What is Roll Stock?

What is roll stock? It’s one of the most misused questions in packaging – and the confusion costs manufacturers real money. The term gets treated as a synonym for flexible packaging on a roll, when in reality it describes a manufacturing dependency, not a packaging format. Misunderstanding this leads to poor equipment choices, wasted film, and production lines that never reach their projected efficiency.

Before talking about benefits, materials, or machines, you need clarity. Not marketing clarity – operational clarity. This section establishes exactly what roll stock packaging is, what it is not, and why the distinction matters if throughput, cost control, and scalability actually matter to your business.

What Is Roll Stock Packaging?

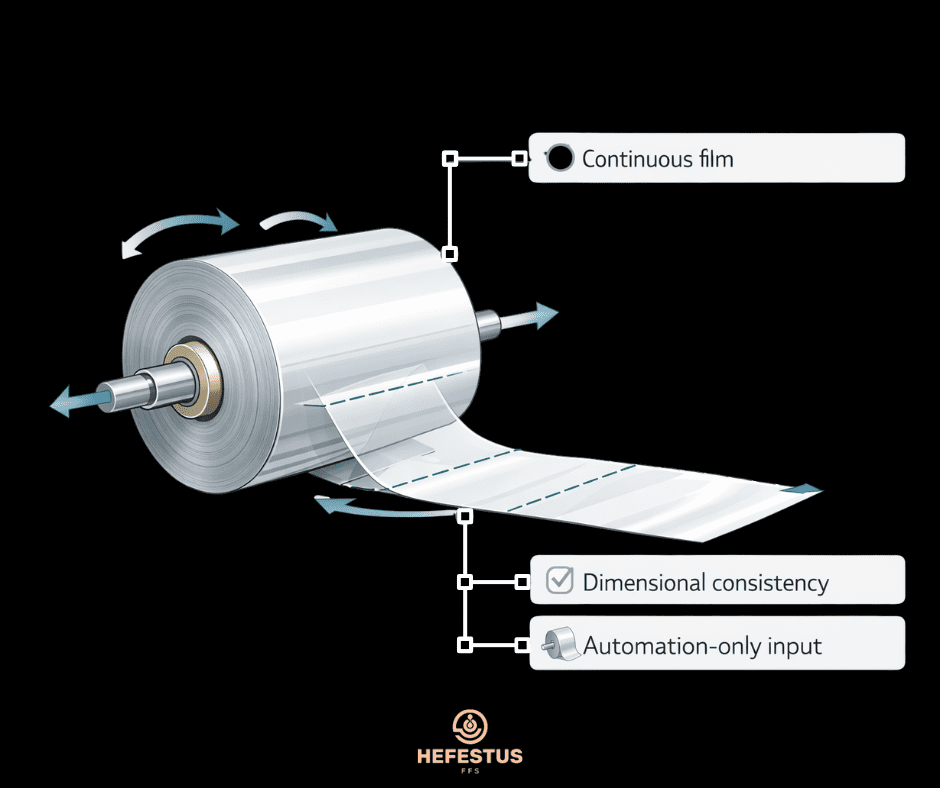

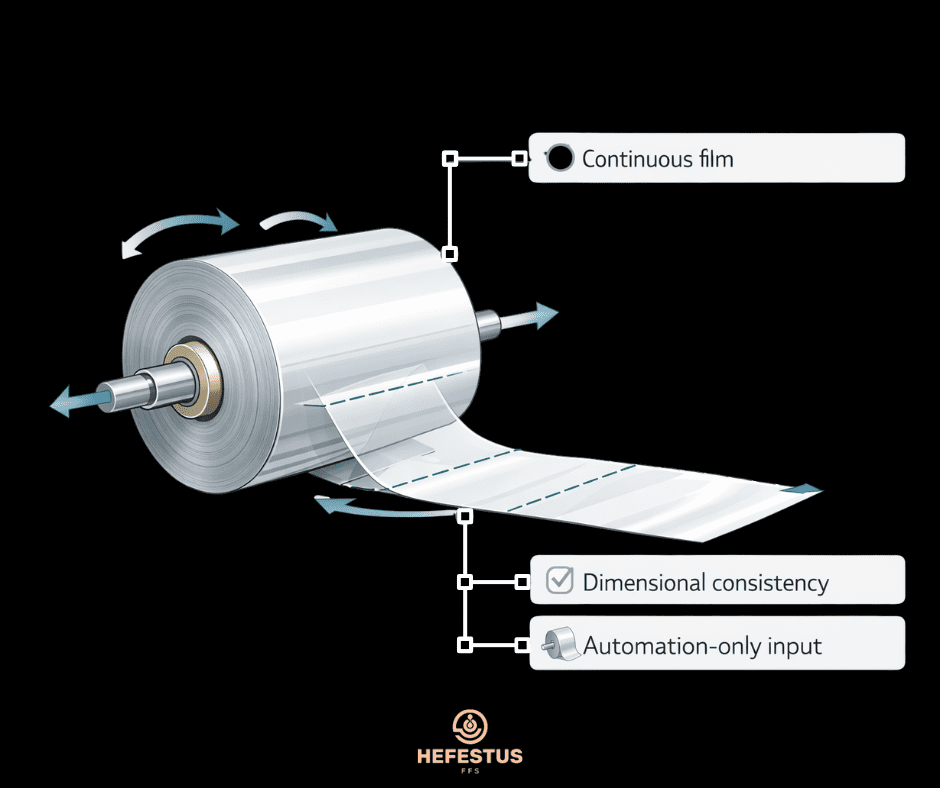

Roll stock packaging is flexible packaging film supplied on a continuous roll and designed to be formed, filled, and sealed on automated machinery.

That’s it. No hype. No adjectives.

What roll stock is not

- It is not pre-made bags or pouches

- It is not usable on its own

- It is not packaging until a machine forms it

If it isn’t run through automation, roll stock is just plastic on a core.

Why the term exists at all

The term roll stock exists because the material is inseparable from automation. It only has value when paired with form-fill-seal (FFS) systems. This distinction matters because many buyers confuse roll stock with “bags on a roll.” They are not the same thing.

Value add:

Roll stock describes a manufacturing input, not a finished package.

What “Roll Stock” Actually Means in Manufacturing

In manufacturing terms, roll stock means continuous flexible film wound on a cylindrical core. That definition matters because roll stock is engineered for motion, not storage. Every aspect of the material – from thickness tolerance to edge consistency – is designed to perform under constant movement.

Roll stock is engineered to maintain consistent tension, move predictably through automated systems, and remain dimensionally stable across long production runs. It assumes in-line forming by default and is manufactured with the expectation that it will be shaped, sealed, and cut at speed – often hundreds of times per minute.

Designed only for automated forming

Roll stock is not a flexible “option” material. It is made to be unwound, shaped, sealed, and cut in one continuous process. The material itself is optimized for automation, not manual handling or post-processing.

This is why roll stock only makes sense inside automated packaging environments.

Why roll stock without FFS is useless

Without form-fill-seal (FFS) equipment, roll stock has no functional value. You cannot shape it into a package, you cannot seal it reliably, and you cannot control tolerances or repeatability. The material is incomplete by design.

Buying roll stock without matching machinery is like buying engine fuel without an engine. The material only becomes packaging after the machine does its job.

