Hand-Rolled Joints vs. Machine-Rolled Joints: What Cannabis Operators Need to Know

Whether you recently got your license or are scaling up, if you manufacture pre-rolls, you must eventually answer this question: hand-rolled or machine-rolled? The answer you choose will greatly affect your operation’s ability to scale as volume increases.

While hand-rolling can work at a small scale, it requires more employees, generates more waste, and makes it nearly impossible to consistently deliver quality results as demand increases.

On the other hand, operators may be wary of implementing an automated pre-roll machine and unsure of what that entails or how its workflows vary from traditional hand-roll production.

So, what exactly do you need to know when considering hand-rolled joints vs. machine-rolled joints for your pre-roll operation? We’ve compiled the ultimate guide for current and future operators to compare methods side by side and help you make the decision.

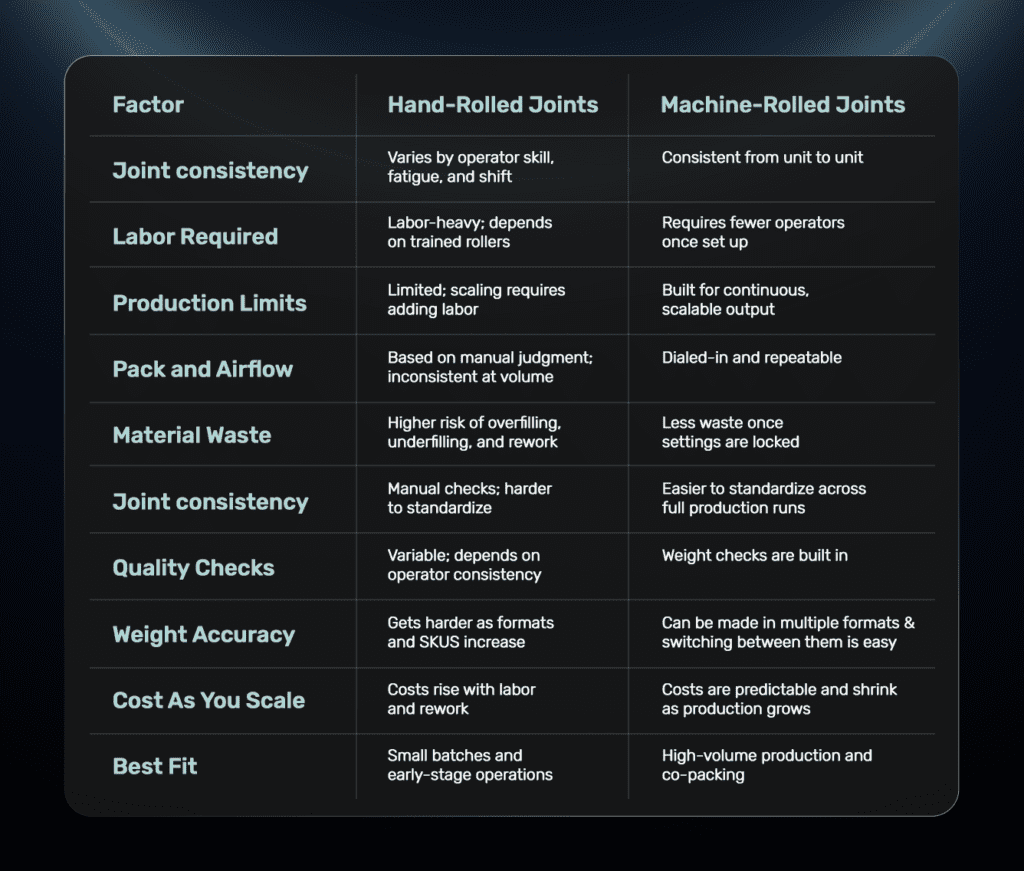

Hand-Rolled vs. Machine-Rolled Joints: At a Glance

What Hand-Rolled Means at Scale

As a nod to tradition, and in honor of the flower inside, many operators, especially small-batch and craft producers, opt for hand-rolling. In fact, the terminology of “hand-rolled” is often used in packaging and marketing to signal a higher level of care for consumers.

While hand-rolling does work for limited releases, small batches, or early-stage startups, the term “hand-rolled” doesn’t signal to consumers the challenges and disadvantages the method creates for their favorite cultivators and producers behind the scenes.

