VFFS vs HFFS

Choosing between VFFS vs HFFS isn’t a technical footnote—it’s a capital decision that affects throughput, operating costs, floor space, packaging quality, and long-term scalability. Pick wrong, and you don’t just lose efficiency—you lock yourself into years of avoidable cost and complexity.

In reality, this decision is about:

- How your product behaves under motion

- How your production line is laid out

- How hygiene and sanitation are managed

- How easily the line can scale or adapt later

Choose the wrong system, and you don’t just lose efficiency. You lock yourself into:

- Inefficient automation architectures

- Chronic scrap and seal failures

- Costly line redesigns when volumes or SKUs change

This guide cuts through marketing noise and shallow comparisons. You’ll learn how vertical vs horizontal form fill seal machines really differ, where each shines, where they fail, and how to choose with confidence—especially for food packaging, where margins and compliance leave little room for error.

What Is a Form Fill Seal (FFS) Machine?

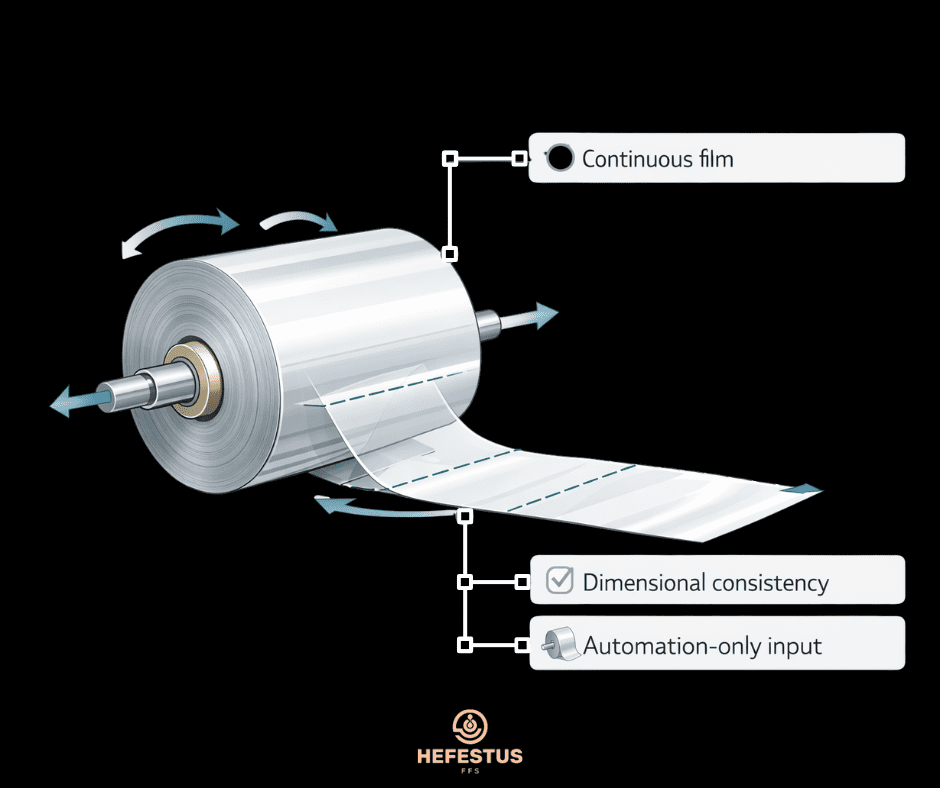

A form fill seal machine creates packages from a flat roll of flexible film, fills them with product, and seals them—all in one continuous operation. This eliminates the need for pre-made bags, reducing material costs and improving efficiency.

There are two dominant configurations:

- Vertical Form Fill Seal (VFFS) machines

- Horizontal Form Fill Seal (HFFS) machines (often called flow wrappers)

Both automate packaging—but they do it in fundamentally different ways, with very different implications for cost, speed, and product compatibility.

VFFS vs HFFS — The Core Mechanical Difference

The fundamental distinction between horizontal vs vertical form fill seal machines lies in how products move through the packaging cycle and how gravity, motion, and control are applied during forming, filling, and sealing. While both machine types perform the same core function, their mechanical orientation creates very different outcomes in automation efficiency, hygiene control, and product handling.

