Cup Sealing Methods Explained

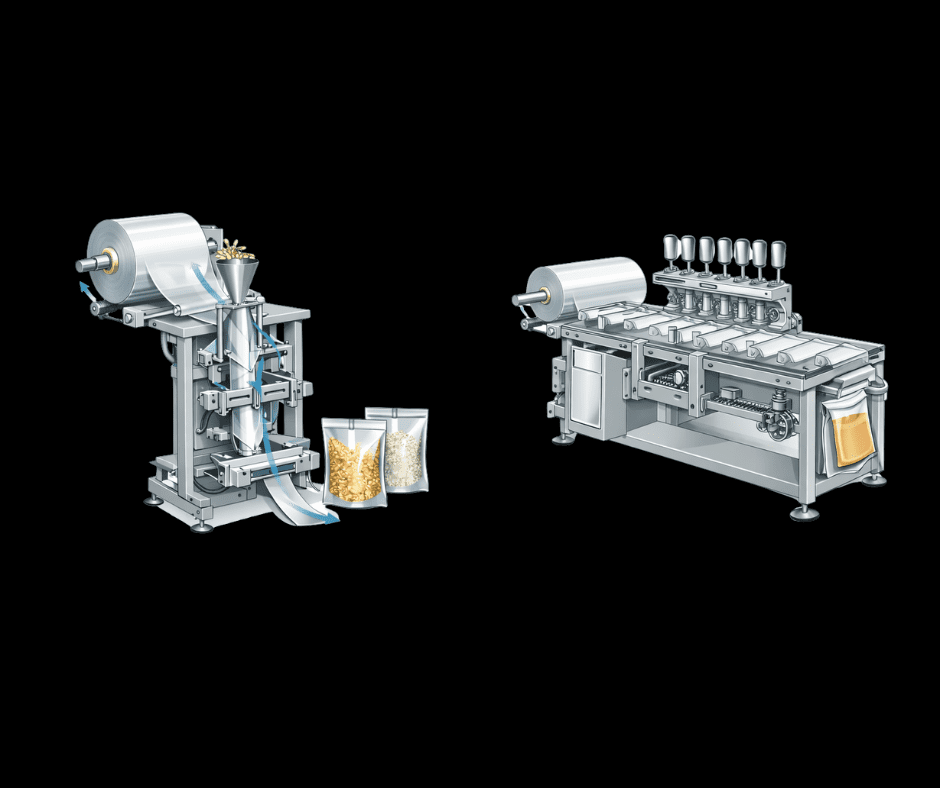

In the refrigerated salsa market, packaging plays a crucial role in preserving freshness, extending shelf life, and providing convenience for consumers. One of the most common formats for salsa is single-serve cups, which can be sealed in several ways depending on production needs, shelf-life requirements, and branding goals.

Understanding these cup sealing methods is essential for manufacturers using a salsa packaging machine, ensuring that each package is secure, attractive, and maintains product quality.

Film Sealing

Film sealing is one of the most widely used methods for single-serve salsa cups. This method involves applying a thin plastic film over the cup opening and heat-sealing it to create an airtight barrier.

Key benefits of film sealing

- Cost-Effective: Film rolls are generally less expensive than pre-formed lids, making it ideal for high-volume production.

- Customizable: Films can be printed with logos, nutritional info, or promotional messaging for marketing purposes.

- Tamper-Evident: Heat-sealed films provide visible evidence if a package has been opened or compromised.

