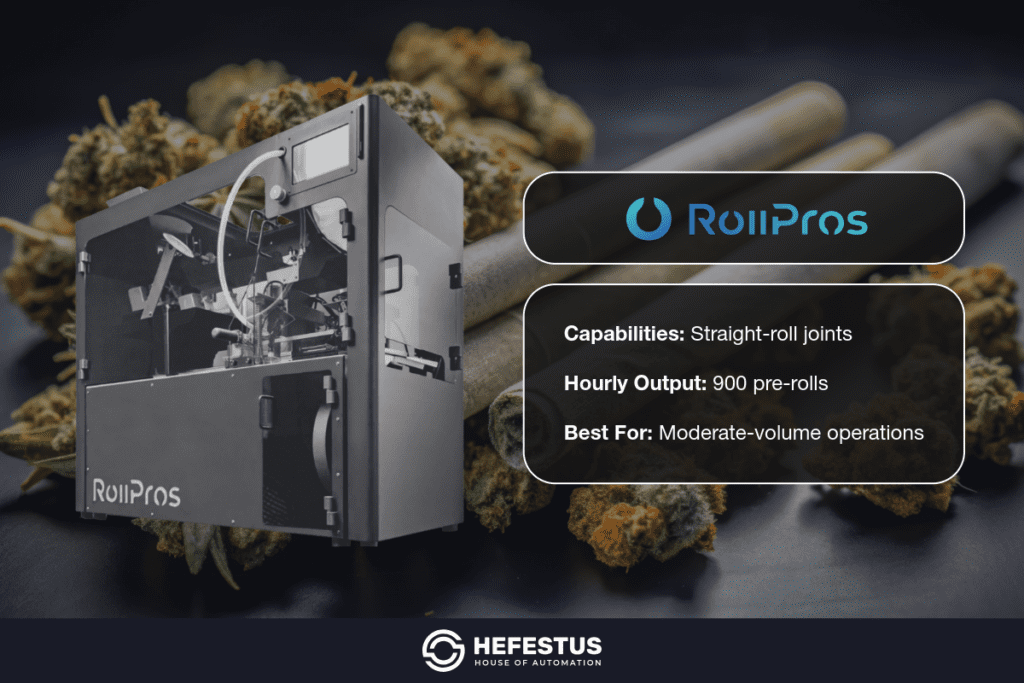

RollPros Blackbird Review [2026]

If you’re considering the RollPros Blackbird, you’re likely looking to move beyond pre-roll cones and produce straight pre-rolls with more control over materials and cost.

The Blackbird rolls joints using bobbin paper and crutches instead of pre-formed cones, giving operators flexibility in size, paper, and branding while keeping labor simple with a single-operator setup.

In this review, we’ll break down what the Blackbird does well, where it starts to limit growth, and how it compares to higher-capacity systems.

What Is the RollPros Blackbird?

The RollPros Blackbird is a commercial pre-roll machine that rolls straight joints instead of stuffing cones.

It uses raw paper from a bobbin and separate crutches, giving operators direct control over joint size, materials, and presentation.

The system relies on RollPros’ TruRoll technology, which uses a platen and belt to roll each joint with adjustable tension and density.

Settings can be dialed in through the touchscreen and saved for repeat runs across similar strains, batches, or weights.

The Blackbird runs terpene-rich flower from a top-mounted hopper that holds up to 1.5 pounds and can be refilled without stopping the machine.

In standard operation, it produces two joints per cycle and averages around 900 pre-rolls per hour, depending on material prep and operator tuning.

It runs on standard 110V power, weighs about 480 pounds, and is compact enough to move through a standard doorway, making installation easier in existing production spaces.

Key specs at a glance:

- Output: ~900 pre-rolls per hour

- Power: 110V, 15A Weight: ~480 lbs

- Dimensions: 48″ H × 41″ W × 29″ D

- Joint diameter: 6–9.5 mm

- Joint length: 70 mm

- Recommended moisture: 10–12%

- Recommended grind: coarse, fluffy

How the RollPros Blackbird Works

Here’s a quick breakdown of how the Blackbird works:

- Crutches are loaded into the system first. The machine supports multiple crutch materials, depending on the product being produced.

