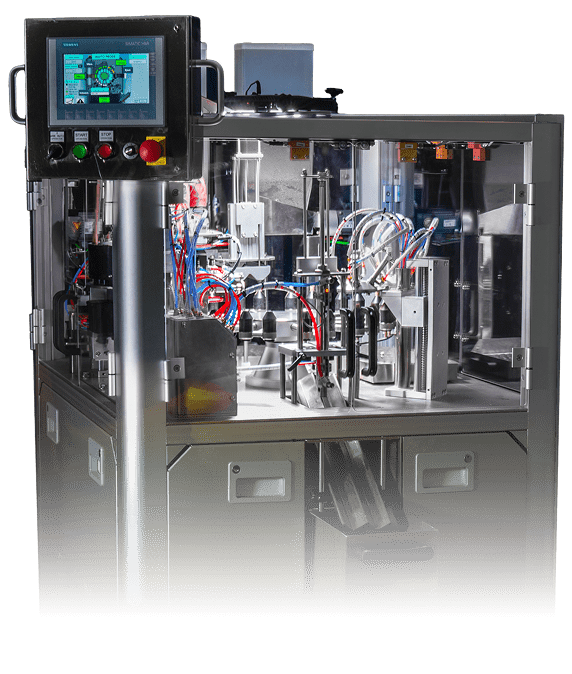

The Hefestus AuraX is a fully automated pre-roll machine capable of producing 2,000+ joints per hour – across every style and size imaginable – with a single operator. Cut labor costs and capture new market opportunities with the pre-roll machine built for the next era of cannabis automation.

Delivering advanced automation solutions that merge precision

Automation pays for itself faster than you think – cut labor costs by up to 90% while boosting consistency and output with AuraX.

2000+ pre-rolls per hour

Saves you $1300+ in labor per shift

Scaling Automation that Works for Cannabis Processing

“No real downtime”

“One of the best parts about Hefestus is their customer service. You don’t have to worry about being left hanging, they’ll call you back, and you’ll talk to a real person. If you need a part, there’s no real downtime because they include a full toolbox of spares. And if something else comes up, they’ll overnight it to you.”

Dan, Jacked

“Running hands off quickly”

“Onboarding was extremely simple. Hefestus reached out, gave us an ETA of when the machine would arrive, and shortly thereafter when their team would arrive to onboard. By the end of the first day, my team was running hands off.”

Mike Lempert, Seed & Smith

“Every joint the same”

“I was at a friend’s facility and saw the Hefestus machine in operation. I was impressed with the efficiency, the minimal labor required, and the consistency: every joint coming out the same. That got my attention.”

Noah, Pioneer Interests

“Four people to one”

“It took about four people, five days a week, to roll anywhere between 8,000 and 10,000 joints. Now, with the Hefestus, we can roll that amount with one person in about a day.”

Katie, Collective Elevation

“One of the simplest machines to work on”

“My background is in maintenance. I can tell you the Hefestus pre-roll machine is, hands down, one of the simplest machines to work on mechanically.”

David, Garden Green

“Zero problems with it”

“Everything you said the machine would do, it does. We’ve had zero problems with it.”

Jimmy, Brute’s Roots

“The service has been spot on”

“You’re extremely responsive, very thorough with your follow-ups, and always checking in to see how the machines are performing.”

David, Ascend

“No real downtime”

“One of the best parts about Hefestus is their customer service. You don’t have to worry about being left hanging, they’ll call you back, and you’ll talk to a real person. If you need a part, there’s no real downtime because they include a full toolbox of spares. And if something else comes up, they’ll overnight it to you.”

Dan, Jacked

“Running hands off quickly”

“Onboarding was extremely simple. Hefestus reached out, gave us an ETA of when the machine would arrive, and shortly thereafter when their team would arrive to onboard. By the end of the first day, my team was running hands off.”

Mike Lempert, Seed & Smith

“Every joint the same”

“I was at a friend’s facility and saw the Hefestus machine in operation. I was impressed with the efficiency, the minimal labor required, and the consistency: every joint coming out the same. That got my attention.”

Noah, Pioneer Interests

“Four people to one”

“It took about four people, five days a week, to roll anywhere between 8,000 and 10,000 joints. Now, with the Hefestus, we can roll that amount with one person in about a day.”

Katie, Collective Elevation

“One of the simplest machines to work on”

“My background is in maintenance. I can tell you the Hefestus pre-roll machine is, hands down, one of the simplest machines to work on mechanically.”