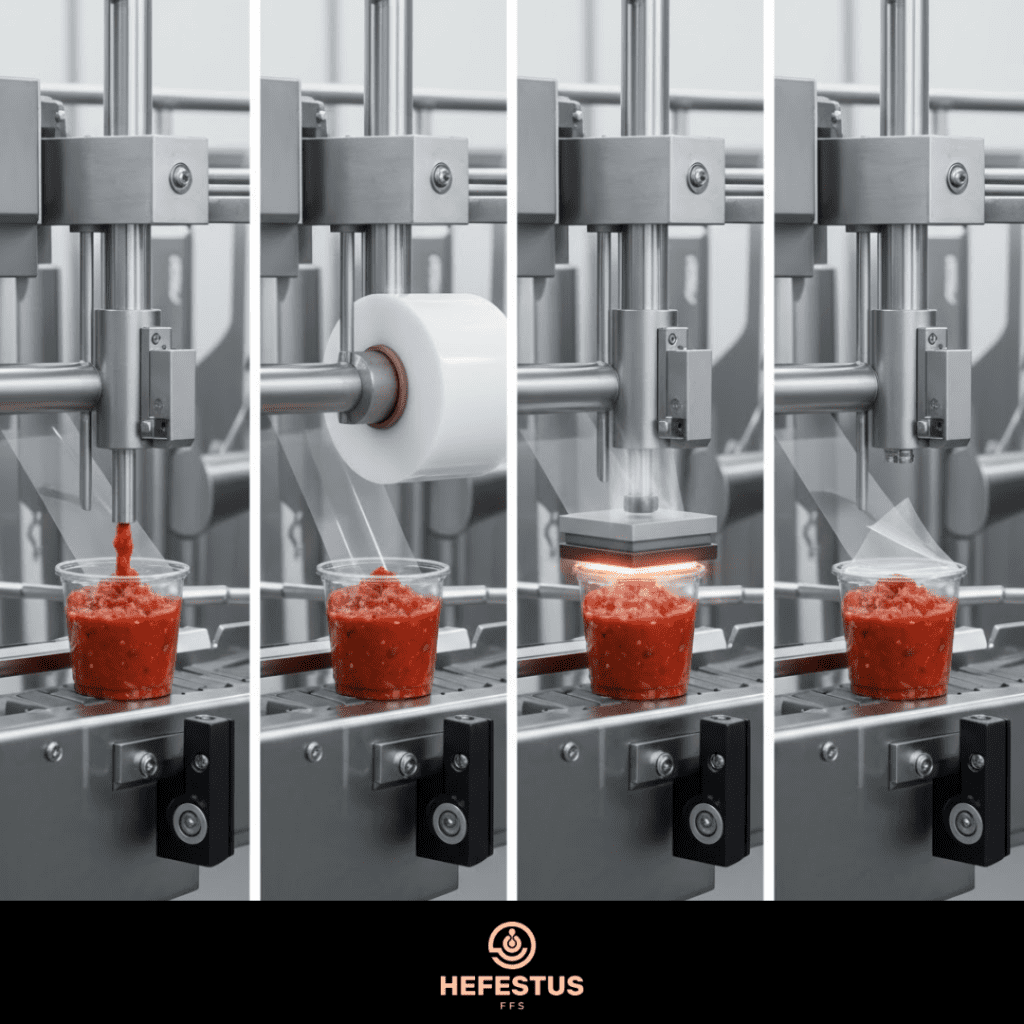

How it works

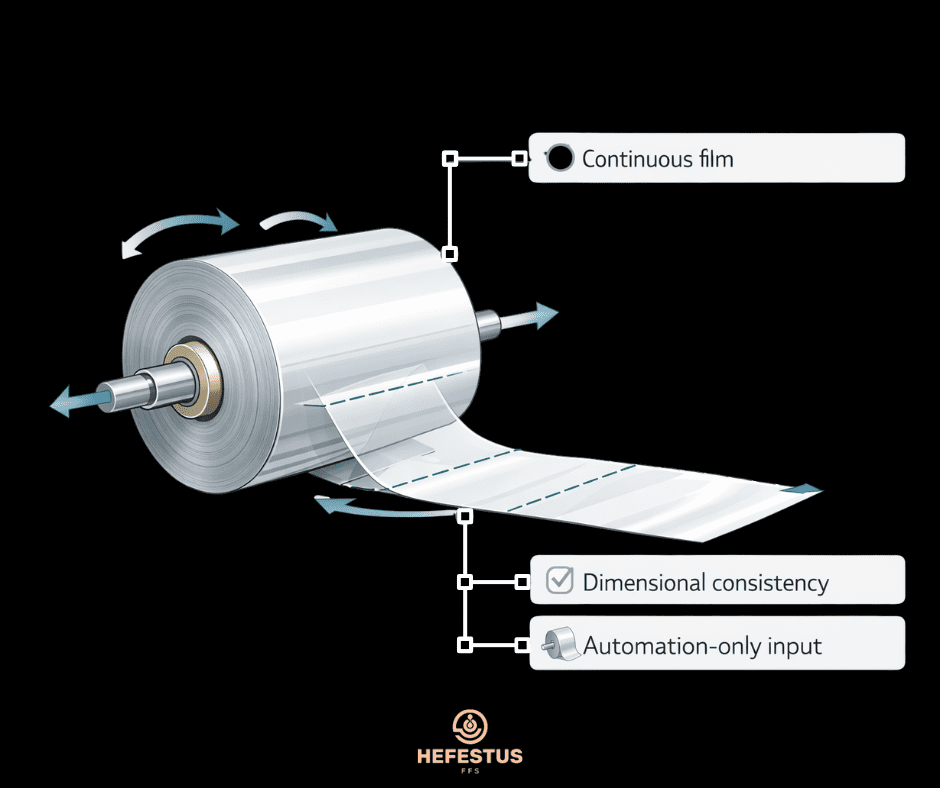

- Cups are filled with salsa using a specialized automation packaging machine.

