How To Choose The Right Automated Packaging System For Your Scale

For cannabis operators, it’s not only about learning how to operate within a new and ever-evolving industry…it’s about learning how to do so, competitively, to scale. With an ever-growing market of brands, today, consumers can be more selective than ever. Add on ever-increasing labor costs, and the two together demand outputting a quality product, at a favorable profit margin, to even consider scaling.

That’s where automated packaging systems come into the conversation. But not just any automated packaging solution, it’s got to be scalable automation that actually works, to avoid wasting time, money, and efforts on a workflow that just doesn’t work. Now, that’s where this ultimate guide comes into play.

Here, we’ll dive deep into the ins and outs of what to consider for selecting business automation solutions, from start to purchase. Continue reading to discover why choosing the right system is crucial, where to start your search, the various types of systems to consider, and ultimately, how to make an informed choice.

Why Choosing The Right System Matters

First and foremost, the best pre roll automation systems are an investment, which emphasizes the importance of selecting the right one that works effectively. Investing in automation is more than just speeding up your production line; it’s the foundation for sustainable growth, which requires more than just the best-priced model available that gets the job done.

What can happen when selecting the wrong solution? Production delays, downtime due to repairs, and numerous calls to the support team. On the other hand, choosing the right equipment can provide steady output, lower labor costs (almost immediately), seamless compliance, and, most importantly, consistent product quality every run.

In today’s tight-margin cannabis market, quality and efficiency are non-negotiable. When kicking off the search for the right system for your unique operation, ask yourself this: Will this system support both my current needs and my future growth?

Define Your Scale, Because One Size Doesn’t Fit All

Of course, during your search, nearly every piece of equipment will describe itself as “scalable”. However, the goal to scale for one operation can vary significantly from another. For instance, a boutique craft line producing 5,000 joints per week has very different requirements than a multi-state operator shipping hundreds of thousands. Which means, you’ll need to define precisely what scale means to you and your facility.

Is the goal to run additional SKUs? Are you preparing to expand into new markets? Start by mapping out your current daily output, the number of SKUs already in rotation, and how often you’ll need to make equipment changes or formatting swaps. Once you know more about what scaling means to you, you can shop for systems that actually match your goals instead of chasing ill-fitting features.

Types Of Automated Packaging Systems (And Who They’re For)

