Dairy Packaging Trends

Margins are tighter. Shelf-life tolerance is shrinking. Labor is harder to find. Distribution footprints are stretching farther than ever.

Against this backdrop, dairy packaging trends are no longer about swapping materials or redesigning labels. They’re about process control, automation, and shelf-life precision. Dairy producers that still think packaging equals “the container” are already behind.

This guide breaks down the dairy packaging market trends that actually matter—not marketing fluff, not recycled sustainability talking points. You’ll learn how automation, fill accuracy, sealing integrity, and atmosphere control are now defining competitiveness in dairy.

Why Dairy Packaging Is Changing Faster Than Other Food Categories

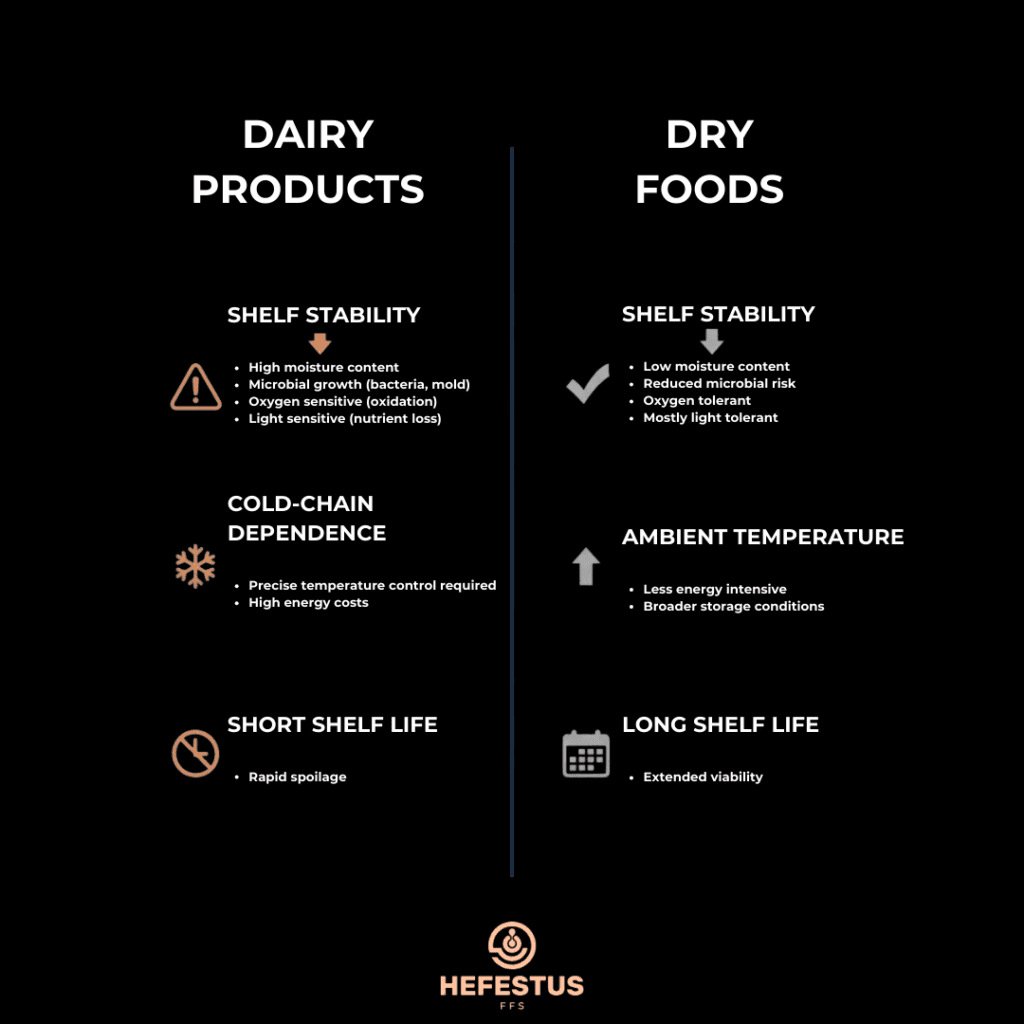

Shelf-Life Sensitivity in Dairy Products

Dairy exposes weak packaging systems faster than almost any other food category because it combines:

- High moisture content

- High microbial risk

- Strong sensitivity to oxygen and light

- Dependence on cold-chain integrity

Unlike dry snacks or shelf-stable foods, dairy has very little forgiveness. A minor seal inconsistency, oxygen pocket, or hygiene lapse can collapse shelf life—and margins—overnight.