- Paper is loaded in bobbin form and fed automatically into the rolling system. The paper is formed, wrapped, and sealed in-line during production.

- Flower is loaded into the hopper and refilled as needed during production.

- Roll tension, density, and diameter are adjusted through the touchscreen interface. These settings can be saved and reused for repeat runs.

- Once running, the platen and belt system rolls two straight pre-rolls per cycle. One operator typically handles refills, monitoring, and minor adjustments during production.

Pros of the RollPros Blackbird

The RollPros Blackbird offers several key advantages:

Straight Roll Production

The Blackbird rolls joints instead of filling cones, making it a strong fit for brands that want a traditional straight pre-roll format rather than a cone-based product.

Lower Consumable Costs

By using bobbin paper instead of pre-formed cones, the Blackbird reduces reliance on cone inventory and cuts per-unit consumable costs, especially at higher volumes.

Product Customization

Operators can adjust joint diameter, paper type, crutch material, and overall presentation, making it easier to differentiate products without custom cone orders.

Single-Operator Workflow

The machine typically runs with one operator handling refills, monitoring, and basic quality checks, keeping labor requirements manageable.

Compact Footprint

The Blackbird is relatively compact for a commercial rolling system and can move through standard doorways, making it easier to install in existing production spaces.

Consistent Rolling

The platen and belt system produces uniform, straight pre-rolls with repeatable density and airflow once settings are dialed in.

Cons of the RollPros Blackbird

However, the Blackbird also has some drawbacks:

Throughput Ceiling

The Blackbird delivers solid output for straight-roll production, but its hourly capacity is lower than fully automated systems built for high-volume facilities.

Operator-Dependent Tuning

Material prep and settings matter. Consistent results depend on having an operator who can dial in tension, density, and feed as material characteristics change.

Straight-Roll Focus

The machine is designed specifically for straight pre-rolls. Operations that need cones, blunts, or a wider range of formats will need additional equipment or a different system.

Limited Headroom for Growth

As monthly volumes climb and SKU counts expand, the Blackbird can start to feel constrained compared to higher-capacity automation designed for scale.

Less End-to-End Automation

While rolling is automated, upstream and downstream steps still require manual handling, which can limit overall line efficiency in larger operations.

Who the RollPros Blackbird Is Best For

The RollPros Blackbird is best if you have an operation focused on straight roll production and want more control over your production compared to hand-rolling or using a semi-automatic process.

The Blackbird fits teams producing moderate monthly volume that are comfortable running a dedicated operator and tuning the machine as material changes.

If your brand is building a straight-roll SKU lineup and you don’t plan to expand into multiple formats, the Blackbird is a practical choice.

Is the RollPros Blackbird Worth It?

The value of the RollPros Blackbird comes down to what you want out of your production line.

For straight pre-roll production, it offers a different cost structure than cone-based systems and avoids ongoing dependence on pre-formed consumables. That alone can make the numbers work for certain operations.

Where the return starts to flatten is at higher volume or increased complexity. Output, format range, and overall automation depth don’t scale at the same rate as larger systems built for enterprise production.