David, Garden Green

“Zero problems with it”

“Everything you said the machine would do, it does. We’ve had zero problems with it.”

Jimmy, Brute’s Roots

“The service has been spot on”

“You’re extremely responsive, very thorough with your follow-ups, and always checking in to see how the machines are performing.”

David, Ascend

Swipe left for more quotes

We created the AuraX to solve the issues we saw operators in cannabis facing as they scaled their operations.

The AuraX is built for versatility. Operators can run cones of all sizes, straights, infused pre-rolls, and blunts on the same platform with quick changeovers and precise, repeatable results. Whether you’re scaling a craft brand or managing high-volume production, the AuraX adapts to your process without compromise.

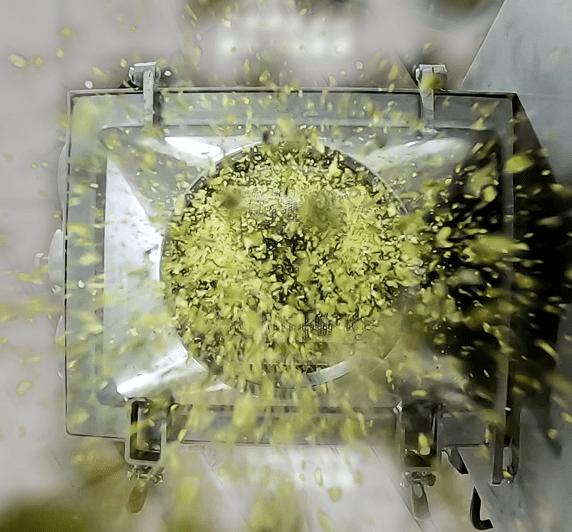

Our machine keeps you moving forward into the future by being able to handle sticky, infused material to ensure you can deliver products consumers love.

Manual tasks are boring for humans; empower your staff to focus on fulfilling tasks & scale operational efficiencies.

Downtime can destroy your profits. The AuraX ensures your line stays running & pumping out joints. Easy cleaning ensures a smooth transition between SKUs & input material.

We do a full-week training to ensure you are comfortable with the machine. We know things happen & you’ll need support. We are proud to offer 24/7 technical support to ensure you never have to try & figure things out alone & your operations remain active.

Consult with Sales about financing options so you can choose the best automated pre-roll machine. It’s important to look beyond the marketing and compare each model’s output, compatible formats, and overall cost.

Talk to our knowledgeable team today.

The AuraX is the only commercial pre-roll automation system that can run cones, straight-wall cigarette-style tubes, and hemp blunt wraps. It supports all types of tips and crutches, including glass, ceramic, and wood.

Yes. The AuraX’s feeding system allows operators to run highly infused, sticky flower with consistency and minimal clogging. Brands like STIIIZY, the #1 pre-roll brand in North America, trust AuraX for their infused pre-rolls.

The AuraX supports cones, straight-roll papers, and blunt wraps, giving you maximum flexibility.

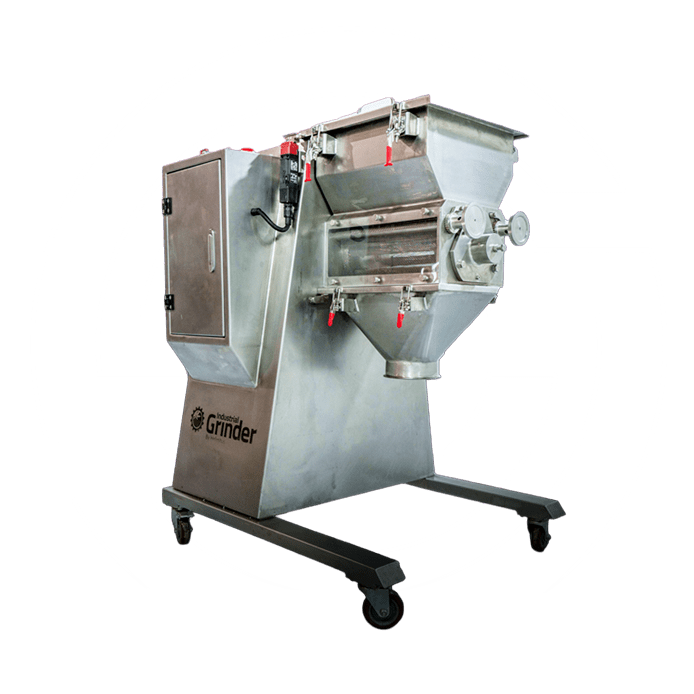

The cone cutting station lets operators standardize cone inventory by purchasing one size (e.g., King Cones) and cutting them down for smaller SKUs (.7g, .5g, .3g). It also allows you to adjust for strain density, since different flower densities require different cone lengths for proper pack consistency.

