How Ground Meat Is Packaged: Chubs, Trays, MAP, and Vacuum Packs

Ground meat is a staple in kitchens around the world, and how it is packaged plays a critical role in maintaining freshness, safety, and consumer appeal. Modern meat processing relies on a variety of packaging formats, each designed for specific use cases and storage conditions.

Understanding these packaging types is essential for producers, retailers, and foodservice providers alike. For manufacturers, using a reliable ground meat packaging machine from Hefestus ensures consistent, high-quality packaging across all formats.

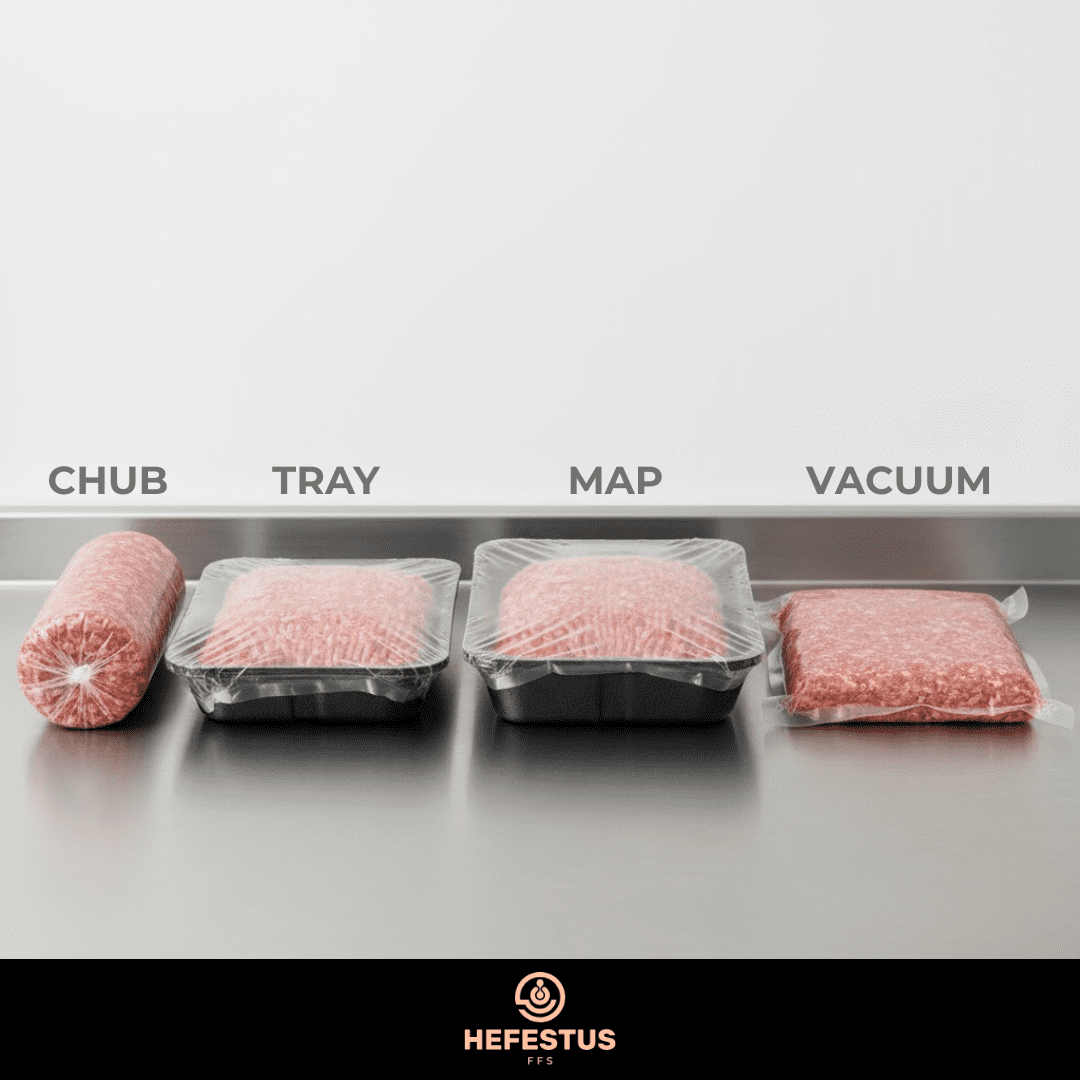

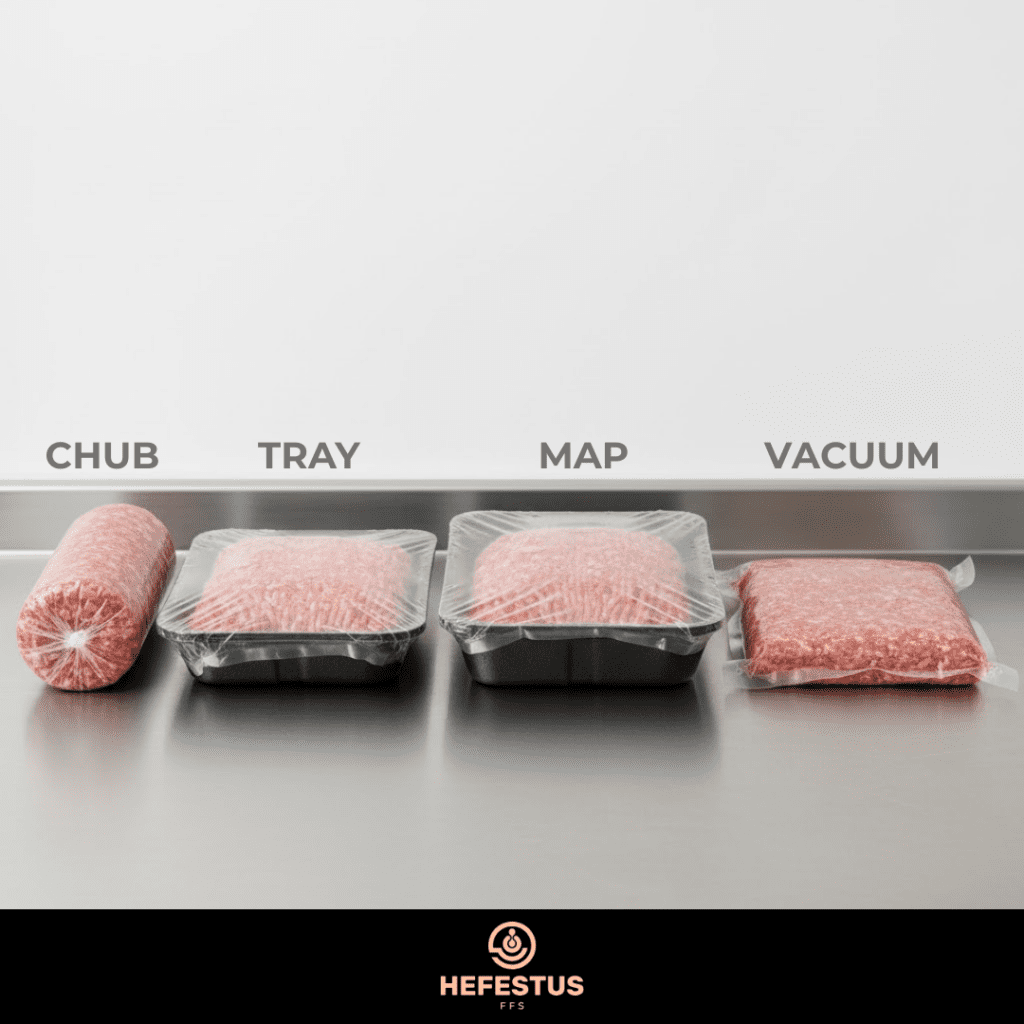

Chub Packaging

Chub packaging is one of the most common formats for ground meat, especially for bulk use in foodservice and retail. In this method, ground meat is tightly packed into cylindrical tubes, or “chubs,” typically made of plastic film. The ends are sealed, creating a uniform package that is easy to handle, store, and transport.

Chubs are ideal for large-volume purchases, such as restaurants, cafeterias, or family-sized retail packages. They are highly efficient for production because automated packaging machines can fill, seal, and cut chubs rapidly, minimizing waste and maximizing throughput. One of the key benefits of chub packaging is that it provides consistent portioning and helps maintain product shape during storage and freezing.

Tray Packaging

Tray packaging is another widely used format for ground meat, particularly in retail environments. Meat is placed in shallow trays, often made from recyclable plastic or foam, and then covered with a film that can be sealed to maintain freshness. Trays are convenient for single-family purchases and allow consumers to see the product clearly, which can influence buying decisions.

Tray packaging is versatile and can be combined with overwrap films or gas flushing to extend shelf life. Using a packaging machine capable of tray filling and sealing ensures each package is uniform, visually appealing, and protected from contamination. Retailers often favor tray packaging for its stackability and display-friendly format, which helps optimize shelf space.

MAP Packaging

