Grinding Flower For Optimal Consistency With A Commercial Cannabis Grinder

For both consumption and production, the grind of the flower is essential, yet often overlooked. But because it can affect how a pre-roll smokes (in flavor and smoothness!) for the consumer, it’s crucial to get it right, especially in such a competitive market. Today, consumers have a plethora of options to choose from, and an increasing demand for a quality experience.

That means operators are now looking at the effectiveness of their commercial cannabis grinders more than ever before.

Of course, grinding weed just right isn’t just for product quality and consistency; it can affect precision, product waste or loss, and overall efficiency, too. So, if you’re not already equipped with the best grinder for weed…it’s time to start exploring options now. Luckily, you’re in the right place. Here, we’ll break down all the basics of how to grind bud right, to meet the high-quality standards consumers demand.

Grinding Flower Matters, A Lot More Than You Think

While most operations focus on the actual cultivation techniques of growing its flower, or sourcing the hottest strains, it’s the grinding of the flower that lends to consistent quality pre-roll experiences. So, to keep your SKUs on the top shelf and to help retain customers, it’s wise for facilities seeking a competitive advantage to learn more about how to grind cannabis properly.

Simply put, poor flower grinder results can compromise everything downstream. From uneven burning to less flavorful experiences to filling pre-rolls evenly for compliance and customer standards, dialing in just the right particle size is an art form that demands consistency.

That’s where industrial cannabis grinders enter the conversation. With advanced commercial cannabis grinders (like Hefestus’ TerpPreserve), the task evolves from a manual chore (with increased risk of human errors!) into a controlled, repeatable process that safeguards quality at scale.

Why Consistency Is Everything

Before exploring how to choose the right commercial grinder, let’s first elaborate on why consistency is everything in today’s cannabis industry. First and foremost, an even particle size is the number one must-have for an even burn with predictable potency, especially for premium and infused pre-rolls.

Without a consistent particle size, consumers are at risk of experiencing:

- Canoeing: When the flower grinder outputs various-sized particles, a pre-roll can “canoe,” the term for when one side of the pre-roll burns faster than the other.

- Improper airflow: Another annoyance improper grinding can cause for consumers is an improper airflow, where the flower packing is too tight and stiff to draw, or too loose and burns too quickly.

- Flavor loss: An even grind provides an even surface area for burning, allowing the terpenes and cannabinoids to volatilize steadily. An overly fine grind can also lead to a harshened flavor from burning too fast. On the other hand, too coarse of a grind can leave flavor behind because it does not completely combust.

All of the above can affect a brand’s ability to retain customers, making it that much more critical to implement processes for grinding weed properly.

Choose The Right Commercial Grinder

There are a few common challenges that arise with manual grinding, or lower-quality industrial cannabis grinders, including heat buildup, terpene loss, irregular particle sizes, and inefficient labor or workflows. So, the key to choosing the right commercial cannabis grinder is to select one that addresses all of the above.

From there, you’ll need to decipher between models and manufacturers, where you’ll want to consider a few key factors for your unique operation. Not only in its current standing, but to reach its desired goals, too. When selecting the right commercial cannabis grinder for your operation, here are three critical factors to consider:

- Capacity: Are you a boutique or specialty brand, with a low throughput? Or a large wholesale provider in demand for high-capacity outputs? Consider the capacity of the grinders you’re exploring to decide which will process large volumes effectively and efficiently.

- Speed: Even though a faster speed can increase throughput, it can also add to excess heat and friction inside the equipment, which will lead to degradation of terpenes. These two factors can degrade cannabinoids and terpenes, affecting overall quantity, so the speed in which you desire or demand should keep this in mind.

- Output Size: While we’ll touch on differing product types later in this guide, it’s important to know that adjustable grind settings are essential for tailoring particle size. This is essential to producing different pre-roll SKUs (e.g., standard vs. infused), and ensuring precision and consistency across product lines.

Finally, you’ll also want to consider the type of grinding mechanism. While blade grinders chop material quickly, they create inconsistent particle sizes and excess heat, leading to terpene loss and poor pre-roll performance.

On the other hand, mill or grind plate systems, like the TerpPreserve Grinder from Hefestus, use precision-engineered plates to shear flower material evenly. This mechanism preserves the flower’s natural profiles, preserving its integrity, while delivering a uniform, repeatable output ideal for automated pre-roll filling.

How To Prep Your Flower For Grinding

Another step in the process that significantly affects flower grinder results and overall product quality is proper curing and drying of the flower. For the best particle size and texture, it’s best to begin with flower material that has been cured and dried to just the proper moisture level. If the flower is too dry, it’ll turn to dust; if it’s too wet, it’ll clump in groups.