Yes. You can adjust pre-roll weights to match your exact SKUs and consumer demand. As part of the week-long training you get from our technicians when you purchase an AuraX, we’ll help you create SOPs for every type of pre-roll you want to produce.

Each pre-roll is finished with the patented Dutch Crown (fold), the premium, flat-top finish preferred by top brands and consumers alike. It burns smoother, lights easier, and eliminates canoeing caused by twist tips.

Yes. Once a pre-roll spec is calibrated (e.g., pack pressure, material density, cone size), the system can save it as a recipe. Operators can switch between SKUs with just a few taps on the touchscreen interface.

The AuraX runs on 120V single-phase power at 60 Hz and draws up to 20 A.

For pneumatics, it requires clean, dry compressed air with:

Exact requirements may vary slightly based on your specific configuration, but this covers the typical power and air needs.

One operator can run the AuraX efficiently, reducing labor costs for pre-roll production and freeing your staff to work on higher-impact initiatives.

The AuraX can produce up to 2,000+ pre-rolls per hour depending on configuration and material type.

Yes. Our joint rolling machine includes reporting tools for throughput, consistency, and production data.

The dimensions are as follows: 920 mm / 36.2 in x 1020 mm / 40.2 in x 1413 mm / 55.6 in (height).

Hefestus has 30+ years of automation experience across cannabis, food, and pharma packaging. We do more than just manufacture machines – we build integrated automation systems designed to grow with your business.

We stay on-site for multiple days after installation, ensuring your entire team is fully trained before we leave. We also provide a full digital resource library (manuals, videos, and SOPs) for fast retraining when you onboard new operators.

We offer 24/7 technical support with service technicians located across multiple time zones – including Israel and the U.S. West Coast, Mountain, and East Coast. You’ll always reach a real person who can help.

Yes. Hefestus offers flexibility if you need to upgrade or switch machines. We support trade-ins and buybacks for clients expanding capacity or adopting new features.

(Exact program terms depend on region and agreement.)

For those who qualify, we offer 0% down and fixed monthly payments – typically around $7,800/month for 36 months. Unlike subscription or per-joint pricing models, your payment never increases as you scale, and you own the machine after 3 years.

We’ll work with you until it does. If issues persist, we have a flexible buyback and support policy to ensure no operator is left behind.

Yes, automated pre-roll machines are worth the investment if your operation is currently producing 10-30k pre-rolls per month and looking to scale past that. While the AuraX is a significant upfront investment, it will pay it back quickly because you’ll be able to rapidly scale the number of pre-rolls – and pre-roll styles – you can produce, helping you meet demand and aggressively expand into new pre-roll segments.

The benefits of automated pre-roll machines for your business are numerous; by automating your pre-roll line, you can cut labor costs by up to 90%, increase production consistency, and expand SKU diversity — unlocking new product categories (infused, blunts, mini-dogwalkers, etc.).

Absolutely. The AuraX allows seamless switching between cone sizes, paper types, and materials so you can produce multiple SKUs from a single system.

Accelerant uses a per-pre-roll pricing model ($0.09-$0.11 each), meaning your costs grow as your production grows, and you never own the machine.

With Hefestus, you make one predictable monthly payment (no tolling or per-piece fees) and own the machine outright after 3 years.

For high-volume producers, this equates to tens of thousands in savings every year.

Yes. Hefestus offers auto-tubing, labeling, counting, and sealing systems that integrate directly with AuraX, making it the industry’s first end-to-end pre-roll automation ecosystem.

Automated systems produce uniform pre-rolls with consistent pack density and burn performance, creating a premium, repeatable product that builds consumer trust and loyalty.

Infused pre-rolls now account for 44% of all pre-roll sales in North America. The AuraX can handle sticky infused flower with ease, helping you reach nearly half the market that twist-tip systems can’t serve effectively.

Get expert guidance on scaling your automation line — from food to cannabis and everything in between.

Get expert guidance on scaling your automation line — from food to cannabis and everything in between.

Share your details, and we’ll help you explore the right solutions for your business.