APEHEX Pre-Roll Machine Review [2026]

If you’re running pre-roll production by hand or juggling a semi-automatic setup, you already know where the bottlenecks show up: inconsistent cones, labor headaches, and limits on how much you can realistically produce in a day.

The APEHEX pre-roll machine is often the next step for teams like yours. It promises faster output, cleaner cone finishes, and a smoother path into automation without the footprint or cost of a full enterprise system.

In this review, you’ll see what the APEHEX delivers in real production, where it starts to fall short, and how it compares to other options on the market once scale and SKU variety become the priority.

What Is the APEHEX Pre-Roll Machine?

The APEHEX pre-roll machine is an automated cone-filling system built for producers who want to move past hand-packing without overhauling their entire facility.

It’s designed to be run by a single operator and fits easily into small production rooms, making it a practical upgrade for growing teams. APEHEX automates the most time-consuming part of pre-roll production: loading, filling, weighing, and finishing cones.

You load pre-made cones, add prepared flower, dial in your target weight, and the machine handles the rest delivering a consistent Dutch crown finish that’s ready for packaging.

APEHEX is built specifically for cone-style pre-rolls, with supported weights ranging from 0.3g up to 1.25g. Output is rated at up to 1,100-1,200 pre-rolls per hour, depending on material and setup.

Like most machines in this category, throughput varies, but it’s a major step up from manual or semi-automatic workflows. The system runs on standard 110V power and compressed air, rolls on wheels for easy positioning, and doesn’t require major facility upgrades to install.

If you’re looking for a way to automate cone production quickly and efficiently without committing to enterprise-scale automation, the APEHEX is made for that role.

How the APEHEX Works

The APEHEX is designed to keep production straightforward, even with a small team. Once it’s set up, a single operator can manage the entire workflow.

- Load the cones: You start by loading pre-made cones into the tube-loading system. The APEHEX is compatible with most machine-made cones, so you’re not locked into a single cone supplier. Bulk loading keeps changeovers quick and downtime minimal.

- Add the flower: Next, you add pre-ground, properly prepared flower into the machine’s lanes. The APEHEX distributes material evenly and weighs each cone to your target specification, helping maintain consistent density and airflow across runs.

- Dial it in and run: Using the touchscreen interface, you fine-tune weight, pack pressure, and finish. Once dialed in, the machine compacts and finishes each pre-roll with a clean Dutch crown fold, producing uniform, retail-ready cones with minimal hands-on work.

Pros of the APEHEX

Easy Step Into Automation

If you’re coming from hand-packing or semi-automatic equipment, the APEHEX feels approachable. It’s simple to operate, doesn’t require a large team, and helps you automate cone production without reworking your entire facility.

Compact, Space-Efficient Design

The small footprint makes it easy to fit into tight production rooms. It’s on wheels, easy to reposition, and works well in facilities where floor space is already at a premium.

Single-Operator Workflow

Once you’re up and running, one person can manage the machine. That cuts down on labor costs and reduces the coordination issues that come with multi-station setups.

Clean, Consistent Cone Finish

The Dutch crown fold gives your pre-rolls a polished, retail-ready look. When the machine is properly dialed in, cones come out uniform in weight, density, and appearance.

Straightforward Setup and Training

APEHEX includes five days of on-site training to get your team comfortable with operation and dialing in settings. That helps shorten the learning curve and gets production moving faster.

Low Facility Requirements

The machine runs on standard 110V power and compressed air, so you don’t need major electrical upgrades to install it. That makes it easier to deploy quickly.

Flexible Purchasing Options

With buy or lease options available, the APEHEX gives you flexibility in how you bring automation online, especially if you’re trying to manage cash flow during a growth phase.

Cons of the APEHEX

Throughput Limits

While the APEHEX is a big upgrade from manual filling, actual output typically falls below its top-end rating once setup, material prep, and tuning are factored in. As demand increases, it’s easy to hit a ceiling that limits how much you can scale on a single shift.

Cone-Only Production

The APEHEX is made specifically for cones. If you plan to expand into straight rolls, blunts, oversized formats, or specialty shapes, you’ll need additional equipment or a higher-capacity system.

Infusion Constraints

The machine can run infused flower, but only within tight limits. Heavier infusions, higher viscosity materials, or more complex infused SKUs quickly push beyond what the system is designed to handle.

Limited SKU Flexibility

If your roadmap includes frequent SKU changes or new product launches, the APEHEX can start to feel restrictive. It’s effective for doing one thing well, but less adaptable as your product mix evolves.

Lighter Ongoing Support

Initial training gets you up and running, but ongoing optimization and troubleshooting rely more on your internal team compared to systems that offer round-the-clock technical support.

Who the APEHEX Is Best For

The APEHEX is a good fit if you’re running a boutique or lower-mid volume operation and want to replace hand-packing with reliable automation without overbuilding your line.