True hand-rolled joints are made entirely by hand, from start to finish. The employee will form, shape, fill, roll, and seal the paper, all by hand. Hand-packed cones, on the other hand, use a pre-formed cone that’s manually filled with the ground flower material.

In real-time production environments, manual workflows are tedious and repetitive for employees who perform the same actions repeatedly. Team members quickly become fatigued, and quality often declines by the end of shifts.

Moreover, because filling is a skill, you’ll quickly notice shift-to-shift variability in quality. Overall, these hand-rolling or hand-packing challenges lead to inconsistent results, making it nearly impossible for operators to scale.

When hand-rolling operators see an uptick in demand, they often implement hybrid workflows that combine manual work with automation. For instance, simple tools or semi-automated equipment will be used for filling, with human input still required for most steps.

These systems reduce some variability, but they don’t fully remove it. All in all, hand-rolling isn’t necessarily “bad”; in fact, many operators start with hand-rolling. The method, however, isn’t scale-appropriate and will ultimately limit your operation’s growth.

The Hidden Costs of Hand-Rolled Production

Of course, the downside of hand-rolled production is the hidden costs it entails. In real-time production, hand-rolling becomes increasingly difficult to manage as soon as volume increases.

These frictions negatively affect crucial components of the workflow, from team morale to increased waste. Before we move on, let’s review the most influential inefficiencies that quickly translate into higher costs at higher volumes.

- Labor volatility: Hand-rolling is a monotonous process, especially when performing the same motions day in and day out. This results in day-to-day fatigue, chronic absenteeism, and high turnover in the role. When replacing a position repeatedly, you’ll be faced with ongoing high training costs, too.

- Throughput unpredictability: Because of labor issues and unstandardized processes, it’s nearly impossible to predict consistent results in volume and quality when hand-rolling. This unpredictability creates volatility across operations when you can’t reliably forecast outcomes to keep up with current or rising demand.

- Inconsistent density: Even worse for operators is when customers experience inconsistent density within pre-rolls during consumption. This leads to uneven burning and pre-rolls that are difficult to draw, which affects customer return rates and loyalty. Furthermore, when detected during production, inconsistent densities lead to additional rework or rejects, increasing waste costs.

- Difficulty standardizing: Hand-rolling is also incredibly difficult to standardize due to the varying factors that affect the overall workflow. This puts quality assurance at risk and creates compliance challenges over time. When systems can’t be standardized to ensure repeatable output, it can hinder an operation’s scalability.

- Increased waste: Human errors lead to increased waste, period. Whether overfilling or underfilling, or packing or sealing poorly or incorrectly, hand-rolling naturally incurs higher waste costs than machine-rolling. From paper to flower material, waste quickly compounds into a measurable cost.

What Machine-Rolled Production Solves

After experiencing the hidden costs of hand-rolling, many operators turn to automated pre-roll machines to overcome these challenges and scale. Operationally, automation streamlines the hand-rolling workflow, reducing touchpoints overall.

First and foremost, this standardizes the packing density. From joint to joint, machines can fill at the exact same density, delivering consistent results that reduce waste and support even burns.

Machine-assisted workflows also reduce waste by dialing in weight. This repeatable accuracy reduces rejects and rework, improving quality assurance and compliance standards while also supporting consistent results.

Another part of compliance that becomes increasingly difficult when scaling volume, hand-rolling, is batch tracking. Pre-roll automation equipment also standardizes tracking across batches to avoid costly fines or regulatory issues.

When standardizing each step, machine-rolled workflows also produce a consistent volume, making it easier to forecast and plan growth. This predictable hourly output is nearly impossible to achieve with hand-rolling, given the many factors that can affect efficiency.

Finally, in today’s modern market, the key to scaling is multiple SKUs, especially infused product categories. For hand-rolling processes, adding these variables only complicates the process, quality control, and throughput.

Automation empowers you to produce multiple SKUs with consistent, reliable quality that supports optimal (and predictable) margins once on the shelves.

But let’s be clear about one thing. Hand-rolling does not mean lower quality. It’s just harder to achieve consistent quality, given that an even burn depends on grind, moisture, and compaction control.

Machines help make these variables more controllable, supporting long-term sustainability.

Where Machine Rolling Falls Short

Of course, no process or method is without its own disadvantages or downfalls, and there are areas where machine rolling falls short that you should consider.

For instance, not all equipment can be treated equally. Poorly designed or low-quality equipment can actually hurt your operation or its ability to scale. It can generate additional waste due to poor mechanisms or cause downtime during troubleshooting or repair.