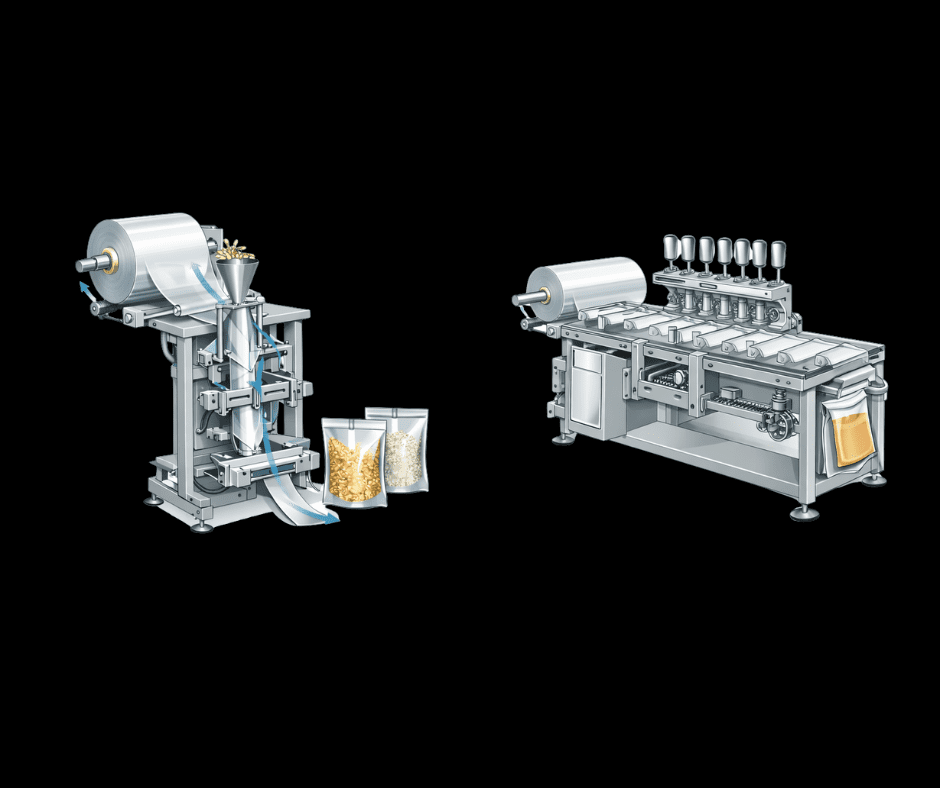

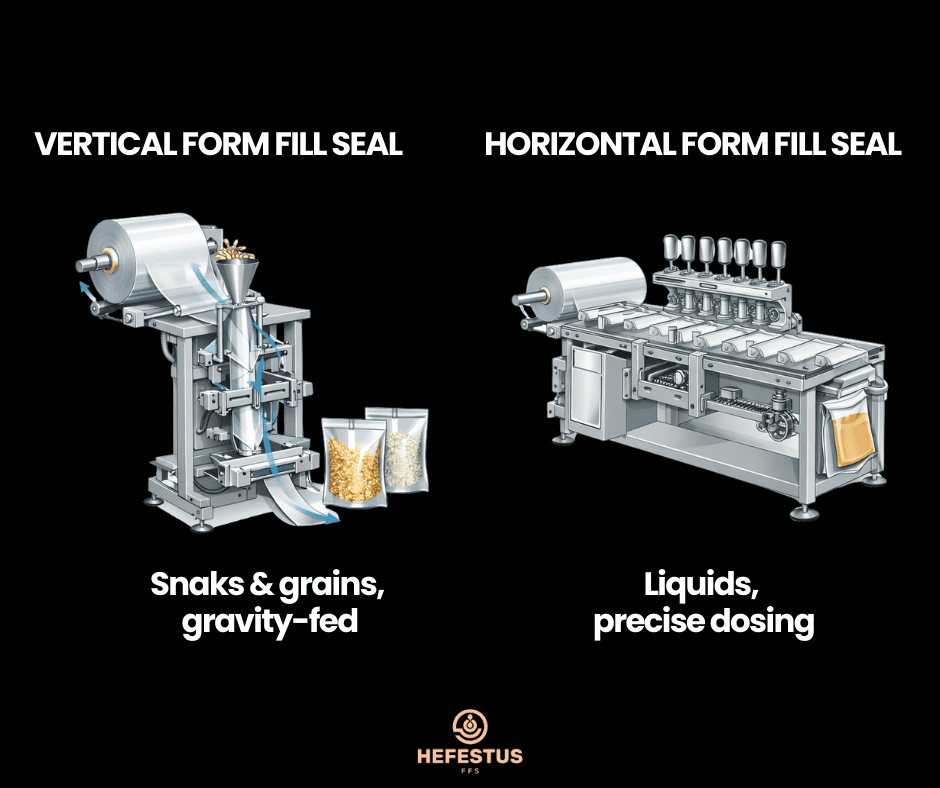

Vertical Form Fill Seal (VFFS) Machines

Vertical form fill seal (VFFS) machines operate using a gravity-driven vertical cycle. Packaging film is pulled downward over a forming tube, where it is shaped into a continuous tube. The bottom of the tube is sealed to form the base of the bag, product is dispensed from above, and the top seal is applied—simultaneously creating the bottom seal of the next package in the sequence.

This vertical, continuous motion is what defines VFFS systems. Because filling relies primarily on gravity, VFFS machines are particularly well suited for products that flow naturally, including powders, granules, liquids, and semi-free-flowing or sticky materials. The simplicity of this vertical cycle also means fewer moving parts, which typically translates into lower maintenance requirements, reduced mechanical wear, and easier day-to-day operation.

Another defining advantage of VFFS machines is their compact vertical footprint. By stacking forming, filling, and sealing operations vertically, VFFS systems conserve valuable floor space—an important consideration in food production facilities where layout density, sanitation zoning, and future expansion must all coexist.

However, this same simplicity introduces limitations. Because the product drops vertically into the package, VFFS systems can struggle with items that are sensitive to impact, inconsistent in flow, or prone to splashing, foaming, or seal contamination. As a result, gravity-driven filling is both VFFS’s greatest strength and its most significant constraint, depending on product behavior.

Common VFFS packaging formats

- Pillow bags

- Gusseted bags

- Quad-seal bags

- Sachets and stick packs (with appropriate tooling)

Typical use cases: coffee, rice, sugar, flour, spices, protein powders, candies, snacks, sauces, detergents.

Horizontal Form Fill Seal (HFFS) Machines

