Are Pre-Roll Machines Worth It? A Breakdown for Operators

As your pre-rolling operation grows, hand-rolling eventually becomes a bottleneck. Once you hit a certain volume, a pre-roll machine becomes the simplest way to increase efficiency while keeping labor costs under control.

But every operation is at a different stage – both in terms of the required production volume and the SKUS being produced. Accordingly, each machine on the market is built for different volumes, workflows, and product goals.

That’s why choosing the right system matters. If you’re exploring a pre-roll machine for your business, our guide breaks down what to look for when comparing options — and how to choose the right system for your operation.

How to Know What Kind of Pre-Roll Machine You Need

In any pre-roll operation, your production variables determine which features matter most in a machine.

These variables include throughput requirements, labor availability and cost, product mix or SKU variety, quality standards, and workflow or changeover demands – here’s a bit about each:

- Throughput & volume: Operations producing 2,000+ pre-rolls per hour should consider fully automated or enterprise options, while operations under 1,000 per hour can often meet demand with semi-automatic options.

- Labor availability & labor cost: Consider the cost savings from the pre-roll machine and the training required. If you experience high turnover, a more intuitive or easier-to-train model can help keep workflows moving and protect your per-unit cost.

- Product mix & SKUs: If your operation runs multiple cone sizes and premium lines with infused SKUs, maintaining quality and efficiency requires automated machines that can handle both infusion and a range of sizes.

- Quality standards: If higher reject rates are acceptable, lower-tier systems may be sufficient. However, if you’re looking for the highest standards and most consistent results, higher-tier automation is the better choice.

- Workflow & changeover demands: Consider how easily the equipment can change strains, how often it needs to be cleaned, and the level of operator skill required to minimize downtime.

Finally, your decision will depend on upfront cost and available capital. But equipment price alone doesn’t tell the full story.

Consider the manufacturer’s service and support offerings, and the per-unit cost impact of choosing between semi-automatic, fully-automated, and enterprise systems.

When Semi-Automatic Machines Make Sense

Semi-automatic machines are well-suited for lower- to mid-volume operations producing hundreds to a few thousand pre-rolls per day. This is often the stage where you’re not yet ready for full automation but need to fulfill demand more efficiently.

Most operations will upgrade to semi-automatic workflows when they have the labor to run the machines and want to reduce worker fatigue while improving consistency.

The systems also have a faster learning curve than fully automated systems, making them easier to integrate into existing workflows.

Because semi-automatic machines don’t automate the entire process end to end, you’ll still need hands-on labor to complete finishing steps like closing, quality checks, and weight verification.

With a lower upfront cost, semi-automatic machines make sense for growing operators who need more reliable workflows without committing to full automation.

When Fully Automated Systems Become the Better Investment

There’s a point where increasing daily volume becomes unsustainable for a small team. Once you reach that threshold, a fully automated system becomes the better investment, helping stabilize throughput while reducing labor dependency and cost.

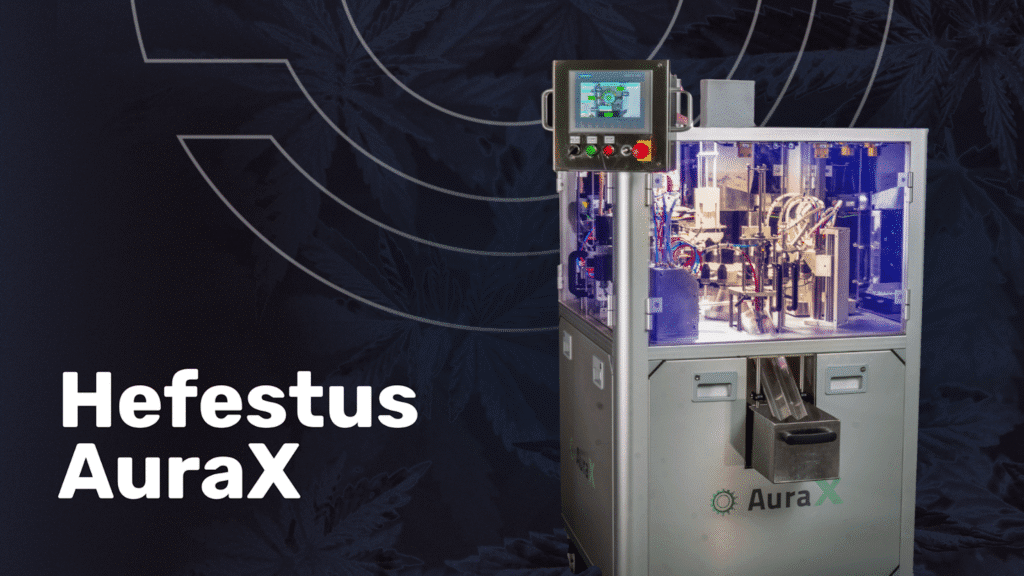

Semi-automatic machines can increase output, but as demand grows, so does the number of stations and operators required to keep up. As labor costs rise, this is where fully automated systems like the Hefestus AuraX make sense – one machine can replace multiple workers while maintaining consistent production.