The removal of stems and seeds is also crucial to prevent damage to your pre-roll grinder and to achieve a smoother, more uniform grind. For best results, break down oversized buds manually to improve efficiency and avoid uneven particle sizes.

Lastly, the storage of the flower before grinding can also affect its results. Always be sure to keep material in airtight, temperature-controlled containers to preserve potency and terpene content. While grinders like the TerpPreserve handle large volumes efficiently, proper prep ensures you get the most out of every run while maintaining product integrity.

Dial In The Grind For Your Product Type

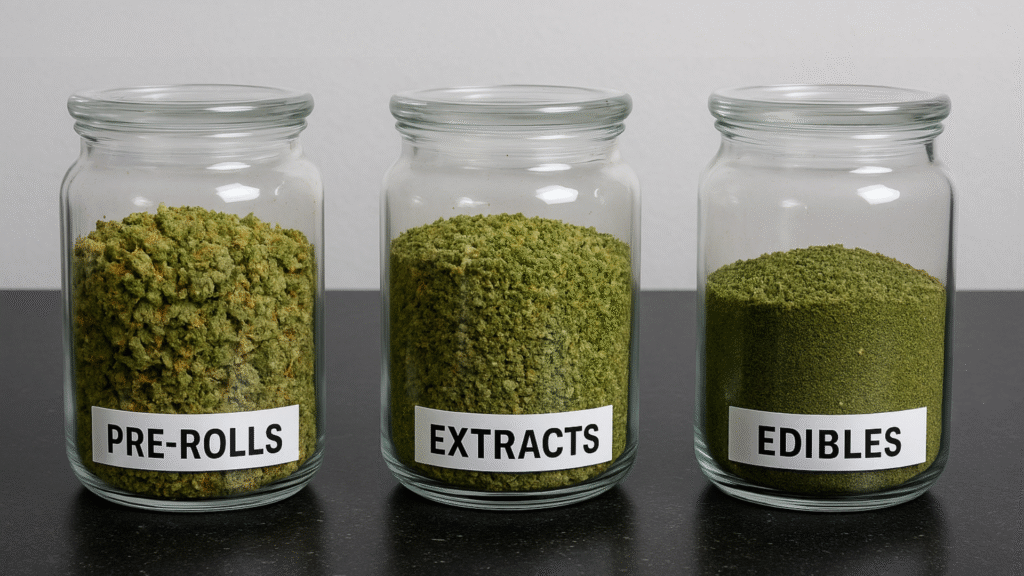

Finally, it’s essential to understand that different cannabis products will require different grind types. For pre-rolls, a medium-coarse grind ensures even airflow and smooth burning, without the risk of canoeing. For extraction, a less coarse grind can increase surface area, supporting efficient cannabinoid and terpene coverage, while edibles can benefit from a finer grind.

Regarding various strains, every cultivar has its unique characteristics that operators should test and adjust flower grinder settings to match. Factors like density, moisture level, overall stickiness, and other characteristics can influence how a flower grinds, no matter the type of grinder that’s used.

So, selecting equipment that gives you the ability to fine-tune grind size for various product types not only supports higher quality products, but also scalability with SKU expansion capabilities.

ROI Of Commercial Cannabis Grinders

Last but not least, commercial cannabis grinders can be a shocking initial investment. However, when looking at the ROI its operational gains can provide, it can lessen the blow. A few advantages that automating cannabis grinding can provide include:

- Reduced labor

- Accelerated throughput

- Less manual handling

- Consistent, uniform output

- Less material loss

- Tighter weight control

- Fewer quality control issues

Most importantly, grinders specifically designed for low-friction operation, like the TerpPreserve, can improve a brand’s reputation, resulting in stronger brand loyalty, and improved profit margins and bottom lines.

Final Take: If You Want Precision, You Start With The Grind

In the end, if you’re seeking consistent quality and precision, it all starts with the grind. In today’s cannabis industry, there’s one manufacturer you can count on for both: Hefestus, the House of Automation. Hefestus is the leading provider of cannabis automation and manufacturer of the TerpPreserve, the commercial cannabis grinder choice of top producers globally.

Preserve your product’s integrity by maintaining the flower’s natural terpene profiles while grinding to a consistent size for the utmost quality in experience. The TerpPreserve was built with both quality and efficiency in mind, and is designed to support the throughput and reputation of operations, no matter the SKUs or markets they serve.

Learn more about how to grind bud efficiently and successfully with Hefestus’ TerpPreserve Grinder now.