Horizontal form fill seal (HFFS) machines rely on controlled horizontal handling rather than gravity-driven filling. In these systems, products travel along a conveyor belt while packaging film is wrapped around them horizontally. The film is sealed longitudinally and transversely across multiple stations, after which individual packages are cut and discharged from the line.

This horizontal architecture is what allows HFFS machines to trade compactness for precision, flexibility, and control. Instead of relying on a vertical drop, the product remains supported throughout the packaging process, making HFFS systems particularly effective for items that are fragile, irregularly shaped, or sensitive to impact.

From a mechanical standpoint, HFFS machines are defined by conveyor-based product control, horizontal pouch formation, and multi-station filling, sealing, and cooling zones. These stations can be independently optimized, allowing greater control over seal integrity, cooling time, and package presentation—especially at higher speeds.

How HFFS Machines Work (and Why Conveyors Win on Speed)

In a horizontal form fill seal system, products are precisely spaced and transported along a conveyor belt. Packaging film is drawn from rollstock, wrapped around each product, sealed along its length, and then sealed and cut across the ends to form individual packages. Because the product remains continuously supported during this process, sealing operations can occur at multiple stages without destabilizing the contents.

This conveyor-based handling is the key reason HFFS machines achieve such high throughput for uniform products. Servo-driven systems allow tight synchronization between product movement, film feed, and sealing jaws, enabling very high packaging speeds without sacrificing seal consistency or package appearance.

HFFS systems also excel in applications where packaging complexity matters. They readily support advanced formats such as zippers, spouts, trays, cartons, and other hybrid packaging designs that are difficult—or impractical—to execute on vertical systems.