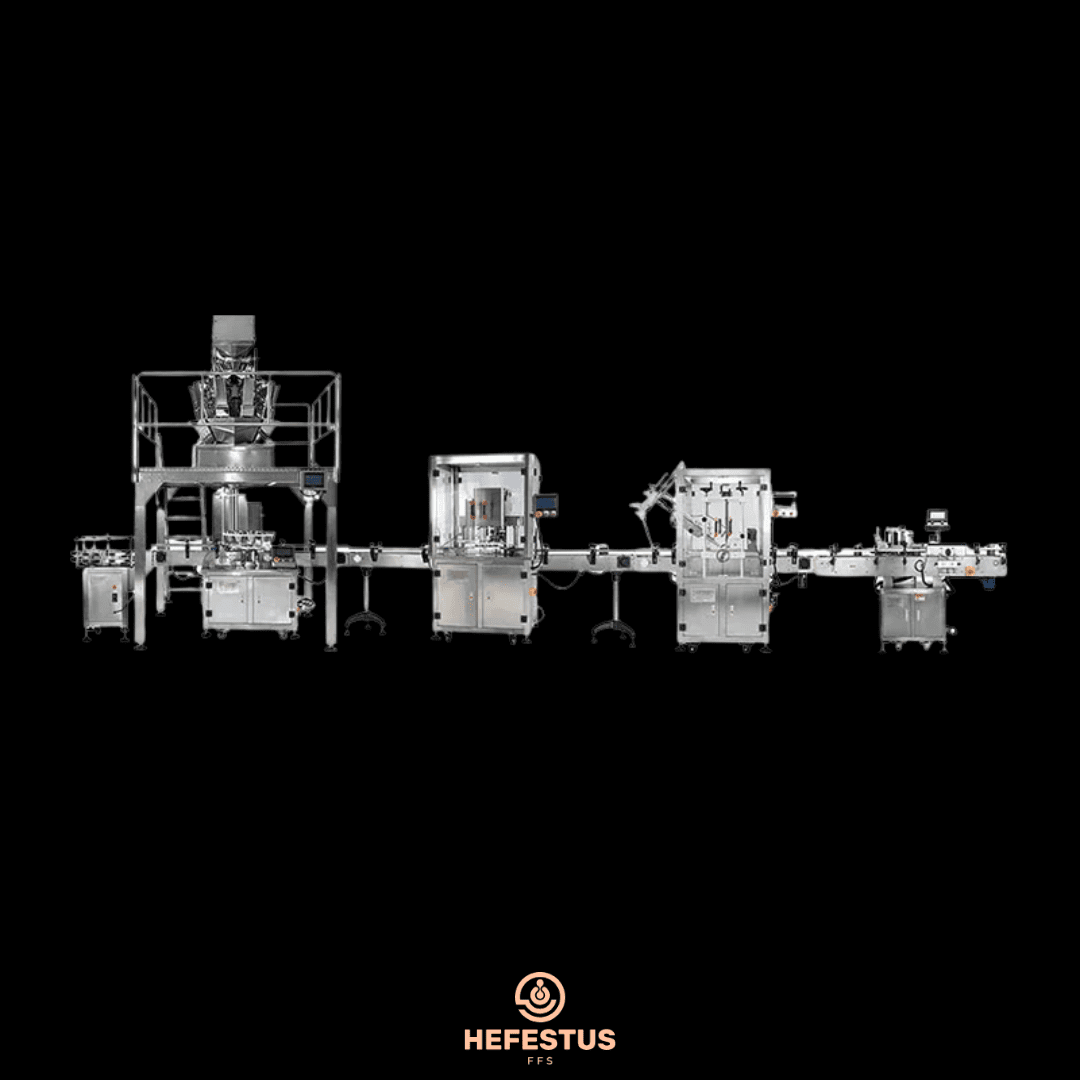

If straight rolls and consumable control are priorities, the Blackbird can justify the investment. If your roadmap includes higher throughput, multiple formats, or line-level automation, more scalable, versatile systems – like the Hefestus AuraX – tend to make better long-term sense.

RollPros Blackbird vs. Hefestus Aura X: When It’s Time to Upgrade Your Pre-Roll Line

The Blackbird and the AuraX aren’t direct substitutes – they’re built for different stages of production.

The Blackbird focuses on rolling straight joints with low consumable costs and hands-on control. It works well if all you need to do is roll cigarette-style joints and don’t need high-volume, multi-variant production.

