Terpene Infused Pre-Rolls: How Modern Technology Protects Their Profiles

As the cannabis industry continues to evolve, so do the tastes and preferences of its consumers, as well as their knowledge. That means there are more discerning buyers on the market today than ever before, demanding flavorful, potent, and quality experiences. This is where terpene-infused pre-rolls enter the conversation.

Terpene-infused cones aren’t just a fleeting trend; they’re the mark of the future for consumers seeking these types of experiences and manufacturers seeking to deliver on demand. Of course, thanks to the volatility of these precious compounds, terpene preservation is made that much more difficult throughout the manufacturing process.

So, just how do modern-day terpene technologies support the future of cannabis pre-roll processing? This guide will answer that question and more as we delve into how modern technology safeguards the natural profiles of terpene-infused joints. Keep reading to not only learn “what is terpene infused cones” but also how to deliver quality SKUs in the category.

Why Terpene Preservation Matters

Before we get into the terpene technologies behind today’s pre-roll production, let’s first cover why terpene preservation matters. First and foremost, it’s essential to understand precisely what terpenes are and more about their composition. Terpenes, or “terps,” are aromatic compounds produced by plants (including cannabis) that give them their unique aromas.

With cannabis plants, every cultivar or strain has a distinct profile of terpenes that contribute to its individual aroma, flavor, and effects. That’s right, not only do terpenes give cannabis its signature scent, but they also have their own individual mechanisms that create unique effects. Such as the terpene linalool (also found in lavender), lending to a sleepy or sedating buzz.

These are the two primary reasons why terpene preservation matters. Not only does protecting the plant’s natural profile preserve the strain’s integrity, but it also preserves the flavor and effects the consumer intends to experience. Lastly, the reason why terpene preservation is so difficult to achieve is the volatility of the compounds.

As practically microscopic compounds, terpenes can degrade or evaporate completely under certain conditions, such as with heat or agitation. This makes the handling of the material during cannabis pre-roll processing that much more important to protect the result for the consumer, who expects the highest level of flavor.

Why Some Pre-Rolls Taste Better

Terps are exactly why some pre-rolls taste better than others. Hence, the importance of handling the flower material with care, to keep the natural profile as intact as possible. To get a better idea of the terps behind each of the plant’s most notorious aromas, here’s a look at the most abundant cannabis terpenes you’ll find in the strains of today:

- Myrcene: Earthy, musky, and herbal

- Caryophyllene: Woody, spicy, and peppery

- Limonene: Lemon, orange, citrus

- Pinene: Pine, herbal, woody

- Linalool: Floral and spicy

- Humulene: Hoppy, earthy, woody

Technologies Behind Terpene Preservation

From cultivation to extraction, several technologies are behind the art of preserving terpenes, all with one goal in mind: low-impact processing. Due to the delicate nature of terpene molecules, at every step of the process, especially for cannabis pre-roll processing, the flower material must be handled with care.

A few of the key technologies used in today’s cannabis industry include:

- Nitrogen-pressurized paths for extracts, which reduce oxygen exposure and oxidation.

- Low-heat grinding systems that minimize terpene evaporation for filling pre-rolls.

- Closed-loop processing environments that shield compounds from open air.

All of the above work to protect the flower or extract material from exposure to oxygen, light, and high temperatures, all of which can degrade terpenes.