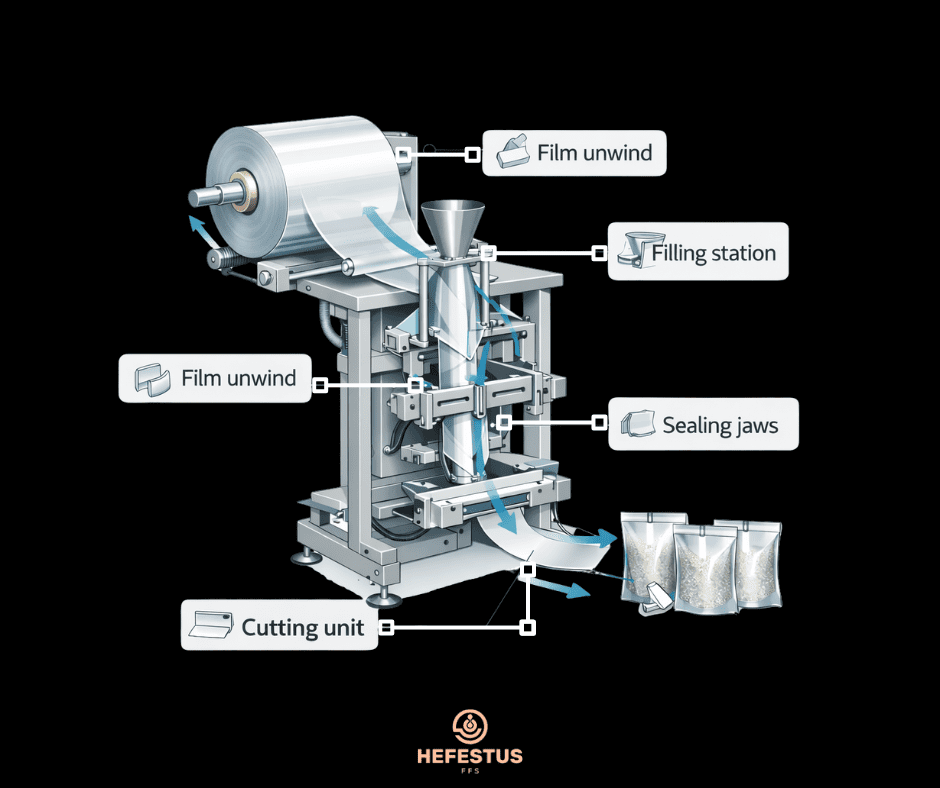

How Roll Stock Packaging Works (FFS Explained)

The Form-Fill-Seal Dependency (Critical)

Roll stock only works because of form-fill-seal (FFS) systems.

There is no “manual roll stock packaging.”