It makes the most sense if you’re producing roughly 10,000 to 20,000 pre-rolls per month, focused primarily on cone-style products, and looking to reduce labor while improving consistency.

If your facility space is tight or you don’t want to deal with electrical upgrades, the APEHEX’s small footprint and simple utility requirements are a plus.

You’ll get the most value out of it if your product lineup is fairly stable and centered on dry flower or light infusions. For teams that want a straightforward, single-operator system to handle day-to-day production, the APEHEX does exactly what it’s built to do.

If your growth plans include higher monthly volumes, heavier infusions, or expanding into multiple formats, the APEHEX can start to feel limiting. In those cases, a higher-capacity platform is better suited for long-term scale.

Is the APEHEX Worth It?

The value of the APEHEX comes down to what you want out of your production line right now.

For cone-focused production, it offers a straightforward path into automation without the cost or footprint of a full enterprise system. If you’re currently relying on hand-packing or semi-automatic tools, the labor savings and consistency gains alone can justify the investment.

Where the return starts to flatten is as volume and complexity increase. Output caps out quickly compared to higher-capacity systems, and the lack of format flexibility limits how much additional revenue you can generate from new SKUs.

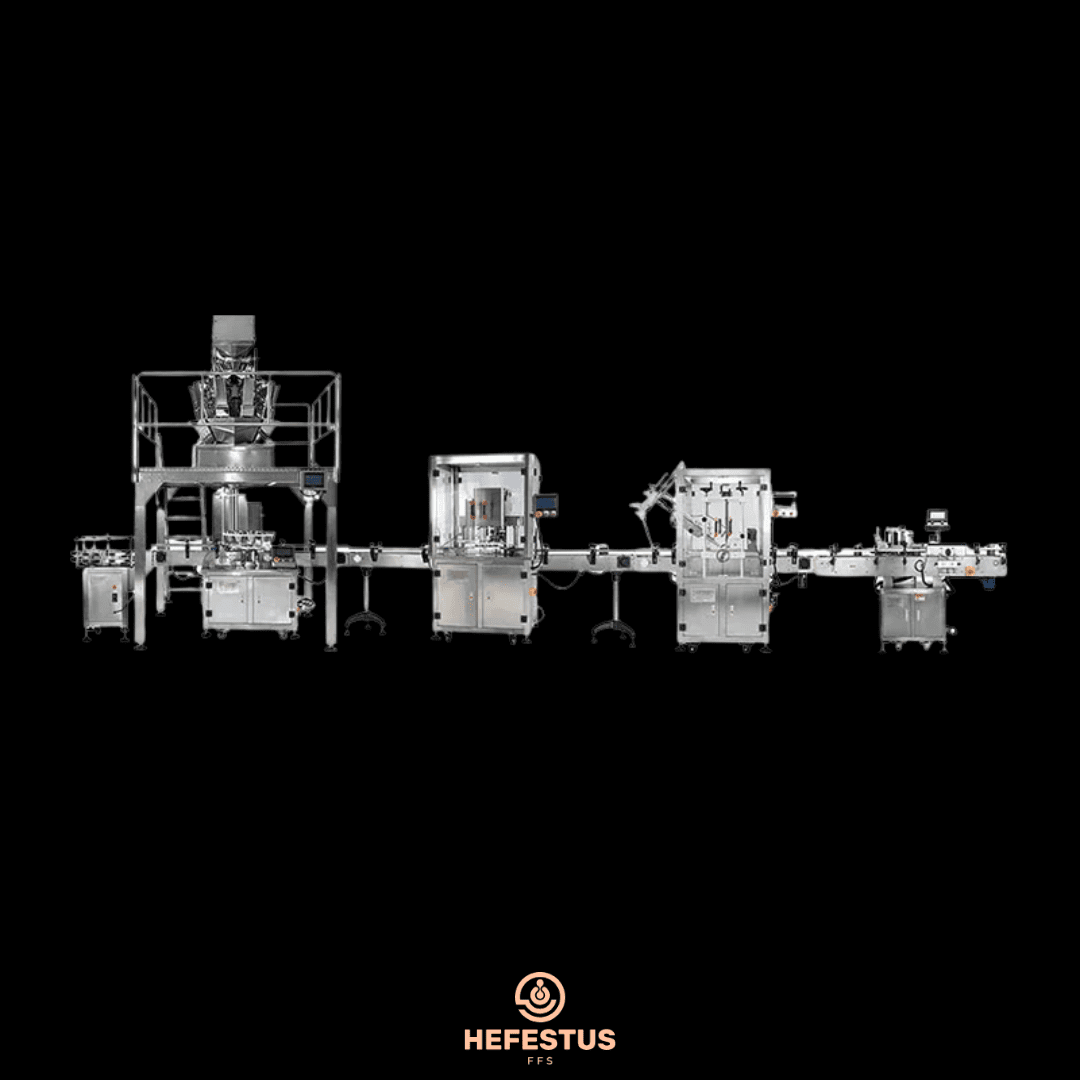

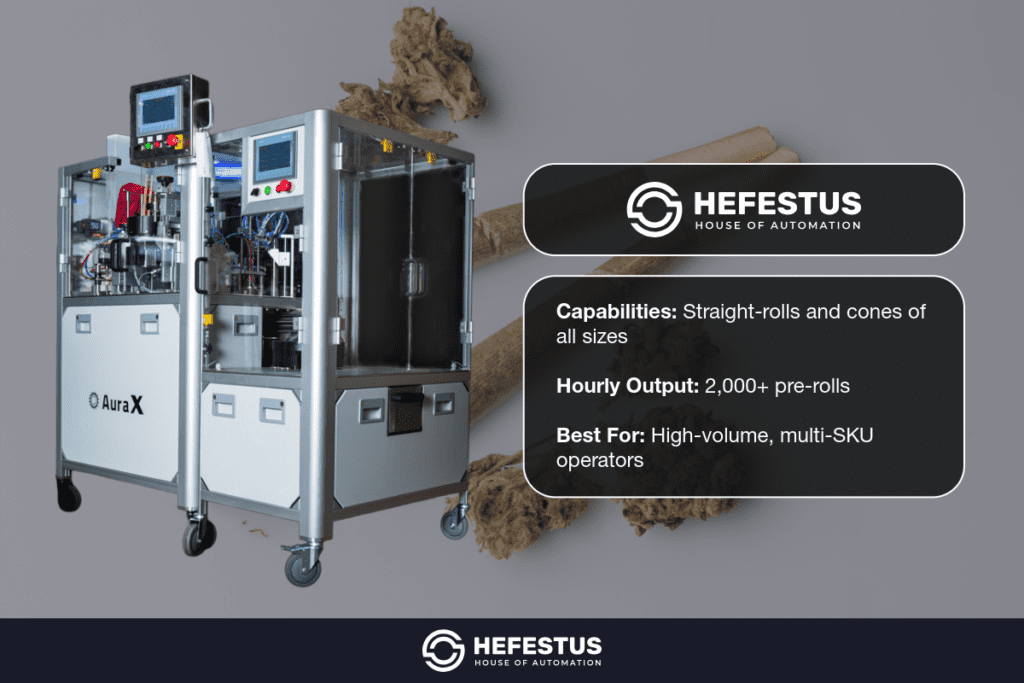

APEHEX vs. Hefestus AuraX

At a certain point, cone automation stops being the bottleneck and overall production efficiency takes its place.

The APEHEX is effective at standardizing cone output and reducing hands-on work, but it keeps production narrowly focused. Once your line starts juggling tighter timelines, larger runs, or more complex SKUs, the limits of a cone-only system become more noticeable.

The AuraX is built to address those broader pressures. Instead of optimizing one step of the process, it automates the full pre-roll workflow across formats and materials, allowing output, consistency, and product variety to scale together.