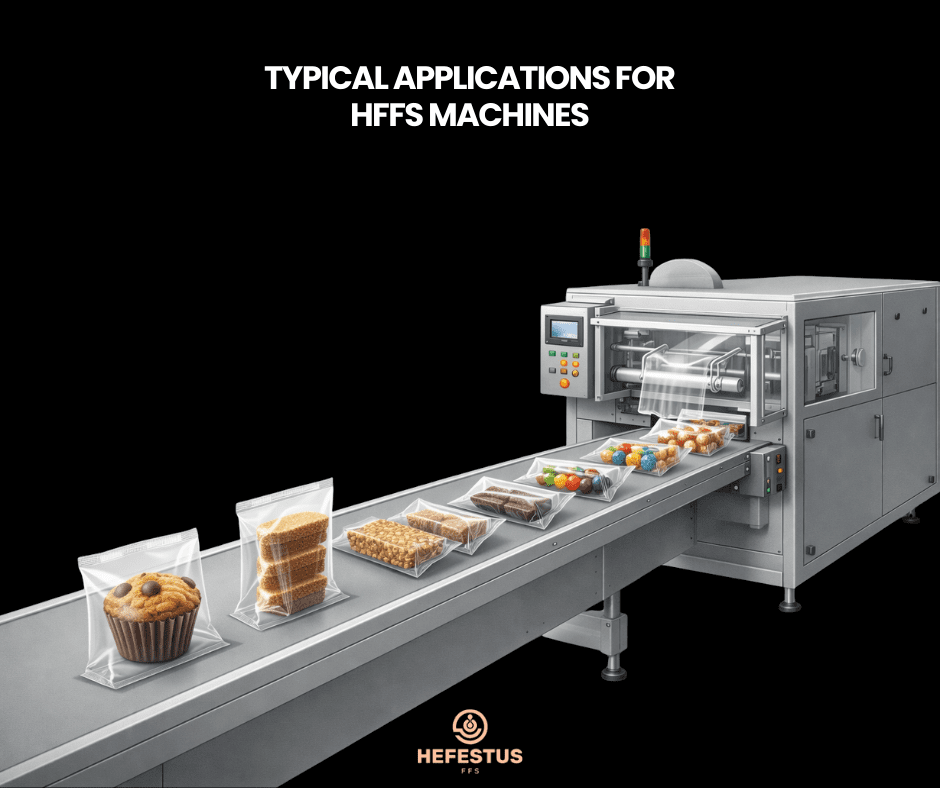

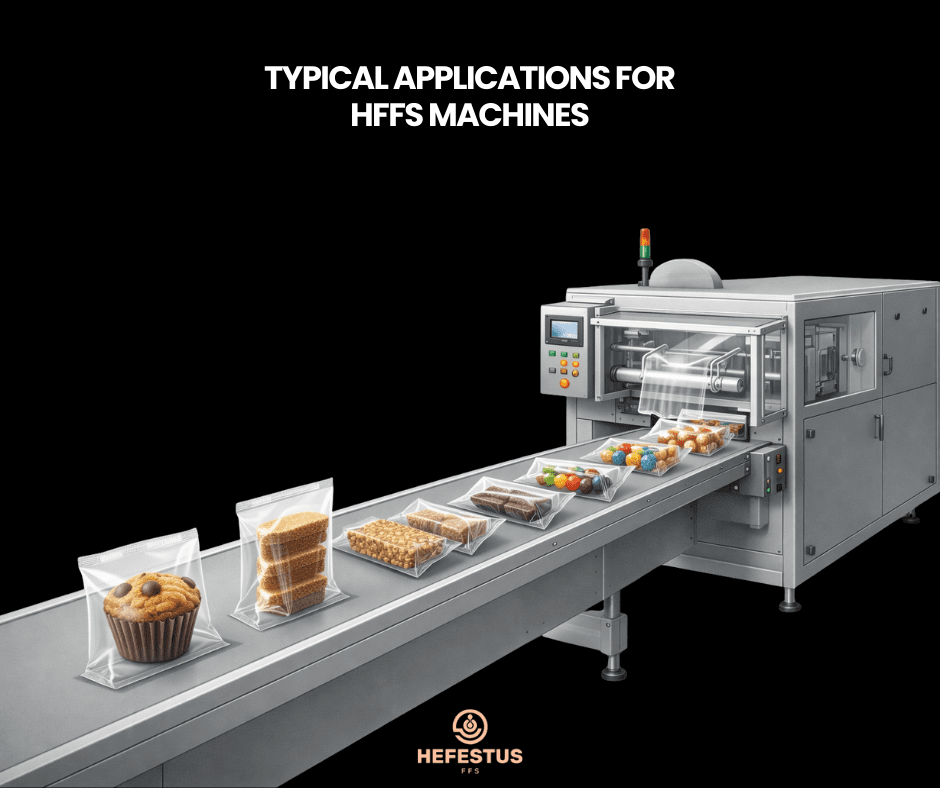

Common HFFS applications

- Bakery products (cakes, muffins, biscuits)