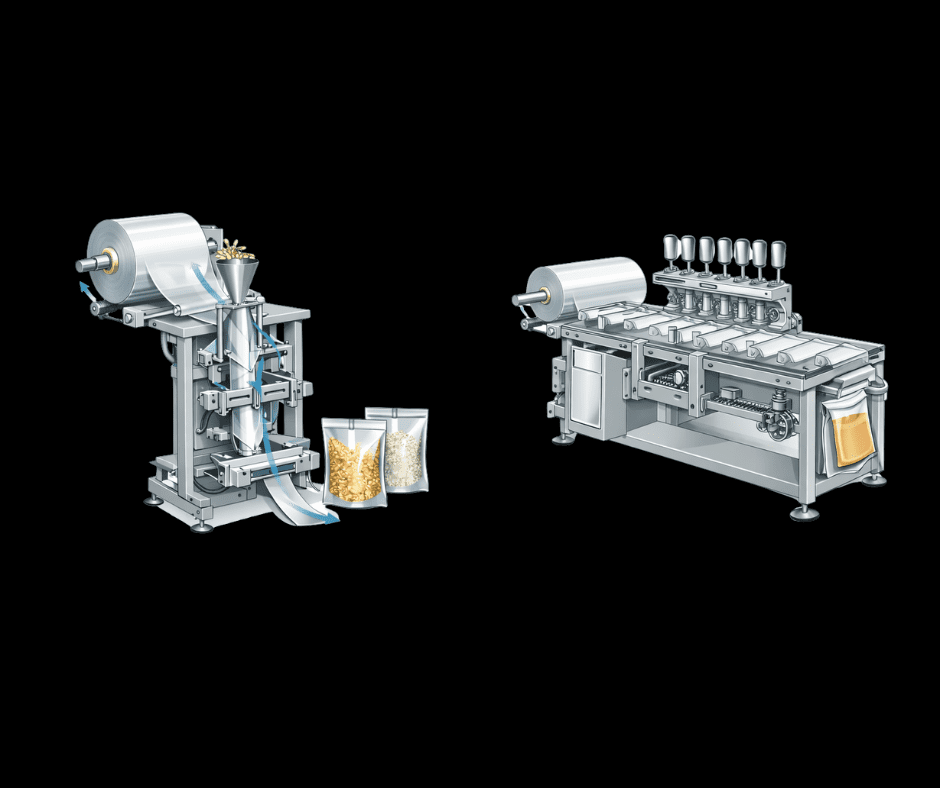

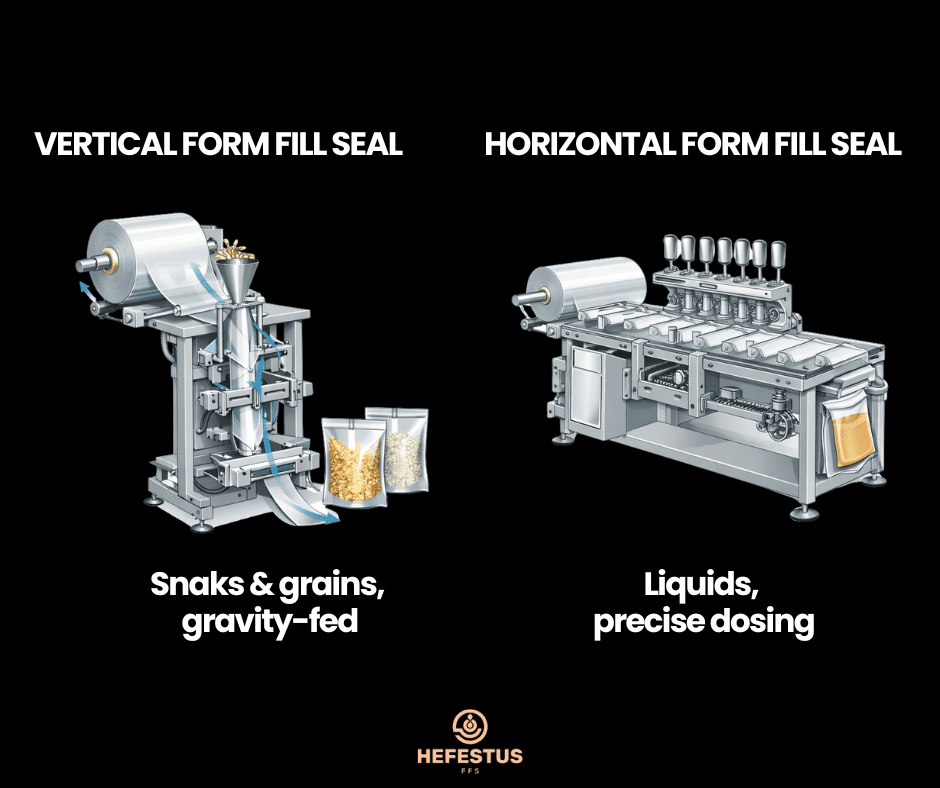

Vertical vs. Horizontal (use-case framing)

- Vertical FFS (VFFS):

- Best for gravity-fed products like snacks, grains, powders, frozen foods

- Prioritizes speed and footprint efficiency

- Horizontal FFS (HFFS):

- Best for sachets, liquids, gels, medical products

- Prioritizes dosing precision and seal control

The choice isn’t technical – it’s operational.