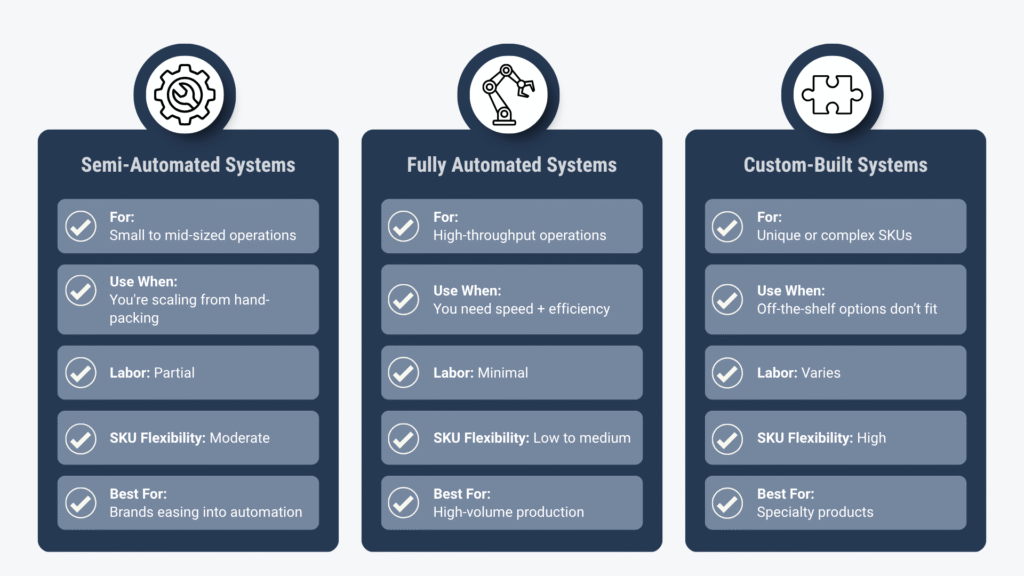

Simply put, different operators need different automated packaging systems. Your choice should reflect your product, volume, and the speed at which you’d like to achieve. Again, to help you narrow down the options available today, below is a breakdown of the most commonly implemented cannabis business automation solutions.

- Semi-Automated Systems: Semi-automated systems are precisely that; they automate certain parts of the workflow but rely on human labor for other parts. They’re best for growing brands that want more consistency without fully committing to automation, or for those transitioning away from hand-packing while keeping labor manageable.

- Fully Automated Systems: Fully automated systems are designed to automate every step of the process for producing a single product. They handle everything from filling to sealing, labeling, and sometimes even weighing, all in one streamlined workflow, making them ideal for high-throughput environments.

- Custom-Built Systems: If your product line doesn’t fit into traditional categories, such as infused speciality pre-rolls, edibles, or anything extraordinary or unique, a custom build may be the right way to tackle your unique SKU or operational flows.

Another important distinction to consider when searching for scalable automation that works for your operation is whether the equipment is modular and configurable as well. Available for both semi-automated and fully automated systems, this feature enables the equipment to adapt to varying SKUs by swapping out components, allowing for quick format changes without major downtime.

How To Choose Based On Throughput, Product Type, And Flexibility

The next step in the process for selecting an end-of-line packaging automation system is to identify your needs in three key areas: throughput, product type, and flexibility. When doing so, you can specifically search out the features that’ll support your unique operation, and remove the ones from the list that don’t.

- Throughput: How many units do you need to package per shift or day? Choose a system that can match your pace without slowing your line down.

- Product Type: Whether you’re working with flower, pre-rolls, or edibles, look for systems specifically designed for those formats. Specialized features like weight sensors, nitrogen sealing, or adjustable fill parameters matter here.

- Flexibility: Can you switch between hardware styles easily? Can the system handle SKU changes without hours of reprogramming? Flexibility protects your production line from bottlenecks and lets you adapt faster when demand shifts.

Again, try to think beyond the present and be future-minded in your thinking. Consider what your operation may need in 6 to 12 months, when your business will look different.

Cost Vs. ROI: What To Expect By Scale

Last but not least, and as we’ve previously mentioned, automation isn’t cheap. Luckily, the ROI can add context to the costs you’re considering. For smaller operators, semi-automation can reduce labor while preserving quality, often hitting ROI in under 12 months. For larger facilities, fully automated systems can reduce labor costs by over 50% and scale production 3–5x, with ROI in as little as 6 months.

Ultimately, don’t just compare price tags. You’ll want to consider and compare the time and labor costs saved, the output gained, and the stresses you’ve avoided (including compliance risks). In the end, a $100K machine that saves you $300K/year is a wiser move than a $40K one that breaks down and requires service every week.

What’s Your Scale, And What’s Your Next Move?

With this guide, you’ve learned why choosing the right system matters, and all of the factors to consider when selecting what’s just right for your operation. Now, the only thing to decide is which automated packaging system manufacturer you can rely on for reliable, consistent, and scalable automation.