Insight: Dairy packaging trends are accelerating because dairy punishes process variation more severely than most foods.

Distribution Expansion Is Forcing Packaging Upgrades

What worked for a regional dairy brand often breaks at scale.

Longer routes mean:

- Higher oxygen exposure risk

- More seal stress during transport

- Tighter tolerance for leaks and weight variation

Local success doesn’t translate automatically to national or export distribution. That’s why dairy packaging market trends are shifting from material choice to process reliability.

Trend #1 – Shelf-Life Extension Through Packaging Process Control

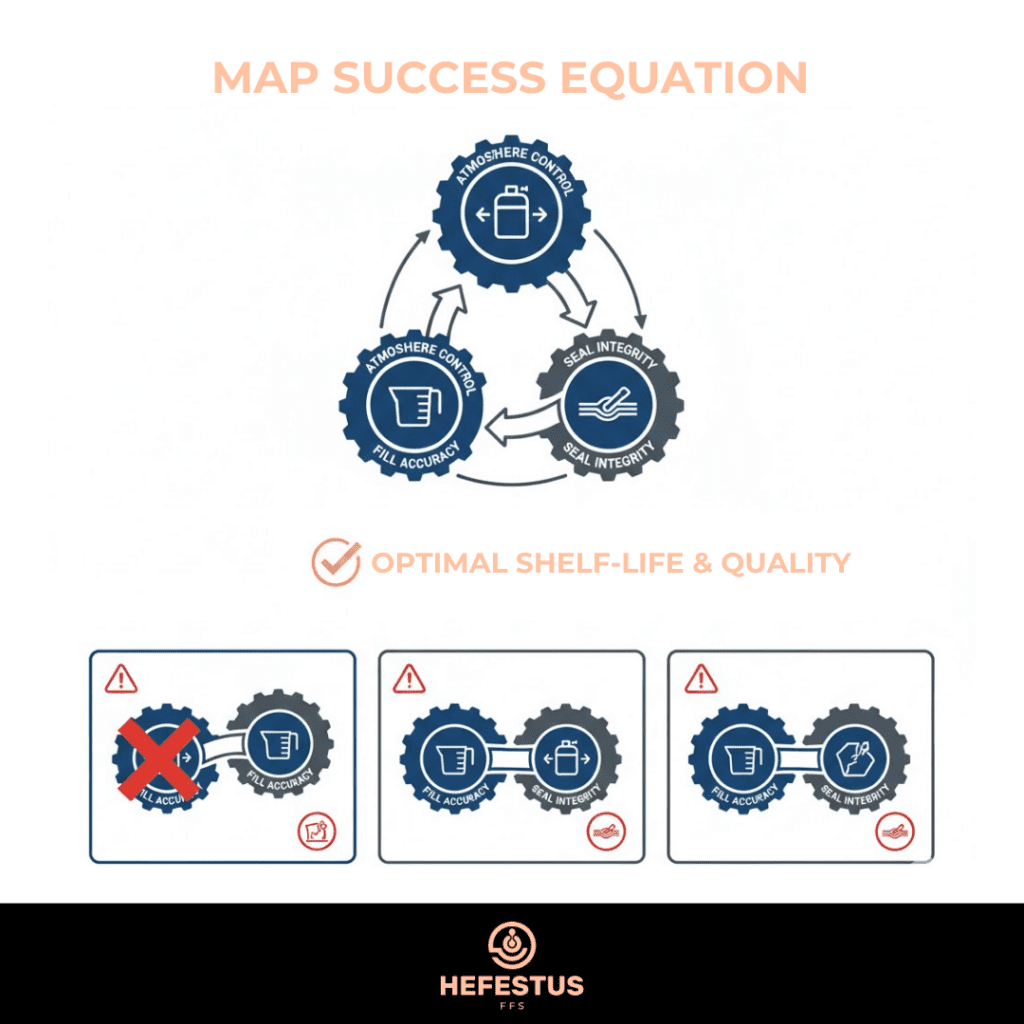

Modified Atmosphere Packaging (MAP) Is Becoming Standard

MAP is no longer “advanced”—it’s becoming baseline for competitive dairy producers.

