Dutch Fold vs. Twist Fold: What’s the Best Pre-Roll Finish?

When it comes to the cannabis industry, there are personal and professional preferences, especially for consumption methods as personal as smoking a joint. Pre-roll joints know this all too well. As one of the fast-growing product categories, the competition is fierce. Leaving many growing brands wondering, What’s the best pre-roll finish?

Preroll packaging, whether Dutch Crown joints or twist-fold, can make a considerable difference in terms of brand loyalty. In a fiercely competitive industry, this means conducting thorough due diligence to understand how to close a pre-roll cone and just how joint packaging will impact the end consumer.

The best place to start? In this guide, we’ll cover different ways to roll a joint, specifically focusing on the final step: closing it, and the preferences of consumers surrounding it. So, keep reading to learn more about how to roll a Dutch fold vs twist fold joint, and all the implications the type of roll has for performance, packaging, and perception.

Why Pre-Roll Finishes Matter

To start, why does pre-roll packaging or finishes matter? Because no matter the product or case, first impressions matter. If a pre-roll looks lazily manufactured, with a loose finish, it can immediately indicate a negative perception of the quality and craftsmanship. For pre-rolls especially, neatness in rolling indicates a premium product, while a sloppy finish is the opposite.

Functionally, the pre-roll finish matters even more. Because the final step of rolling or filling a pre-roll cone is closing the end, this ensures a few essential roles for smoking it successfully. First, and foremost, the finish protects the flower inside, keeping it contained from spilling out. The way in which it’s folded or finished will also affect the burn consistency.

All in all, making sure a pre-roll cone or joint doesn’t unravel or spill isn’t just about consumer preference or quality. It’s about passing regulations and requirements, too. Lastly, beyond maintaining integrity for compliance sake and consumer impressions, unique finishes can also work to set your brand apart, with a signature look becoming your tool for brand differentiation.

What Is a Dutch Fold (aka Dutch Crown)?

Speaking of finishes and folds, let’s get into one of the most popular pre-roll packaging types: the Dutch crown joint, or Dutch fold method. For a bit of history, this type of fold came from our friends across the pond, in Europe, and has recently been adopted in legal cannabis markets in the US and beyond.

Rather than using a twist method, which can unravel, the Dutch crown joint creates a secure closure. It’s standard for the legal industry, making it the most sleek and professional option on the market today. However, with some brands still opting for the twist method, a Dutch crown joint is still associated with higher-end, or premium products.

How To Roll A Dutch

So, how to roll a dutch on your own? The manual technique involves gently folding over and tucking the excess paper over itself until it’s flat. Start on one side, fold the paper down, and continue around the circle until complete. In the end, the final form resembles a crown, hence its namesake.

Unlike twisting, this method does pose some challenges for everyday rollers. To avoid crumpling or tearing of the final delicate paper, it requires patience, skill, or practice to get it just right every time.

For hand rollers, it can be nearly impossible to make every pre-roll uniform with the Dutch method, but have no fear – fill and fold pre-roll machines exist for commercial purposes (stick around: we’ll cover the industry-leading equipment by the end of this guide!).

What Is a Twist Finish?

A twist finish is also easy to recognize, as it’s evident from the final end-product that the paper has been twisted. A twist finish is when the end of the pre-roll cone or joint paper is twisted until closed completely, creating a small “wick” or tip at the end for lighting. This is also one of the most recognizable finishes, as it’s commonly associated with traditional hand rolling or DIY seshes, with quickly rolled joints.

While Dutch crown joints are most associated with professional, premium products you buy at a dispensary, the most functional benefit is that it’s easy to do so yourself, and close by hand. It also safely and securely protects from spillage during transport, but it does come with a few drawbacks. While it’s appropriate for casual joints, it often causes uneven burning or canoeing, which consumers would rather not pay for when purchasing a pre-roll.

How To Do A Twist Finish

If you’ve learned different ways to roll a joint, you’re likely familiar with how to do a twist finish. Simply pinch and twist the extra paper tightly above the flower at the end of the joint paper or pre-roll cone. This is often the first method that new rollers learn, making it highly familiar among consumer groups.

Unfortunately, on the retail side, twists can loosen in transport or flatten in packaging, making them not ideal for commercial production. Furthermore, most equipment used to produce bulk amounts of pre-rolls cost-effectively are fill-and-fold pre-roll machines that specialize in the Dutch Crown method, which legal consumers also prefer. Today, twists are, for the most part, reserved for hand rolling or small batch production situations.