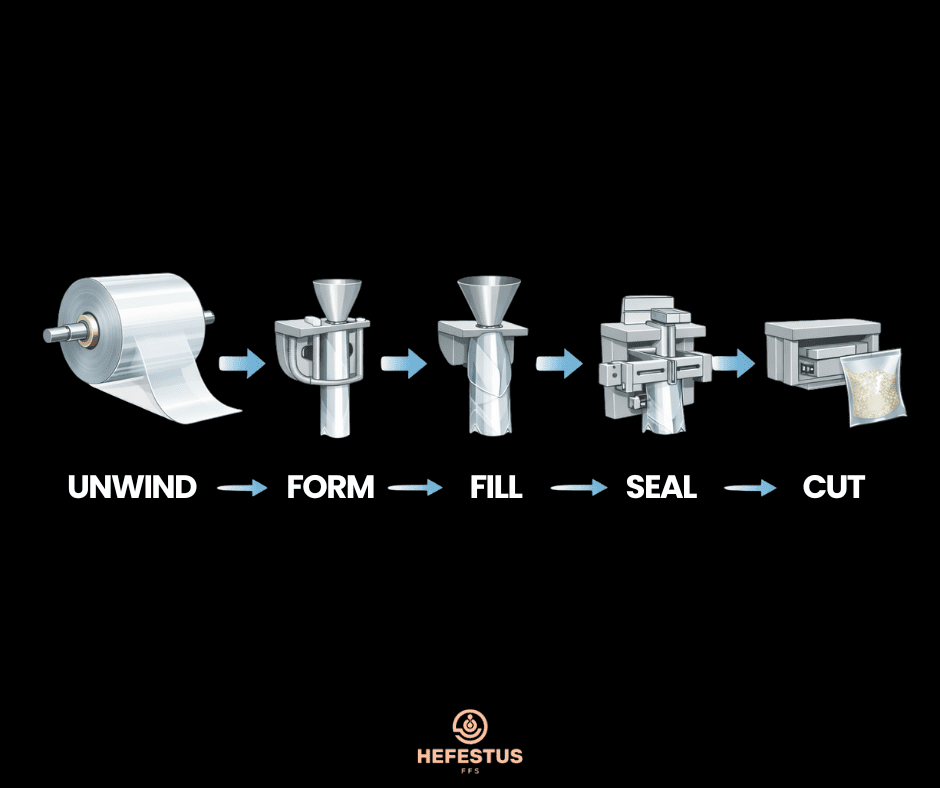

Step-by-Step Production Flow

Roll stock packaging follows a fixed, sequential process. Each step is mechanically simple, but small deviations compound quickly at production speed.

- Unwind – The film feeds from the roll under controlled tension.

Tension stability is critical here; uneven unwind pressure can distort the film before it ever reaches the forming section. - Form – The flat film is shaped into a tube, pouch, or cavity depending on the machine type.

This step establishes the package geometry and determines how consistently downstream seals will perform. - Fill – Product is dispensed into the newly formed package.

Accuracy depends on synchronization between dosing systems and film movement, especially for powders, granules, and liquids. - Seal – Heat, pressure, and dwell time close the package.

This is the most failure-prone stage, as seal quality is directly affected by film structure, temperature control, and line speed. - Cut – The finished package is separated and discharged.

Inconsistent cutting can indicate upstream tension or registration problems.

Where failures usually happen

Most roll stock problems don’t come from a single defect – they come from small mismatches amplified at speed:

- Seal integrity issues caused by heat and pressure mismatches or insufficient dwell time

- Film tension drift, often due to improper unwind control or inconsistent roll quality

- Poor material–machine compatibility, where the film structure cannot tolerate the machine’s operating window

This is where real money is lost – through scrap, downtime, and rework rather than visible breakdowns.

Roll Stock Packaging Materials (What Actually Matters)

Common Film Layers (and why single-layer films fail)

Most roll stock films are multi-layer laminations, not single sheets. Each layer exists to solve a specific problem that single-layer films cannot handle simultaneously – especially at production speed.

Common layers include:

- PE (Polyethylene) – provides sealability and flexibility; this is the layer that actually closes the package

- PP (Polypropylene) – adds stiffness and clarity, improving machinability and shelf appearance

- PET (Polyethylene Terephthalate) – delivers tensile strength and a stable print surface for graphics

- Aluminum foil – creates a near-absolute barrier to oxygen and light, used when shelf life is critical

- Metallized films – offer improved barrier performance with less material than foil, balancing cost and protection

Single-layer films fail because they cannot balance sealability, strength, and barrier performance at speed. What works in a lab often breaks down on a production line.

Inner vs. Outer Layer Roles

Layer placement matters as much as material choice. Each side of the laminate serves a distinct function.

- Inner layer: responsible for sealing and direct product contact; errors here lead to leaks and contamination

- Outer layer: provides mechanical protection, print quality, and structural stability during handling and transport

Confusing these roles – or specifying the wrong sealant layer – leads directly to seal failure, scrap, and downtime.