- The film is fed from a roll and positioned over the cup.

- Heat and pressure are applied to seal the film securely.

- The sealed cups are cooled and ready for distribution.

Film sealing is particularly effective for products with short to medium shelf life, providing a secure seal without adding significant material costs.

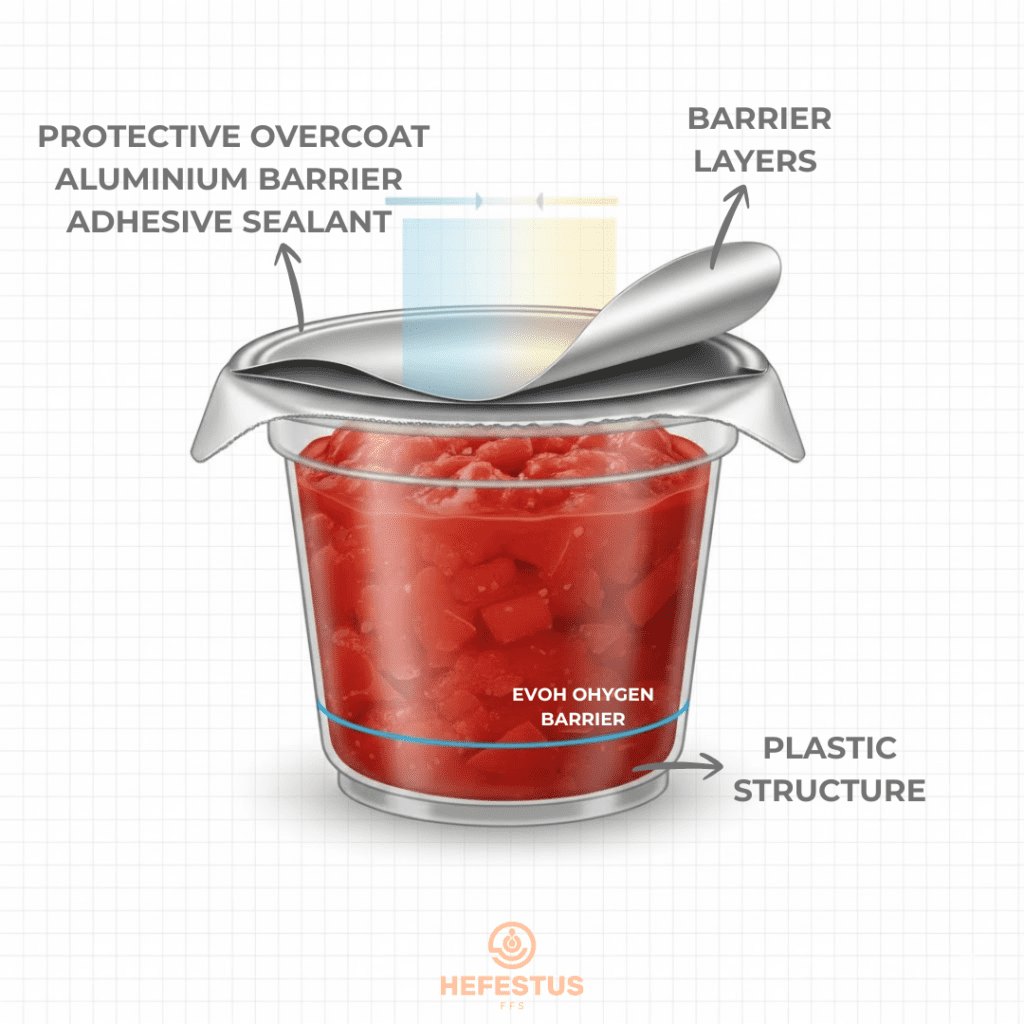

Foil Sealing

Foil sealing uses a thin layer of aluminum foil instead of plastic film. Foil provides a stronger barrier against oxygen, moisture, and light, which can help preserve the color and flavor of salsa for longer periods.