Once reserved for meat, MAP is now common in:

- Yogurt and cultured products

- Cheese (fresh, sliced, shredded)

- Dairy-based dips, spreads, and sauces

The critical shift: MAP only works if filling and sealing are precise. Gas flushing without consistent fill volumes and seal integrity is just false security.

Key takeaway: Shelf life is increasingly determined by process repeatability, not packaging material alone.

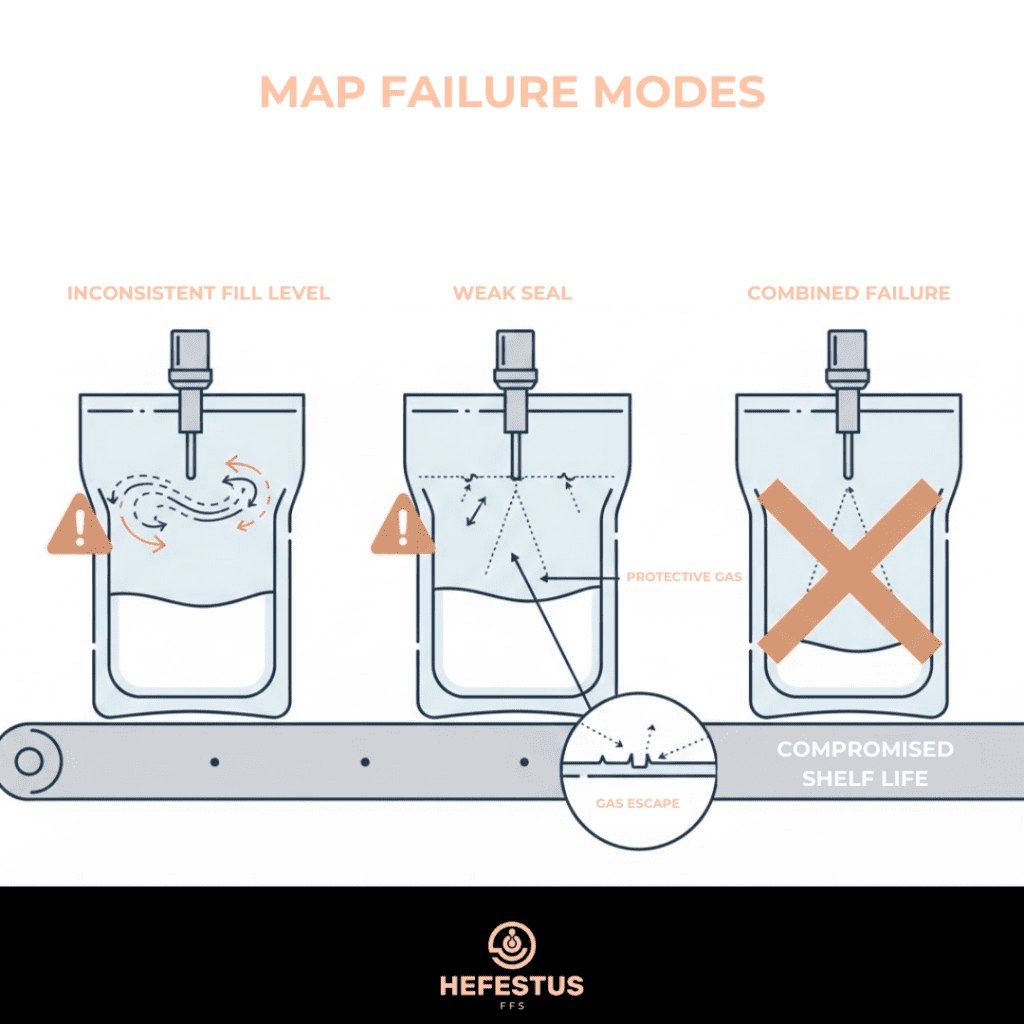

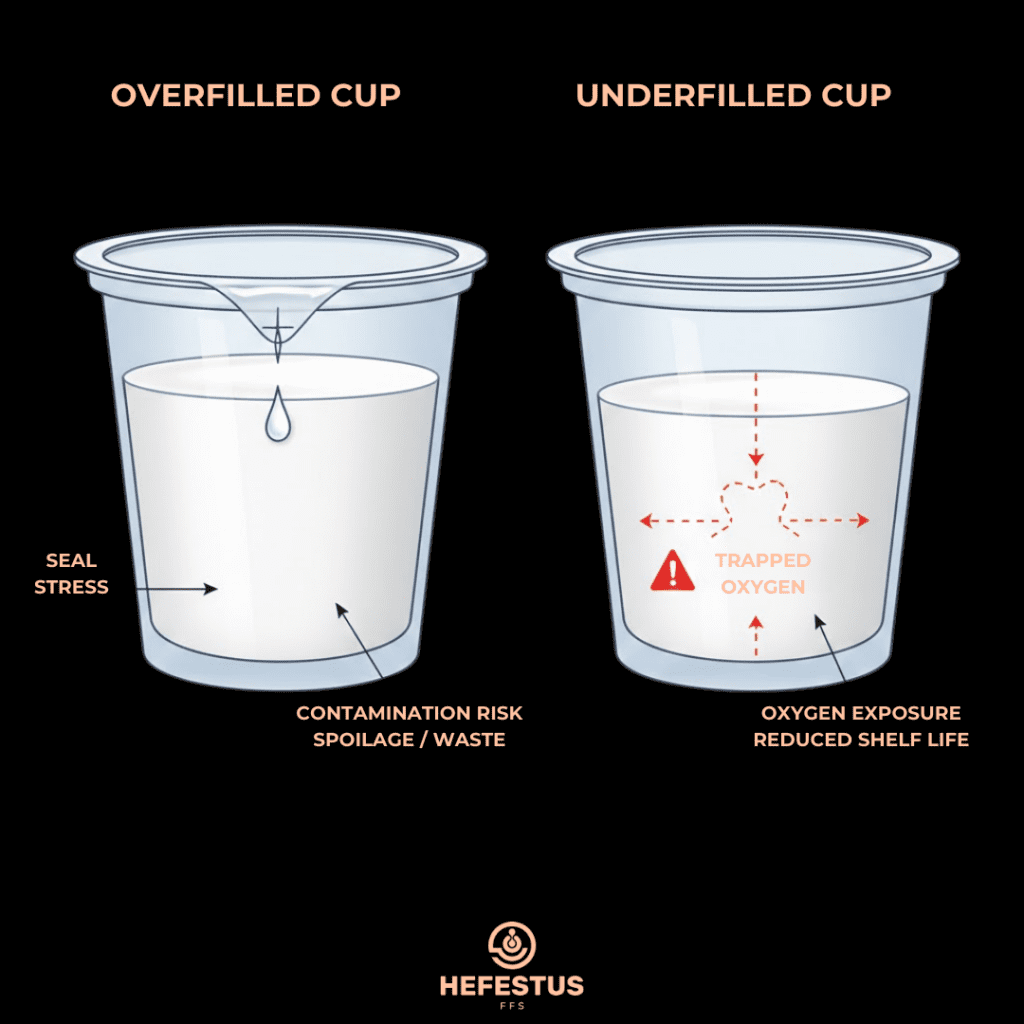

Why Inconsistent Filling and Sealing Kill Shelf Life

Hidden shelf-life killers include:

- Overfilling, which stresses seals and causes micro-leaks

- Underfilling, which traps residual oxygen

- Manual or semi-automatic systems, where operator variability creates inconsistency

Many dairy producers chase better films or containers while ignoring the real issue: process variation upstream.

Trend #2 – Automation Replacing Manual and Semi-Automatic Dairy Packaging

Labor Shortages Are Forcing Automation, Not Convenience

Automation isn’t a luxury—it’s risk mitigation.

Manual packaging introduces:

- Long training cycles

- Hygiene variability between operators

- Inconsistent fills and seals

- Higher contamination risk

Across global dairy packaging trends, producers are automating because they can’t afford variability, not because they want flashy equipment.

Integrated Fill & Seal Systems Are Replacing Multi-Machine Lines

Modern dairy plants are consolidating lines to:

- Reduce handoff points

- Minimize contamination risk

- Shrink floor space

- Improve overall equipment effectiveness (OEE)

Integrated fill-and-seal platforms outperform fragmented lines because every transition point is a failure opportunity in dairy.

Trend #3 – Flexibility Across Dairy Formats and Viscosities

One Line, Multiple Products Is Now a Requirement

Today’s dairy portfolio rarely stops at milk or yogurt.

Producers are running:

- Yogurt today, dairy-based sauce tomorrow

- Protein-enriched products

- Plant-dairy blends

- Multiple SKUs and portion sizes

Packaging lines must handle viscosity variation, product switching, and fast changeovers without compromising hygiene or seal quality.