With this upgrade, you’ll gain tighter quality assurance that reduces human error and reject rates, improving overall profitability. Consistent weight and density support stronger customer loyalty and retention, while reduced waste delivers savings beyond labor alone.

Fully automated workflows also reduce variability between operators, supporting consistency and repeatable output for your brand and for any third-party brands you produce as a co-manufacturer or supplier.

Lastly, the future of cannabis is heading toward infused pre-rolls. To handle or offer these SKUs, full automation is best suited to the complexity of infusion, with less downtime than semi-automatic setups, allowing you to scale the product category more effectively.

When Enterprise Automation Delivers the Most Value

If you have the demand to produce tens of thousands of units per day, enterprise automation is the right fit. This tier of equipment is designed to manage large SKU families with ease, from multiple sizes and formats to straight-rolls, cones, blunts, and infused products.

Rather than simply streamlining your workflow from start to finish, enterprise automation improves each step by prioritizing pack density, accurate and repeatable output, and the ability to run fresh, sticky, high-moisture flower without constant troubleshooting.

All while reducing reject rates and improving consistency across SKUs. At this level, the initial investment pays for itself quickly through increased volume and lower labor costs.

These systems have the greatest impact on labor efficiency, as a single operator can typically manage high throughput with minimal intervention. This reduces both oversight and the complexity of training large teams.

With engineered reliability that enables faster changeovers and strong manufacturer service and support, enterprise automation directly protects margins as scale increases. Some manufacturers even offer SOP development to better support your exact operations.

Overall, this is the only equipment tier that can support rapid growth with predictable, consistent output and premium SKU capabilities at true commercial scale.

Case Study: How The Fully Automated AuraX Pre-Roll Machine Helped Seed & Smith 10x Production

Seing a real-world case study can help to illustrate the ROI that a fully automated pre-roll machine can produce for your business.

One of our customers, Seed & Smith, a vertically-integrated facility in Colorado, came us to us wanting to automate their pre-roll production.

Before this move, they were producing between 1,200 and 1,500 pre-rolls per day using a fully manual process. Good volume, but it required a full team to implement.

After investing in the AuraX, though, they were able to 10x their production.

Michael Lempert, President of Seed & Smith explains:

“The major step came when we decided to move to a Hefestus machine. Now with a few months under our belt running the machine with just a two-person crew, we’re seeing anywhere from 10,000 to 15,000 units a day, start to finish — from full nugs of flower all the way to finished pre-rolls in packaging. Easily a 10x improvement upon what we were able to do [earlier].”

Michael also adds, “we could probably improve that to 15 or 20x should we put a little more labor at it and shore up some of our inefficiencies that we’re running into internally.”

And because the AuraX fills and cuts cones based on the specifications given to it, Seed & Smith is able to produce all of their pre-roll sizes — which range from 0.5g to 1.5g — using just one cone size. They don’t need to stock multiple types of cones to produce different sizes of pre-roll.

Ultimately, your operation’s scaling process will look different from anyone else’s. You might go straight from manual rolling to enterprise-level automation (as Seed & Smith did), or you might graduate to a semi-automatic machine before moving up. Either way, investing in automation is definitely worth it if your business stands to make more revenue and profit by increasing pre-roll production.

Conclusion: Are Pre-Roll Machines Worth It?

So, are pre-roll machines worth it? For most operations, yes. From small craft producers to full-scale enterprise facilities, semi-automatic and fully automatic equipment is the solution to real production challenges.

The right system reduces labor costs, improves consistency and quality, and increases your operation’s volume to levels that hand-rolling just can’t keep up with.

What matters most is choosing equipment that fits where your operation is today and where it’s headed next. With Hefestus, you get reliable, scalable automation built to grow with you, trusted by the industry’s top brands.

Contact us today to speak with our team about implementing pre-roll automation for your business.

Are Pre-Roll Machines Worth It?: Frequently Asked Questions

Here are answers to the most frequently asked questions about the ROI of pre-roll machines.

What Are the Benefits of Using a Pre-Roll Machine?

The benefits of using a pre-roll machine include improved consistency, speed, and weight while reducing labor costs and waste. They can also standardize pack density and airflow, improving the customer experience while increasing throughput and quality control across every shift.

What Is the Best Pre-Roll Machine for Home Use?

The best pre-roll machine for home use will depend on your exact volume and budget; however, typically, simple manual or tabletop machines are usually sufficient. These options offer basic consistency and ease of use without the cost or footprint of commercial automation.

Is it Better to Roll by Hand or Use a Machine?

It’s better to use a machine when working in commercial settings with the volume or output demand; however, rolling by hand works for personal use or low volumes. Pre-roll machines remove variability in weight, density, and burn, which is difficult to maintain by hand at scale.

How Much Do Pre-Roll Machines Cost?

Pre-roll machine costs vary widely based on automation level, output capacity, and features. Manual machines may cost a few hundred dollars, while fully automated commercial systems can range from tens of thousands to six figures.