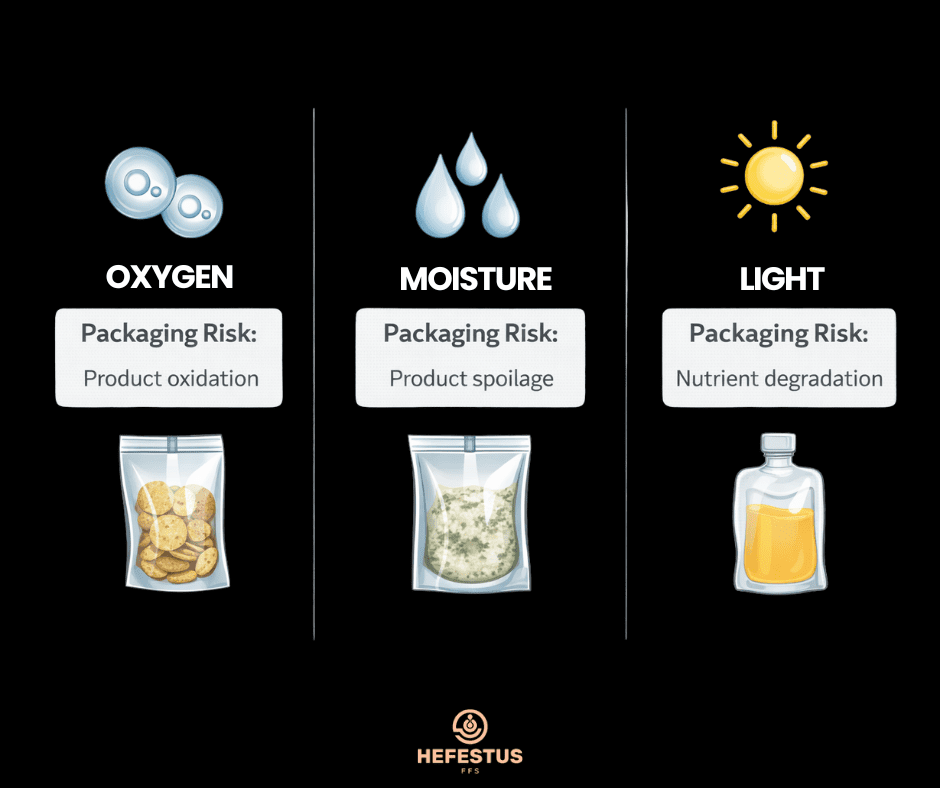

Barrier Properties That Actually Affect Shelf Life

Barrier performance is often oversimplified. In reality, different products fail in different ways.

- Oxygen, moisture, and light are not interchangeable threats

- The phrase “high barrier” is meaningless without context

For example:

- A product that is oxygen-sensitive is not necessarily moisture-sensitive

- Aluminum foil may solve oxygen ingress but complicates recyclability and increases cost

- Metallized structures improve barrier but reduce tolerance to heat variation

Competitors list materials. Manufacturers live with the consequences of how those materials behave at scale.

Advantages of Roll Stock Packaging (With Constraints)

Roll stock packaging delivers real advantages – but only when the operating conditions support it. These benefits are not universal; they emerge when volume, consistency, and automation discipline are present.

Where Roll Stock Wins (Objectively)

- Cost per unit drops at stable, high volumes

Once production runs are long and repeatable, roll stock reduces per-unit material and labor costs by forming packages in-line with minimal waste. - Speed ceiling far exceeds manual or semi-automatic packaging

Automated form-fill-seal lines can run continuously at rates that manual or pre-made pouch systems cannot sustain without adding labor. - Storage efficiency improves logistics economics

Rolls of film occupy significantly less warehouse space than pallets of pre-formed bags, reducing storage, handling, and transport complexity.

Roll stock rewards repeatability. The more predictable the operation, the more these advantages compound.

Where Roll Stock Loses (They Avoid This)

- High capital cost

Form-fill-seal equipment requires a meaningful upfront investment, which can be difficult to justify without committed volume. - Complex changeovers

Switching SKUs, formats, or film structures increases downtime and setup scrap compared to pre-formed packaging. - Limited package geometry

Roll stock excels at standardized shapes but struggles with highly complex or rigid package designs. - Seal risk when film and machine are mismatched

Incompatible materials, incorrect sealant layers, or narrow sealing windows can cause leaks, rejects, and line stoppages at speed.