Terpene Extraction And Infusion Methods

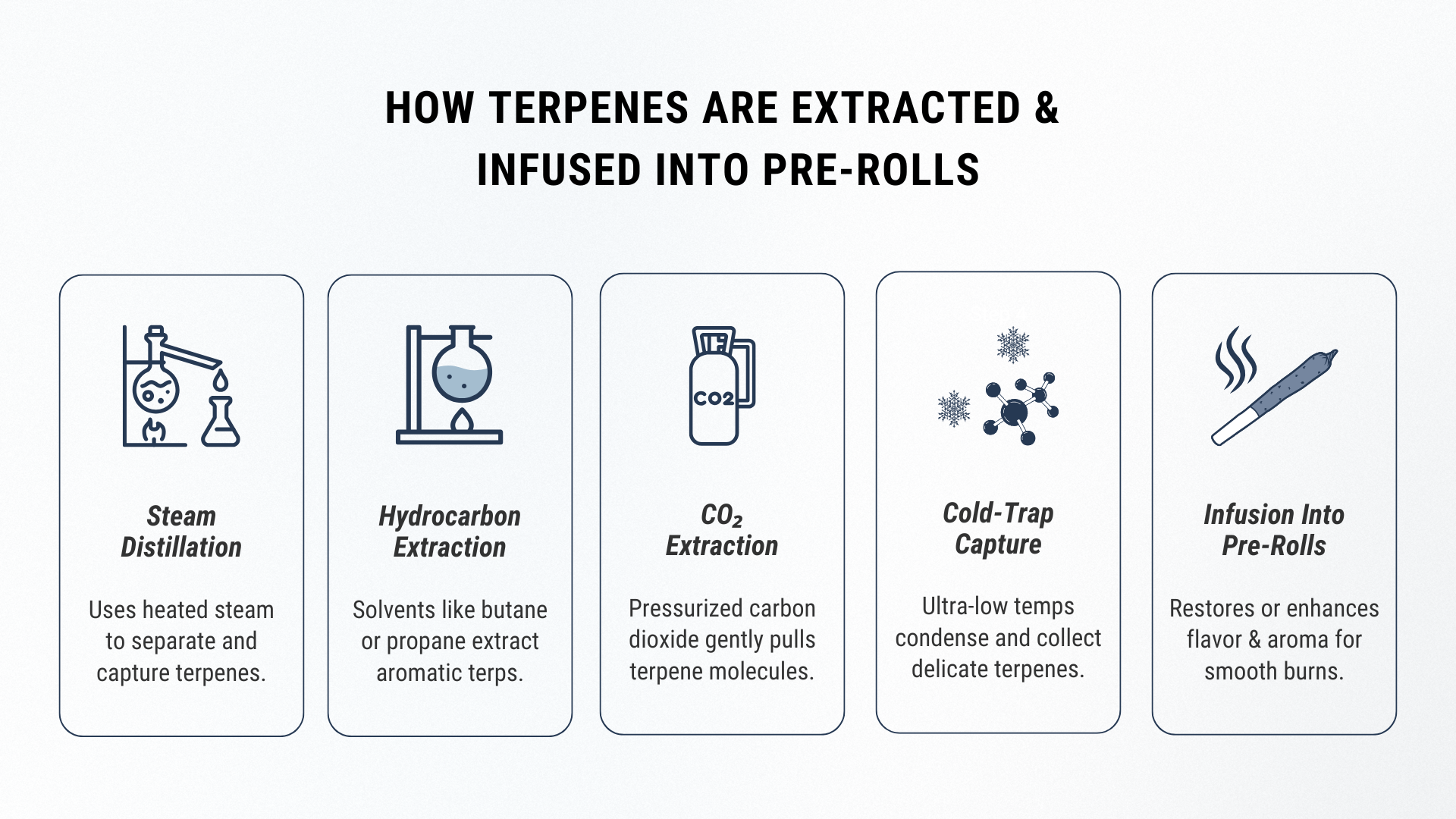

It’s also possible to extract terpenes from flower material and infuse them into pre-rolls to further enhance the flavor. To do so, there are a variety of different extraction methods that address stability challenges with the delicate compounds. Those including:

- Steam distillation: This method uses heated steam to vaporize and separate terpenes from plant material, then condenses them back into liquid form.

- Hydrocarbon: This type utilizes solvents such as butane or propane to dissolve and extract terpenes and cannabinoids, resulting in highly aromatic concentrates.

- CO₂: Instead of hydrocarbons, the CO₂ method uses pressurized carbon dioxide in supercritical or subcritical states to gently pull terpenes with minimal residue.

