround time or consistency. As markets evolve and consumer expectations rise, streamlined operations help your business remain agile, lean, and primed for growth.

How Hefestus-Tech’s Automated Systems Can Help Cannabis Businesses

The more you know, the better you can scale. Now that you understand how pre-roll automation boosts production and protects your bottom line, there’s no reason to hold your operation back. The time is now to install a fully automated pre-roll machine to gain a competitive edge, improve profit margins, and spur growth.

It’s not just efficiency that pre-roll automation supports, but also product quality, consistency, and compliance. The versatile equipment enables operators to achieve high-quality standards, overall enhancing customer satisfaction and loyalty, and ultimately leading to increased sales.

Simply put, automation is crucial for cannabis businesses aiming to remain competitive, scale efficiently, and comply with regulatory requirements. However, not all fully automated pre-roll machines can be treated equally. They can vary significantly in terms of efficacy, efficiency, capabilities, and the availability of equipment repairs and support (see our best automated joint rolling machine breakdown for more).

Stay ahead with Hefestus, a leading manufacturer of advanced cannabis automation equipment. Contact Hefestus-Tech for a consultation or demo of pre-roll automation systems to boost production efficiency.