Admitting these limitations is a trust signal, not a weakness. Roll stock is powerful – but only when its constraints are respected.

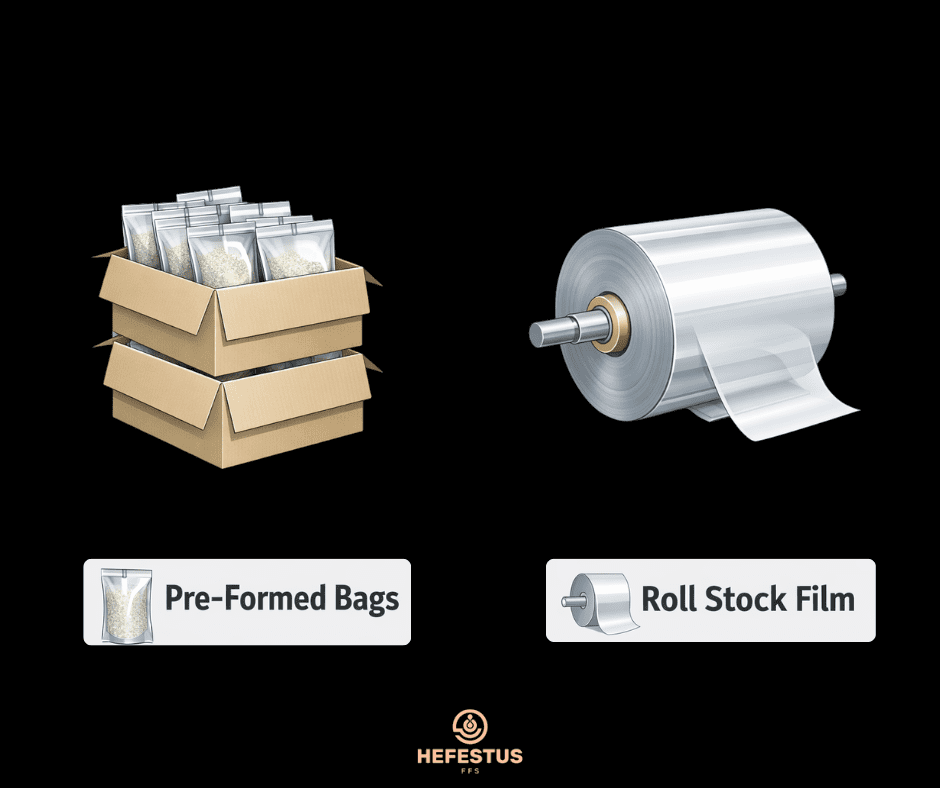

Roll Stock vs Pre-Formed Packaging

Choosing between roll stock and pre-formed packaging is not about which is “better.” It’s about where your operation sits today and how stable it will be tomorrow.

Cost Comparison (Upfront vs Long-Term)

- Roll stock: higher upfront equipment cost, lower unit cost at scale

Form-fill-seal machinery requires a significant capital investment, but once volume is consistent, the cost per package drops due to reduced labor, in-line forming, and lower material waste per unit. - Pre-formed packaging: low equipment cost, higher per-unit cost

Pre-made bags and pouches require minimal machinery, making them attractive early on. However, the per-unit cost remains higher because you are paying for conversion, storage, and handling upfront.

Key reality:

ROI flips in favor of roll stock only when volume and consistency increase together. Without both, the economics do not work.

Operational Flexibility vs Efficiency

- Roll stock favors long runs and low SKU counts

Efficiency improves when the same format runs repeatedly with minimal changeovers. Frequent SKU changes increase downtime, scrap, and setup complexity. - Pre-formed packaging favors variety and speed of change

Switching between formats or products is faster because the package already exists. This flexibility is valuable for short runs, seasonal products, and fast iteration.