- Cereal and protein bars

- Confectionery

- Medical devices and non-food items

- Bundled or multi-pack products

| Factor | VFFS | HFFS |

| Orientation | Vertical (gravity-fed) | Horizontal (conveyor-fed) |

| Best for | Powders, granules, liquids | Solid, discrete, fragile items |

| Typical Speed | ~50–70 bags/min (single lane) | 200–400+ bags/min (product-dependent) |

| Footprint | Compact | Larger |

| CapEx | Lower entry cost | Higher initial investment |

| Packaging Styles | Pillow, gusseted, quad-seal | Flow wraps, pouches, cartons, zip/nozzle bags |

VFFS vs HFFS for Food Packaging: What Actually Decides the Winner

When comparing VFFS vs HFFS for food, the decision usually comes down to product behavior, not just speed.

Choose VFFS if your food product is:

- Powdery, granular, liquid, or sticky

- Difficult to handle manually

- Sensitive to leakage or contamination

- Produced in moderate-to-high volumes where cost per pack matters

Choose HFFS if your food product is:

- A single solid item (or tightly controlled portions)

- Fragile or easily deformed

- Highly brand-driven, requiring premium presentation

- Produced at very high volumes where speed offsets higher CapEx

Handling Viscous, Sticky, or Particulate Foods

For many food producers, products don’t fall cleanly into “liquid” or “solid” categories. Real-world food applications often involve complex consistencies such as sauces, soups, dairy products, and dips—materials that behave unpredictably under motion, pressure, and speed. These hybrid products are where the VFFS vs HFFS decision becomes most critical, because small handling errors quickly translate into scrap, downtime, or food safety risks.

In vertical form fill seal (VFFS) systems, these products introduce several inherent challenges. Because filling relies on a vertical drop, viscous or particulate foods are more prone to splashing and foaming as they enter the package, especially at higher speeds. Over time, this can lead to phase separation in emulsified products, inconsistent fill weights, and—most critically—product creeping into the seal area. Seal contamination not only increases scrap rates but also forces more frequent sanitation cycles and unplanned downtime.

Horizontal form fill seal (HFFS) systems mitigate many of these risks by fundamentally changing how the product is handled during filling. Instead of relying on gravity alone, HFFS machines support the product throughout the packaging process, reducing uncontrolled vertical movement and limiting impact forces. This controlled horizontal handling allows for more stable, metered dosing, which is particularly valuable for sticky, viscous, or multi-phase foods that require consistent distribution within the package.

The result is greater fill stability, cleaner seals, and more predictable output—especially in high-speed food automation environments. This is why horizontal handling often stabilizes fills for complex food products, even when gravity-fed systems appear simpler or more cost-effective on paper. In practice, the reduction in seal failures, sanitation interruptions, and product variability frequently outweighs the added mechanical complexity of horizontal systems.

Speed & Throughput: The Most Misunderstood Metric

Manufacturers love quoting maximum speeds—but speed specs alone are meaningless without context.

- HFFS machines can reach 300–400 bags per minute, but only with:

- Uniform products

- Balanced upstream and downstream processes

- Minimal changeovers

- Standard VFFS machines typically run 50–70 bags per minute, though multi-lane or customized systems can go higher.

Key insight: If your weighing, feeding, or downstream case-packing can’t keep up, HFFS speed becomes wasted capacity—not ROI.

Automation & Line Integration Considerations

This is where Hefestus-level thinking separates from machine resellers.

Floor Space & Line Architecture

Vertical vs horizontal orientation directly affects your facility layout.

VFFS machines: compact footprint, ideal for space-constrained plants ( vertical density).

HFFS machines: longer lines requiring space for infeed, sealing, cooling, and outfeed (horizontal expansion).

This impacts:

- Conveyor routing

- Robotics placement

- Secondary and tertiary packaging

Typical dimensions (machine body only):

| Machine | Length | Width | Height |

| VFFS | 1–2 m | 1–1.5 m | 2–3.5 m |

| HFFS | 3–10 m | 1–3 m | 1.5–2.5 m |

Always account for operator access, maintenance clearance, and upstream/downstream equipment.

VFFS fits tighter footprints.