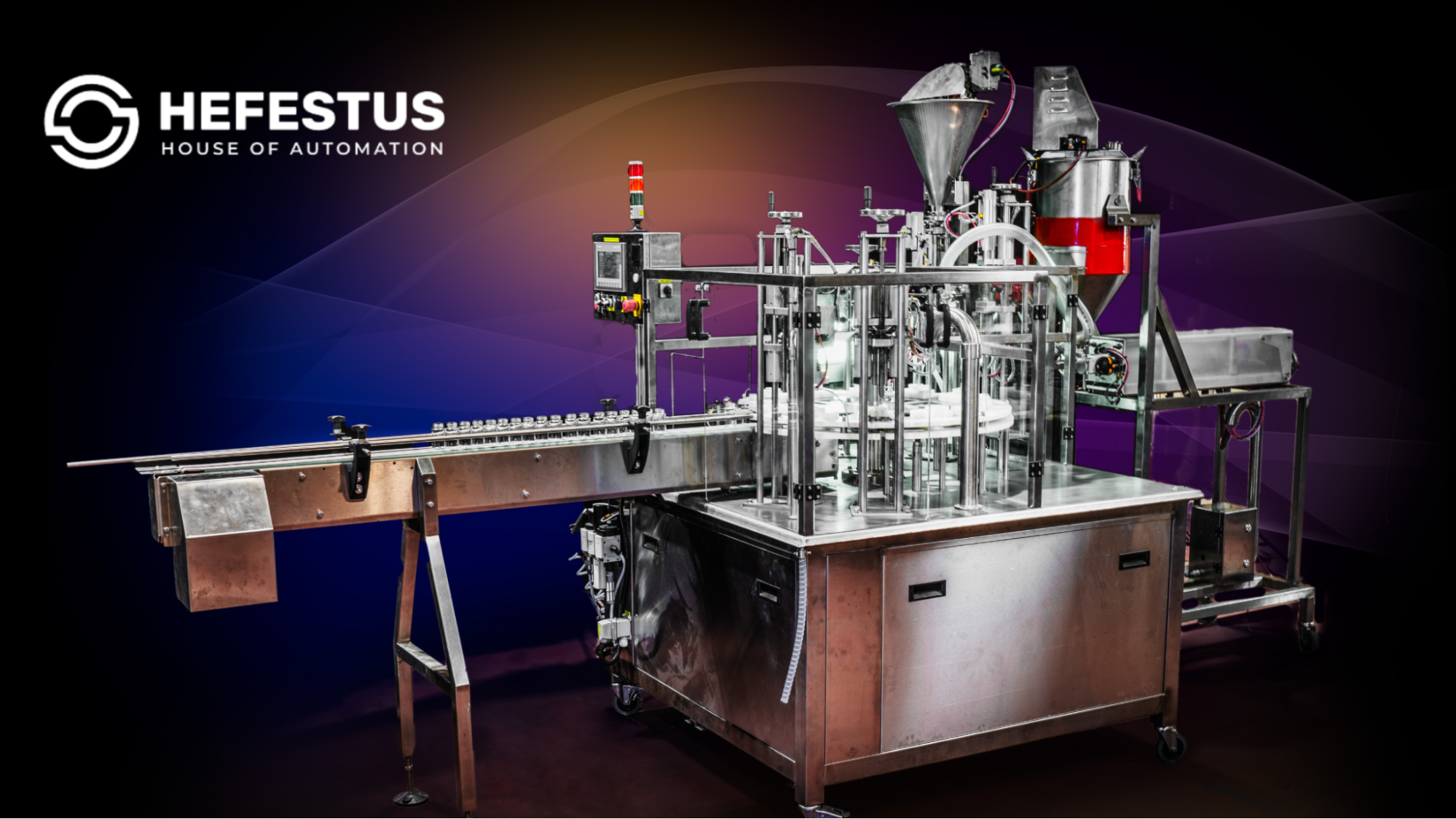

Get to know Hefestus, the original innovator of automated packaging solutions, including the AuraX, our flagship cannabis pre-roll machine, designed specifically with the unique operations of this industry in mind. From consistent product quality to consumer retention, precision weight tools for compliance, seamless automated workflows for optimal efficiency, and beyond, we’re proud to offer the cannabis industry the best systems for industrial automation.

We’re not called the House of Automation for nothing. Explore our cannabis business automation solutions today to build a scalable future for tomorrow.