Why Thermoforming FFS Is Gaining Momentum in Dairy

Thermoforming form-fill-seal (FFS) systems are accelerating in dairy because they offer:

- Consistent cup formation

- Precise portion control

- Faster format changeovers

- Better seal repeatability at scale

Compared to preformed containers, thermoforming reduces dependency on upstream suppliers and improves process control—two major forces behind current dairy packaging trends.

Trend #4 – Sustainability Is Shifting From Materials to Efficiency

Less Waste Through Accurate Filling

Overfill is the most overlooked sustainability failure in dairy.

Every extra gram:

- Increases ingredient waste

- Stresses seals

- Inflates cost per unit

- Undermines sustainability claims

True sustainability starts with dosing accuracy, not recycled messaging.

Energy and Material Reduction Through Compact Automation

Efficiency-driven sustainability includes:

- Smaller equipment footprints

- Fewer conveyors

- Reduced rework and scrap

- Lower energy consumption per unit

Across dairy packaging market trends, sustainability leaders are improving process efficiency first, then materials.

Trend #5 – Hygiene, Compliance, and Cleanability Are Non-Negotiable

Dairy Regulations Are Tightening, Not Loosening

Global dairy producers face:

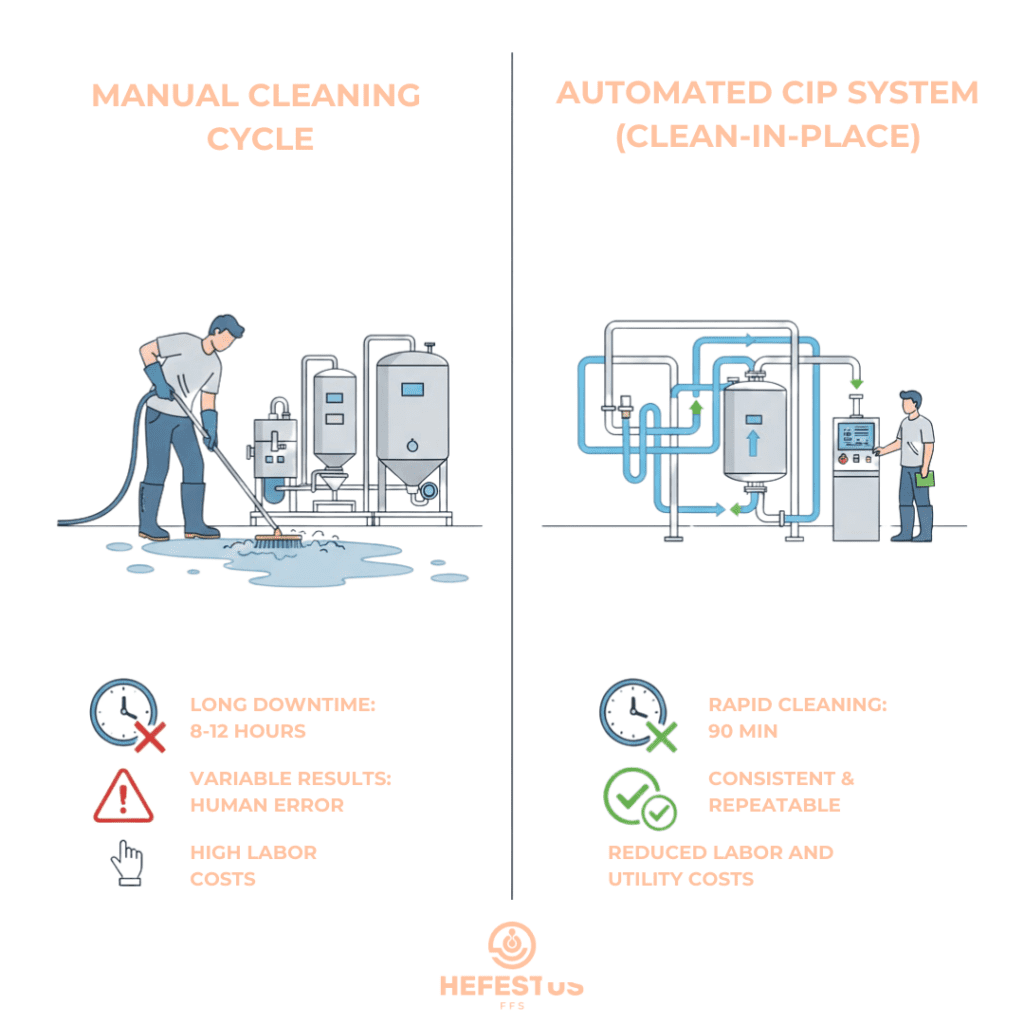

- Stricter clean-in-place (CIP) expectations

- Increased scrutiny on cross-contamination

- Higher penalties for food safety failures

Packaging systems must support fast, repeatable sanitation, not slow manual cleaning.