HFFS integrates more naturally into complex, multi-stage automated lines.

Hygiene, Washdown & Food Safety

Orientation changes how contamination happens—and how fast you recover from it.

Key considerations:

- CIP vs manual cleaning requirements

- Seal contamination risk by orientation

- Open vs enclosed fill zones

Vertical drops increase the chance of product entering seal areas.

Horizontal systems often allow better isolation between fill and seal zones—critical in high-risk food environments.

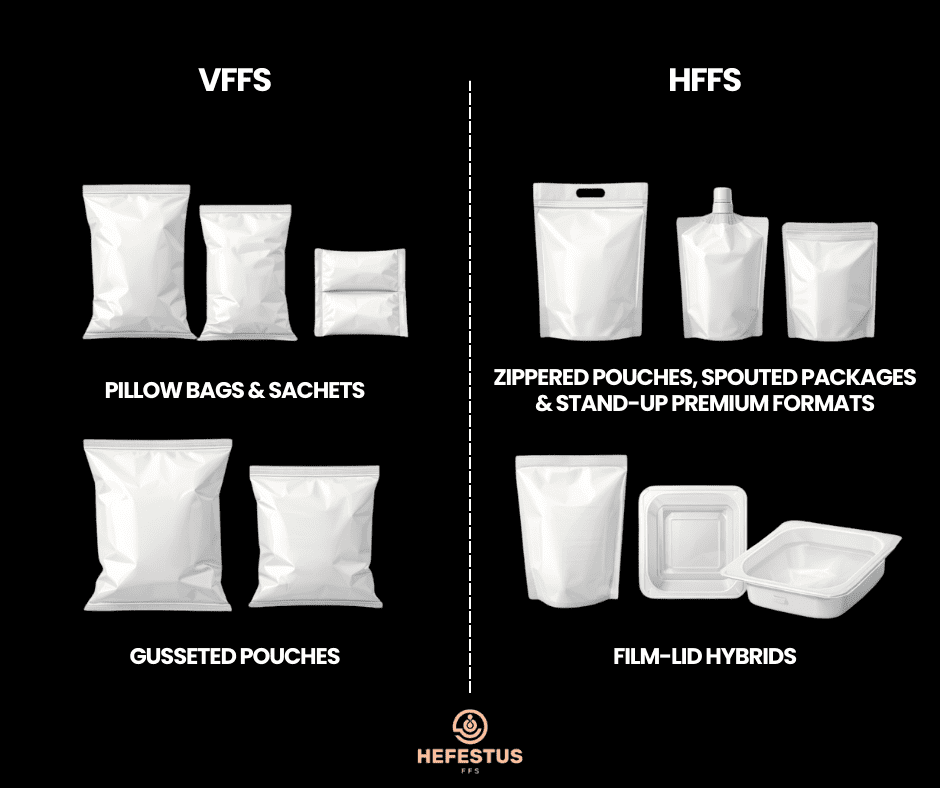

Packaging Formats & Sealing Flexibility

This is where production reality overrides spec sheets. Packaging format decisions directly affect seal integrity, line stability, hygiene risk, and long-term flexibility—making them a key differentiator in VFFS vs HFFS selection.

VFFS systems excel at standard bag styles with consistent, repeatable seal quality. They are optimized for high-volume applications where efficiency, reliability, and cost control matter more than customization.

VFFS strengths include:

- Pillow bags

- Sachets

- Gusseted pouches

These formats are efficient, highly repeatable, and well suited for cost-focused food production where simplicity supports throughput and sanitation efficiency.

HFFS systems prioritize flexibility and functional packaging design. Their horizontal architecture supports more complex forming and sealing operations, making them better suited for packaging that adds usability or brand value.

HFFS strengths include:

- Zippers and resealable closures

- Spouts and pourable features

- Film-lid hybrid structures

- Stand-up and premium packaging formats

Because of this, HFFS systems often allow greater branding freedom, while VFFS systems optimize for cost efficiency and operational simplicity. When packaging is part of the product’s function—such as resealability, controlled dispensing, or premium presentation—HFFS offers clear structural advantages.

Both systems can support MAP (modified atmosphere packaging), but implementation complexity differs significantly by orientation. Horizontal systems typically provide greater control over gas flushing and seal timing, while vertical systems favor faster, simpler integration when conditions allow.