Advantages of foil sealing

- Extended Shelf Life: Superior barrier properties help maintain freshness in refrigerated conditions.

- Premium Appearance: Foil seals are often associated with higher-quality products and can enhance brand perception.

- Good for MAP Integration: Foil works well with Modified Atmosphere Packaging (MAP) for longer-lasting products.

Process overview for foil sealing

- The cup is filled with salsa.

- A foil lid is placed on top, either manually or automatically using an automated machine.

- Heat and/or pressure are applied to bond the foil to the cup.

Foil seals are often used for premium salsas or products that require extended shelf life and extra protection against spoilage.

Pre-Cut Lids

Pre-cut lids are rigid plastic or paper lids that snap onto the cup after filling. This method is popular for ready-to-eat products in supermarkets and convenience stores because it offers convenience for consumers.

Benefits of pre-cut lids

- Consumer-Friendly: Easy to open and re-close, ideal for on-the-go consumption.

- Stackable: Cups with rigid lids can be stacked safely for transport and storage.

- Branding Opportunities: Lids can be printed with logos, nutrition information, or promotional designs.

Sealing process

- Salsa is filled into the cup.

- The pre-cut lid is placed on top and pressed or snapped into place.

- Some machines can apply a secondary seal underneath the lid for added freshness.

Pre-cut lids are particularly suitable for products where convenience and aesthetics are key, such as snack packs or meal kits.

Modified Atmosphere Packaging (MAP) for Cups

Modified Atmosphere Packaging (MAP) can be used in combination with film, foil, or pre-cut lids to extend shelf life. In MAP, the air inside the cup is replaced with a controlled mixture of gases, typically nitrogen and carbon dioxide, to slow spoilage and maintain color, flavor, and texture.

Key advantages of MAP

- Extended Freshness: Slows microbial growth and oxidation, keeping salsa fresh longer.

- Visual Appeal: Maintains bright color and texture, making products more attractive on shelves.

- Reduced Preservatives: Helps preserve quality without relying on chemical additives.

MAP sealing steps

- The cup is filled with salsa using a packaging machine.

- The package is flushed with the desired gas mixture.

- The lid or film is sealed immediately to maintain the modified atmosphere.

- Packages are labeled and stored under refrigeration.

MAP is particularly beneficial for premium salsas, products shipped over long distances, or items that need a longer refrigerated shelf life.

Comparing Cup Sealing Methods

Here’s a quick comparison to help producers decide which sealing method best fits their needs:

| Sealing Method | Shelf Life | Cost | Consumer Convenience | Branding Potential | Ideal Use Case |

| Film | Short–Medium | Low | Moderate | High | Everyday snack packs, high-volume production |

| Foil | Medium–Long | Medium | Moderate | Premium | Refrigerated premium products, MAP integration |

| Pre-Cut Lids | Short–Medium | Medium | High | High | On-the-go packs, meal kits, retail convenience |

| MAP | Medium–Long | Medium–High | Moderate | High | Long-distance shipping, premium refrigerated products |

Tips for Optimizing Cup Sealing

To get the most out of your cup sealing process, it’s important to follow best practices that ensure each package maintains freshness, integrity, and visual appeal.

- Select the right sealing material: Consider the type of salsa, shelf-life requirements, and storage conditions.

- Calibrate the machine: Ensure your packaging machine is correctly calibrated for temperature, pressure, and speed to avoid leaks or weak seals.

- Quality control: Regularly inspect seals for integrity and consistency to maintain freshness and consumer trust.

- Combine methods: Film sealing with MAP, for example, can offer both cost-effectiveness and extended shelf life.

Implementing these tips helps maximize the efficiency of your salsa packaging machine, reduces product waste, and ensures that every cup of salsa reaches consumers in perfect condition.

Conclusion

Choosing the right cup sealing method is essential for maintaining the quality, freshness, and appeal of refrigerated salsa. Film, foil, pre-cut lids, and MAP each have unique advantages that cater to different production, retail, and consumer needs. By understanding these methods and using a reliable packaging machine, producers can ensure their products are safely packaged, visually appealing, and ready for the market.

The right sealing method can also enhance brand perception, reduce waste, and extend shelf life, making it a critical consideration for any salsa manufacturer looking to stay competitive in today’s food industry.