In short:

- Roll stock optimizes efficiency through repetition

- Pre-formed packaging optimizes flexibility through simplicity

This tradeoff – not price alone – should drive the decision.

| Production Volume | SKU Variety | Best Choice |

| Low | High | Pre-formed |

| Medium | Medium | Depends |

| High | Low | Roll stock |

What Products Actually Make Sense for Roll Stock

Roll stock packaging performs best when the product, volume, and process requirements align. It is not universally suitable, but in the right applications it delivers clear advantages.

- Food: dry goods, snacks, and frozen foods

These products benefit from roll stock’s speed, repeatability, and barrier control, especially when shelf life and throughput matter more than frequent format changes. - Liquids & powders: with controlled sealing and dosing

Roll stock works well when filling accuracy and seal integrity are tightly managed. Poor synchronization between dosing and sealing quickly erodes efficiency. - Pharma / medical: when sterilization and compliance are required

Roll stock supports aseptic processing and validation workflows when regulatory requirements (e.g., FDA) demand controlled, repeatable packaging conditions.

Where roll stock is a bad idea

Some conditions actively work against roll stock economics and reliability.

- Frequent SKU changes

Changeovers increase downtime, setup scrap, and operator intervention. - Small, unstable volumes

Without consistent run lengths, setup losses outweigh material savings. - Products requiring complex 3D shapes

Roll stock excels at standardized geometries, not rigid or highly contoured formats.

In these cases, pre-formed packaging or outsourcing is often the smarter move.

Common Roll Stock Packaging Mistakes (Costly Ones)

Most roll stock failures don’t come from equipment breakdowns – they come from planning errors.

- Buying film before machine specifications are finalized

Film structure must match sealing systems, temperatures, and line speed. - Ignoring seal validation

Seal failures rarely show up immediately but cause scrap, recalls, and downtime later. - Over-engineering barrier layers

More layers increase cost and narrow the machine’s operating window without always improving shelf life. - Assuming any FFS machine will work

Machine design, control precision, and tolerance ranges matter more than brand names.

These mistakes compound fast because they affect every package produced.

How to Decide If Roll Stock Is Right for Your Business

Before committing to roll stock, you should be able to answer the following clearly:

- What is your monthly unit volume?

- How sensitive is the product to oxygen, moisture, or light?

- How often do SKUs or formats change?

- Is sufficient floor space available for automated equipment?

- Is labor cost or availability a real constraint?

If you can’t answer these, roll stock will hurt you – through scrap, downtime, or capital that never pays back.

Frequently Asked Questions

Is roll stock only for high-volume production?

Mostly, yes. Below scale, setup waste dominates savings.

How much does roll stock packaging actually cost?

Material is cheaper per unit; equipment is not. Economics depend on volume.

Can small brands use roll stock without owning machines?

Yes – via co-packers who already run FFS lines.

What causes roll stock seal failures?

Mismatch between film structure, heat, pressure, and dwell time.

How long does rollstock film last in storage?

Typically 6–12 months if stored correctly; humidity and temperature matter.

Final Takeaway

So, what is roll stock, really?

Roll stock is not better packaging by default. It is a manufacturing strategy that only works when the operation around it is designed for consistency, automation, and scale. The material itself is unfinished by design – it only becomes packaging when a form-fill-seal system does its job, repeatedly and precisely.

In the right context, roll stock packaging lowers cost per unit, increases throughput, and reduces labor dependence. It rewards stable volumes, disciplined processes, and well-matched film and machine specifications. When those conditions exist, roll stock becomes a powerful efficiency lever.

In the wrong context, it does the opposite. High capital costs, frequent changeovers, poor seal performance, or unstable demand quickly turn roll stock into a silent drain on cash. Scrap increases, downtime multiplies, and the promised efficiency never materializes.

That’s why the real question isn’t whether roll stock is advanced or popular. The question is whether your operation is ready for what roll stock demands. If you treat it as “just another packaging option,” it will punish you. If you treat it as a system-level manufacturing decision, it can scale your business efficiently and predictably.

Understanding what roll stock is – and just as importantly, when it is the wrong choice – is what separates efficient packaging lines from expensive ones.