Why Hygienic Machine Design Is Becoming a Purchase Decider

Equipment buyers are prioritizing:

- Stainless steel construction

- Minimal crevices and exposed fasteners

- Tool-less access for cleaning

- Shorter sanitation cycles

Hygienic design is no longer optional—it’s central to competitive dairy packaging trends.

What These Dairy Packaging Trends Mean for Equipment Selection

Dairy packaging trends ultimately show up in one place: equipment choice. The right system protects shelf life, reduces labor dependency, and scales with demand. The wrong one locks in waste and limits growth.

When Integrated Fill & Seal Systems Make More Sense Than Standalone Fillers

Integrated fill-and-seal systems are the better option when consistency and hygiene matter more than short-term flexibility.

They reduce oxygen exposure and contamination risk by eliminating handoffs between filling and sealing. They also perform better in labor-constrained environments, where manual handling and operator variability introduce shelf-life and quality risk.

Best fit: operations where shelf life, hygiene, and repeatability are non-negotiable.

When Thermoforming FFS Is the Better Long-Term Choice

Thermoforming FFS becomes the stronger choice when product mix, portion sizes, or SKUs are expected to change over time.

Because containers are formed in-line, thermoforming improves dimensional consistency, supports tighter portion control, and enables faster format changes. It also provides more headroom for future scalability compared to preformed container systems.

Best fit: producers planning growth, SKU expansion, or frequent changeovers.

When MAP Becomes Mandatory, Not Optional

Modified Atmosphere Packaging becomes essential as distribution routes lengthen, product value increases, or shelf-life tolerance tightens.

Refrigeration alone can’t manage oxygen exposure at scale. MAP adds a controlled internal environment that protects product quality and reduces spoilage risk across extended logistics.

Best fit: premium products, wider distribution, or stricter retailer shelf-life requirements.

Key takeaway:

The smartest dairy producers treat equipment selection as a system decision, not a machine purchase.

Preparing Your Dairy Line for the Next 5 Years

Most dairy packaging failures don’t come from bad products—they come from lines that were designed for yesterday’s volumes, formats, and labor realities. Preparing for the next five years means stress-testing your packaging system against growth, complexity, and tighter shelf-life expectations before those pressures arrive.

Questions Dairy Producers Should Be Asking Now

Before investing in new equipment or expanding production, dairy producers need to pressure-test their current setup with questions that reveal hidden constraints:

- Can my current line support MAP later, or would it require a full redesign?

- How hard is changeover—really—once labor variability and sanitation time are included?

- What’s my true cost per unit after accounting for overfill, waste, rework, and downtime?

These questions expose whether a line is future-ready—or quietly limiting growth.

Automation as a Growth Enabler, Not a Cost

Automation is often framed as a capital expense, but in modern dairy operations it functions as a growth multiplier. Well-designed automated systems reduce dependence on labor, stabilize quality, and allow producers to scale without increasing operational risk.

Automation enables:

- Scaling without adding labor

- Consistent quality across volumes

- Faster expansion into new markets

- Lower risk per unit produced

This is why automation now sits at the center of modern dairy packaging trends—not as an efficiency upgrade, but as a foundation for sustainable growth.

Final Thoughts: Dairy Packaging Trends Are Process-Driven Now

The most important dairy packaging trends are no longer about materials or marketing claims. They’re about process control. Shelf life is won or lost through accurate filling, reliable sealing, and consistent atmosphere management—long before a package reaches the shelf.

As distribution expands and labor becomes less predictable, producers who invest in integrated, hygienic, and scalable packaging systems will outperform those relying on patchwork solutions. The future belongs to operations that design for shelf life first and scale without adding risk.

Want to go deeper? Share this guide with your team or explore how automation-ready systems can future-proof dairy operations.