Dutch Fold vs Twist Finish

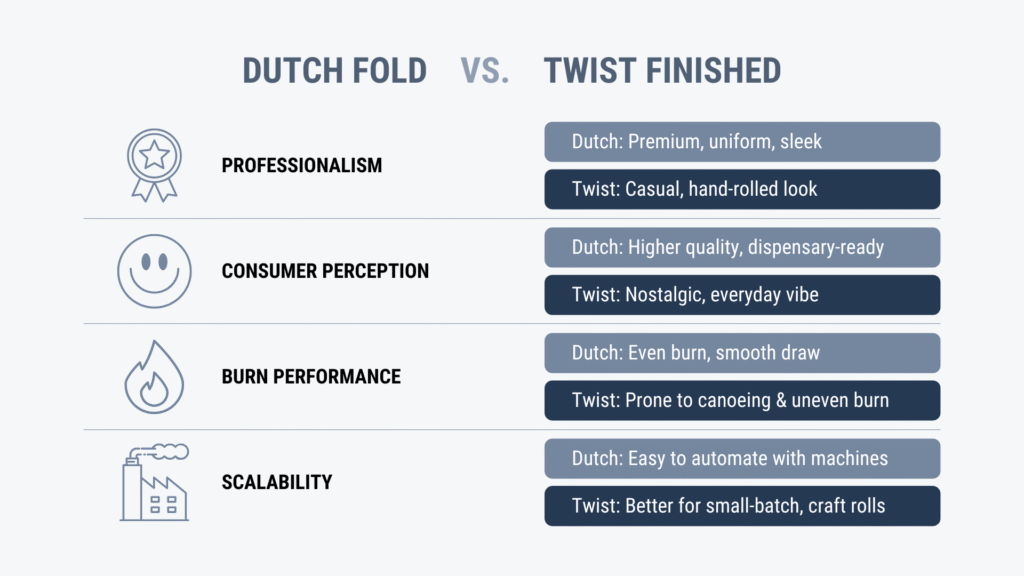

Still unsure of which pre-roll packaging and finish is right for your operation? Let’s summarize all of the differences to help you get a better idea of the comparison.

- Professionalism: Dutch crown joints or Dutch fold pre-roll cones are more professional than twist joints, thanks to their premium aesthetic and uniform look. Twist joints are considered inconsistent and more casual among consumers.

- Consumer perception: Speaking of consumers, the more professional, premium look signifies higher quality overall, while the twist method appeals to nostalgic or everyday use, which does not qualify as a luxury experience.

- Burn performance: Twisted joints have a higher probability of producing an uneven burn, thanks to an uneven light. This results in hotspots throughout the smoking experience, frustrating the end-consumer. On the other hand, even novice consumers can light a Dutch Crown joint evenly, resulting in a smooth and even burn experience.

- Brand positioning: That said, if you’re seeking to position your brand as budget-friendly or “authentic” as a craft-style brand, you may opt for the nostalgic twist finish. In general, Dutch crown joints signify an upscale experience, and are more common for higher quality and priced pre-rolls found in dispensaries from leading brands.

- Scalability: Finally, if you’re seeking to scale your processes and production, the Dutch Fold method is far easier to automate with fill-and-fold machines, such as those from Hefestus. Twist joints are best suited for hand-rolled craft production.

How Pre-Roll Packaging Finish Impacts Your Brand

As you can tell from the points above, the pre-roll packaging finish you choose ultimately will affect your brand and its perception by consumers. To start…on the shelf, Dutch crown joints give off a clean, premium aesthetic that’ll attract consumers seeking a high-quality experience in competitive markets.

On screen, the Dutch fold is also the “Instagram-worthy” choice for product shots, just as it is in person. In the package, twist finishes can also create issues where bulging occurs or uneven pack outs, thanks to the extended length the “wick” creates. Instead, Dutch crown joints are packed inward, allowing them to fit snugly in most standard packaging.

Finally, uniform finishes, compliments of Dutch crown folds, reassure buyers of professionalism and consistency across batches. For compliance sake, you can help your operation avoid costly fines and prevent loose product in child-resistant packaging by opting for the Dutch crown fold versus the twist.

Which Finish Is Right for You?

Simply put, if you’re operating in a legal state or national market and want your brand to be taken seriously, there’s no other choice than Dutch Crown joints. All in all, twisted finishes give a casual, everyday, or DIY aesthetic that won’t command a favorable brand reputation or loyalty, especially amongst everyday consumers or connoisseurs.

Of course, if you’re a small-batch craft producer that’s seeking a casual or hand-rolled brand image, then you may consider twist finishes for how to close a pre-roll cone that you produce. Just be aware that as cannabis markets mature, brands often move toward Dutch Folds for consistency and premium appeal, which can help future-proof your business.

Get Hefestus Fill And Fold Pre Roll Machine

Now that you know all about preroll packaging, specifically how to roll a Dutch commercially, it’s time to explore fill and fold pre-roll machines for your operation. Facilities across the globe are investing in their joint packaging efficiency to produce not only consistent, higher-quality products, but also to scale exponentially.

For reliable, consistent results, look no further than the House of Automation, Hefestus, and equipment designed specifically with the cannabis industry (and its challenges!) in mind. No twisting from this machine, as it expertly tamps and folds every tip with a dutch crown joint finish that consumers prefer.

Even better? The AuraX, automatic fill and fold pre-roll machine from Hefestus, not only improves your speed, consistency, and presentation, but also helps reduce labor costs to protect your margins and bottom line. It’s the best automated pre-roll machine on the market in terms of both versatility and economics. In fact, many facilities have seen a 90% cut in labor costs, thanks to its ability to fill 1500+ pre-rolls per hour (which equals nearly $1300/a shift).

Lastly, the Aura X is flexible, with the ability to seamlessly transition from paper size to paper type. Giving operators the ability to expand their product collection to include various pre-rolls, from filling dog walkers in the morning to 2-gram blunts in the afternoon, Hefestus gives you the power to do so cost-effectively and with the peace of mind that comes with quality results.

Interested in optimizing your facility’s joint packaging? Schedule a demo or connect with Hefestus at the next industry event. Get in touch with our team now!