- Cold-trap capture: As the name suggests, this method collects terpenes by condensing them at ultra-low temperatures during processes such as drying, curing, or extraction.

Once extracted or separated, terpenes can be infused into pre-roll cones via spraying or misting them into the flower material. This can either help restore natural terpenes lost in the process or enhance them even further. Of course, it’s essential to be careful with application and dosing, as too many added terps can cause harsh or uneven burns.

Pre-Roll Machinery Innovations

When it comes to producing terpene-infused pre-rolls, quality is the endgame, but so is efficiency for the operation’s bottom line. Hence, the innovation of pre-roll machinery to support the facility’s ability to produce premium terpene-infused cones at a rate that keeps up with retail demand and saves on rising labor costs. To help the process, leading manufacturers across the US are integrating advanced pre-roll machinery into their production lines, including:

- Grinders: Hand grinders are labor-intensive and high-friction, as are commonly used mills. Instead, many are transitioning to precision, low-temp industrial grinders that protect trichomes and terps.

- Automated Infusers: New machines meter terpene oils or isolates into ground material or directly into cones.

- Rolling and Filling Machines: From early hand-pack systems to automated pre-roll fillers (like the Hefestus AuraX), machines help preserve material quality while scaling output.

All in all, infusing or spraying terpenes and filling pre-rolls is a laborious process. By implementing today’s available terpene technologies and advanced machinery, operators can deliver on both quality and efficiency, allowing them to scale more easily.

Packaging Tech

Another critical factor to consider when producing terpene-infused joints is the packaging in which they’ll be sold. Terpene preservation extends beyond the manufacturing stage, and degradation can occur while the product is in its packaging for sale. To protect against further degradation, air-tight seals, UV-blocking films, and humidity control packs are often employed.

The popularity of terpene-infused cones is also prompting operators to transition from generic plastic or paper packaging to cannabis packaging that is ideal for terpene protection, such as glass or specialized materials specifically designed for preservation. Remember, packaging isn’t just to make the product look good or “fancy”, it’s there to preserve the product inside.

Lastly, technology is also assisting the processing package to make the process of preserving terpenes seamless. This includes automated equipment that is capable of locking in the freshness immediately after rolling, packing, or infusing flower material with terpenes in either jars or bags.

Automation And Consistency In Pre-Roll Production

Another factor that’s important to consider when improving your pre-roll production is the quality of the equipment you choose to upgrade to. It’s not just output you’ll want to consider, as you can negatively affect your brand name by outputting high amounts of inventory with low quality. Instead, you’ll want to seek out equipment that can deliver both: industrial scalability and premium results.

Automation isn’t just a tool to reduce human errors or variability in pack density or terpene loss: it’s there to provide consistency of quality to the end-consumer. Keep in mind that consistency is key to nurturing and maintaining customer loyalty and retention, with the promise of reliable, even burns with every terpene-infused joint consumers purchase.

That’s why leading global and US operations turn to Hefestus as the bridge between craft quality and commercial scale, ensuring brands meet consumer demand while maximizing efficiency and productivity.

Choosing The Right Machines For Terpene Preservation

Simply put, not all cannabis pre-roll processing machines can be treated equally – especially those without terpene technologies to protect and preserve the precious compounds. Hefestus, the House of Automation, is behind the industry’s leading collection of equipment designed to prioritize terpene preservation.

From our Terp Preserve industrial cannabis grinder to the Aura X, our automated pre-roll machine, product quality products (efficiently) is top of mind. Since terps = quality in the mind of the consumer, Hefestus prioritizes terpene preservation, allowing cannabis brands across the US to output high-quality products at high profit margins, thanks to lower labor costs.

If you’re ready to improve your terpene-infused pre-roll operations or add terpene-infused cones to your current SKUs with the best pre roll machine, there’s only one place to start: Hefestus. Learn more about our brand and history to empower your product’s potential, and get in touch to schedule a one-on-one consultation for your growing operation.