The practical difference shows up on the floor: fewer workarounds, fewer changeovers, and fewer moments where production slows because the equipment can’t keep up.

Quick Comparison

| Feature | APEHEX | Hefestus AuraX |

| Primary Use | Efficient cone filling for moderate-scale operations | End-to-end pre-roll automation for enterprise-level operations |

| Formats Supported | Cones and straight rolls | Cones and straight rolls |

| Typical Output | 1,200 pre-rolls per hour | 2,000 pre-rolls per hour |

| Typical Price | Price not publicly listed | ~$230,000 |

| Best Fit | Streamlining cone production | Scaling volume and variety |

Conclusion: Choosing the Right Pre-Roll System

The APEHEX does what it’s meant to do: it brings consistency to cone production and takes a lot of manual work off your plate. For many teams, that alone makes day-to-day production easier and more predictable.

But production needs don’t stay the same for long. As volumes grow or product lines expand, a cone-only system can start to feel like something you’re working around instead of with.

If you’re thinking about what comes next for your pre-roll line, the Hefestus team can help you map that out and show how the AuraX fits when full automation becomes the better move.

APEHEX Review: Frequently Asked Questions

If you’re considering the APEHEX, these are some of the most common questions operators ask before making a decision.

How much does the APEHEX cost?

APEHEX pricing isn’t publicly listed and varies based on configuration and purchasing options. It’s generally positioned below enterprise systems, with financing and leasing available to reduce upfront cost.

How many pre-rolls per hour can the APEHEX produce?

The APEHEX is rated for up to 1,100-1,200 pre-rolls per hour, depending on cone size and material. Throughput can vary based on setup, prep, and how dialed-in the machine is.

Does the APEHEX work with infused flower?

Yes, the APEHEX can run infused flower, but only within specific limits. Heavier or more complex infusions may require a system designed for higher infusion loads.

Is the APEHEX fully automated?

The APEHEX automates cone filling and finishing, but it still requires an operator for loading, material prep, and monitoring. It’s best described as automated cone production rather than full end-to-end automation.