Cost Reality — CAPEX, OPEX, and Scaling Pain

Forget fake price ranges. In food automation, decision-makers don’t win by minimizing purchase price—they win by controlling cost over time. The real difference between VFFS vs HFFS only becomes clear once capital cost, operating expense, and future scalability are evaluated together.

At a high level, the cost profiles of vertical and horizontal form fill seal machines diverge quickly.

VFFS systems typically offer:

- Lower initial capital investment

- Simpler maintenance requirements

- Faster operator onboarding and training

These advantages make VFFS machines attractive for operations prioritizing cost efficiency, compact layouts, and predictable production with limited format variation.

HFFS systems, by contrast, usually involve:

- Higher upfront capital expenditure

- More complex maintenance and change parts

- Greater long-term flexibility for formats, automation, and line expansion

This added complexity increases early costs, but it can pay off when product mix, branding requirements, or future automation demand adaptability.

The hidden cost most buyers underestimate is not the machine itself—it’s the cost of choosing the wrong architecture. Changing machines later is vastly more expensive than choosing correctly upfront. Line redesigns, operator retraining, sanitation revalidation, and lost production time destroy ROI far faster than any difference in purchase price ever could.

In short, the lowest CapEx rarely delivers the lowest cost per package. The right decision aligns machine orientation with product behavior and long-term production strategy—not short-term budget comfort.

👉 Changing the wrong machine later is vastly more expensive than choosing correctly upfront.

VFFS vs HFFS — Side-by-Side Decision Table

| Factor | VFFS | HFFS |

| Product type | Liquids, powders, granules | Solid, delicate, complex |

| Speed stability | High | High with complexity |

| Footprint | Compact | Large |

| Automation complexity | Lower | Higher |

| Hygiene demands | Moderate | High-control capable |

| Packaging formats | Standard bags | Premium & functional |

| Ideal use case | Cost-efficient volume | Flexible, scalable lines |

Common Buying Mistakes (and How to Avoid Them)

Even experienced food producers repeat the same mistakes when choosing between VFFS vs HFFS. These errors rarely show up during commissioning—but they surface later as hidden costs.

- Overbuying speed

Paying for maximum output you’ll never sustain once changeovers, sanitation, and downstream bottlenecks are factored in. - Ignoring changeover time

Short stops add up. Frequent SKU changes quietly erode productivity far more than lower nominal speed ever would. - Underestimating floor space requirements

Horizontal expansion, access clearances, and future automation often force expensive layout redesigns after installation. - Choosing based on price alone

The lowest CapEx almost never delivers the lowest cost per package over the life of the line.

Avoiding these mistakes requires evaluating product behavior, hygiene risk, and scalability—not just machine specs.

Which Form Fill Seal Machine Is Right for Your Food Operation?

Don’t ask “which is better?”

Ask the questions that actually determine success in VFFS vs HFFS for food automation:

- What does the product do when it moves?

Free-flowing products align naturally with VFFS. Products that splash, smear, deform, or separate under gravity often require the controlled handling of HFFS. - How often do SKUs change?

High SKU variability increases downtime, sanitation cycles, and operator error—making simplicity and fast changeovers more valuable than peak speed. - Is floor space or throughput the real constraint?

VFFS favors vertical density in tight facilities. HFFS supports higher output and complex line expansion when space allows. - Where does hygiene failure cost the most?

Seal contamination and difficult-to-clean zones drive scrap, downtime, and revalidation risk—often tipping the balance toward supported horizontal handling.

If these questions are answered honestly, the right vertical vs horizontal form fill seal machine usually becomes obvious.

Conclusion: Make the Decision That Scales With You

The VFFS vs HFFS decision isn’t about which machine is “better.” It’s about which one aligns with your product physics, production reality, and long-term automation strategy. Most operations don’t struggle because they lack information—they struggle because they optimize for the wrong variable, usually speed or upfront cost.

Successful food automation lines are designed around stability, hygiene, and scalability, not headline specs. That means matching machine orientation to how the product behaves, designing for changeovers and sanitation—not just steady-state output—and planning for growth before it becomes urgent.

Use this guide as a baseline, then pressure-test every assumption against your real constraints: product flow, SKU variability, floor space, and hygiene risk. The right choice becomes obvious when those factors are evaluated honestly.

If this helped clarify your decision, share it with your team or explore Hefestus’ related resources on packaging automation and industrial machinery.