Not only that, but investing in equipment that can’t scale with you can limit the formats you can produce efficiently. Some machines are limited to specific paper types and sizes, or they can’t handle infused material effectively, which can hinder growth.

Another factor that varies from machine to machine is the manufacturer’s setup and training. If equipment is set up incorrectly or a component isn’t working properly, it can lead to inconsistent outputs and airflow issues for consumers.

Finally, it’s important to ensure you don’t overinvest before demand in your market. Automation works best when it aligns with volume, SKU mix, and your operation’s growth trajectory.

Why Most Operators Eventually Transition to Automation

That said, most operators eventually transition to automation. In the start, it’s only natural to begin hand-rolling, especially when it requires little upfront investment.

During the early stages, with a small team, many craft and startup brands can withstand hand-rolling as they grow. But as volume increases, so do the challenges we discussed earlier in this guide.

The natural progression to scale output is towards automation. Typically, there are a few factors that trigger the switch, including:

- Retail expansion: Increased demand from retailers requires higher volume, which can strain hand-rolling operations or significantly affect workflow consistency and quality.

- Infused SKUs: The demand for infused SKUs isn’t going anywhere. With numerous variables to consider, operators with automated workflows are more likely to achieve consistent quality in infused SKUs, leading to repeat purchases and greater success.

- Multi-pack formats: Another trend that strains hand-rolling operations is the shift toward multi-packs, which require higher overall volumes. Automation supports this SKU expansion by streamlining filling and finishing and shifting labor to packaging roles.

- Wholesale consistency demands: Wholesale buyers expect uniform weight, airflow, and appearance across all units and orders. As order sizes grow, maintaining that level of repeatability becomes difficult with manual workflows, prompting operators to automate to protect brand trust and reduce rework.

Scaling with Automation: The Hefestus AuraX

As production scales and variability becomes harder to manage, operators often transition to the Hefestus AuraX. Our flagship pre-roll machine helps address common hand-rolling challenges and delivers the features required for sustainable, long-term growth.

The AuraX is one of the few pieces of equipment that offers high-volume, multi-format production. While some machines only produce straight rolls or only fill cones, the AuraX is specifically engineered for SKU flexibility.

It handles infused SKUs, cones, and straight rolls in all weights and sizes, with minimal changeover and only one operator required to run the system. This uptime, consistent output, higher volume, and lower labor costs are key to supporting a facility’s ability to scale.

Conclusion: Which Approach Fits Your Operation?

Which approach best fits your operation? In this guide, you’ve learned that there’s still a time and place for hand-rolling. However, just because it’s not obsolete doesn’t mean it’s the best route for your facility’s workflow.

And while machine-rolling can have a bad reputation as a shortcut, advances in automation technology are changing that. As the industry evolves, every operation will reach a ceiling where automation is required to scale sustainably.

That’s where the most advanced automation adopters will gain a competitive advantage. Whether you’re just starting up or seeking to make a change sooner than later, the smartest operators plan for the next phase before the current stage’s challenges.

Save or share this guide to ensure you’re protecting your operation’s bottom line and brand reputation with the right approach at the right time.

Hand-Rolled Joints vs. Machine-Rolled Joints: Frequently Asked Questions

Keep reading for the most frequently asked questions from operators considering hand-rolled vs. machine-rolled joints for their operations.

Is it better to roll by hand or use a machine for cannabis production?

It’s better to roll by hand in certain instances, and it’s better to use a machine in others. For cannabis production, the type of rolling method you use at your facility will depend on size, demand, labor, and plans for growth.

At what volume does hand-rolling stop making sense?

At what volume hand-rolling stops making sense depends on how much labor strain, inconsistency, and rework an operation can manage. As monthly output increases, fatigue and workflow bottlenecks become harder to manage, reducing consistency and quality. This is usually the trigger for exploring machine-rolled workflows.

Are machine-rolled joints lower quality than hand-rolled joints?

Machine-rolled joints are not inherently lower quality than hand-rolled joints. Quality is driven by material inputs and process control, rather than by the method itself. Automated workflows help ensure consistent weight, airflow, and density across all units.

Can machine-rolled joints still look hand-finished?

Machine-rolled joints can still look hand-finished when automation is paired with thoughtful finishing steps. More advanced, higher-quality machines automate filling and shaping while preserving a handcrafted visual appearance. This approach allows teams to scale without sacrificing presentation.