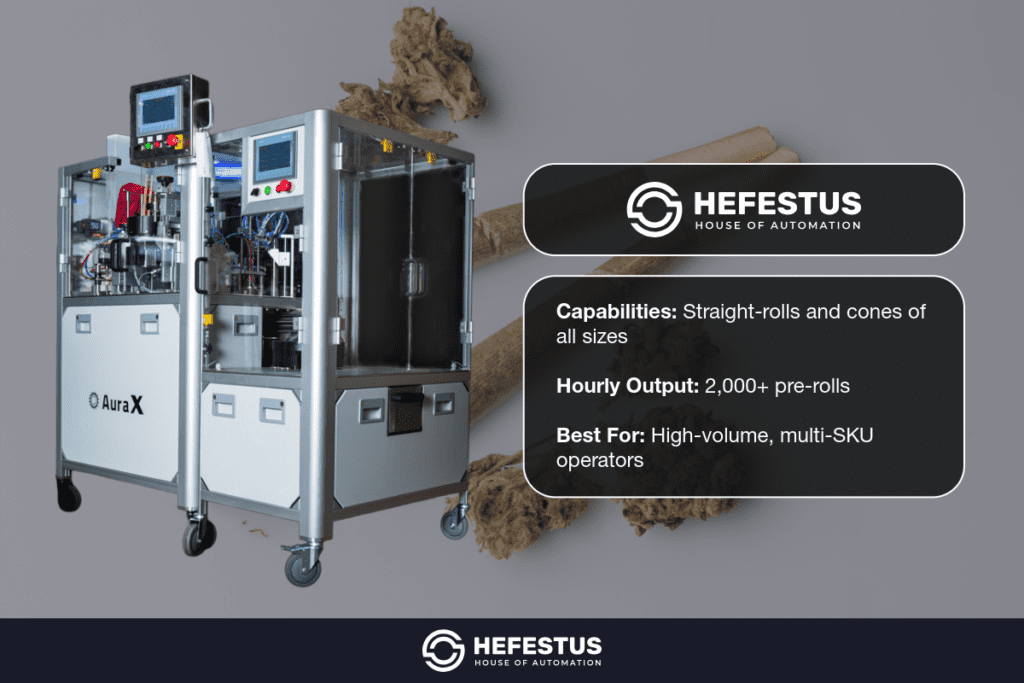

The AuraX is built for when your production needs to expand – both in volume and in variety. It’s a fully automated system designed to reduce manual touchpoints, increase hourly output, and support multiple pre-roll formats on a single machine.

For many operators, the question isn’t which is better – it’s when one starts to make more sense than the other.

Quick Comparison

| Feature | RollPros Blackbird | Hefestus AuraX |

| Primary Use | Straight pre-roll | Full-spectrum pre-roll automation |

| Formats Supported | Straight roll | Cones, straight rolls, blunts, infused |

| Typical Output | ~900 pre-roll/hour | 2,000+ pre-rolls/hour |

| Consumables | Bobbin paper and crutches | Cones, straight rolls, infused inputs |

| Typical Price | ~$225,000 | ~$230,000 |

| Best Fit | Moderate volume, straight-roll SKUs | High volume, multi-SKU operations |

Conclusion: Choosing the Right Pre-Roll Solution for Your Operation

The RollPros Blackbird makes sense for a certain kind of operation. It supports straight pre-roll production, your team control over materials, and keeps consumable costs manageable at moderate volume.

For many producers, that’s exactly what’s needed. The Blackbird can run consistently and do the job it’s meant to do without adding extra complexity.

Over time, needs can change. Volume increases. Product lines grow. Efficiency starts to matter more.

When that happens, it’s about moving on to the next step – the Hefestus AuraX. This robust automation system is built for higher output and broader automation when production starts moving in that direction.

RollPros Blackbird Review: Frequently Asked Questions

If you’re looking at the RollPros Blackbird, these are some of the questions that usually come up.

How much does the RollPros Blackbird cost?

RollPros does not publish pricing publicly. The Blackbird is typically priced around $225,000. Final pricing is confirmed directly with RollPros.

How many pre-rolls per hour can the Blackbird produce?

The Blackbird is rated at around 900 pre-rolls per hour, with actual output varying based on material prep and operator tuning.

Does the Blackbird work with infused flower?

The Blackbird can run some types of infused flower within its supported range, though consistency depends on the type of infusion and material preparation.

Is the Blackbird fully automated?

No. Rolling is automated, but the system still relies on an operator for material loading, monitoring, and adjustments.

What’s the difference between the Blackbird and Blackbird XXL?

They use the same rolling system, but the Blackbird runs standard straight pre-rolls, while the Blackbird XXL is built for larger diameters, heavier weights, and blunt-style formats.