Modified Atmosphere Packaging (MAP) is increasingly popular for ground meat due to its ability to extend freshness and improve product appearance. In MAP, the air inside the package is replaced with a carefully controlled mixture of gases, such as carbon dioxide, nitrogen, and oxygen, to slow microbial growth and oxidation.

MAP packaging is ideal for both retail and foodservice markets, as it allows meat to maintain its bright red color and fresh texture longer than conventional packaging. For producers, combining MAP with a packaging machine ensures precise filling, proper gas ratios, and airtight seals, which are crucial for shelf-life extension and product safety. This packaging type also supports clean-label products by reducing the need for chemical preservatives.

Vacuum Packaging

Vacuum packaging is another key method for ground meat, especially for long-term storage or freezing. In this format, all air is removed from the package before sealing, creating a vacuum that prevents microbial growth and oxidation. Vacuum packs are particularly effective for bulk or subscription-based products that need extended storage life.

Vacuum packaging not only preserves freshness but also protects the product during shipping and handling. Using a specialized packaging machine designed for vacuum sealing ensures a consistent vacuum level, proper sealing, and minimal air pockets, which is essential for product safety and quality.

Choosing the Right Packaging Method

Selecting the most suitable packaging method for ground meat requires careful consideration of product type, market demands, and production capabilities. The following factors can help guide this decision:

Consider market and distribution needs

The choice of packaging format depends on several factors, including the target market, shelf-life requirements, and distribution method. Chubs are excellent for bulk use and cost efficiency, trays are preferred for retail display and portion control, MAP packages extend freshness and appeal, and vacuum packs are ideal for long-term storage.

Consumer preferences and regulatory considerations

Producers also need to consider consumer preferences, regulatory requirements, and sustainability. Recyclable tray films or biodegradable chub casings can appeal to environmentally conscious buyers, while packaging that supports MAP or vacuum sealing helps meet food safety standards and compliance requirements.

Equipment flexibility

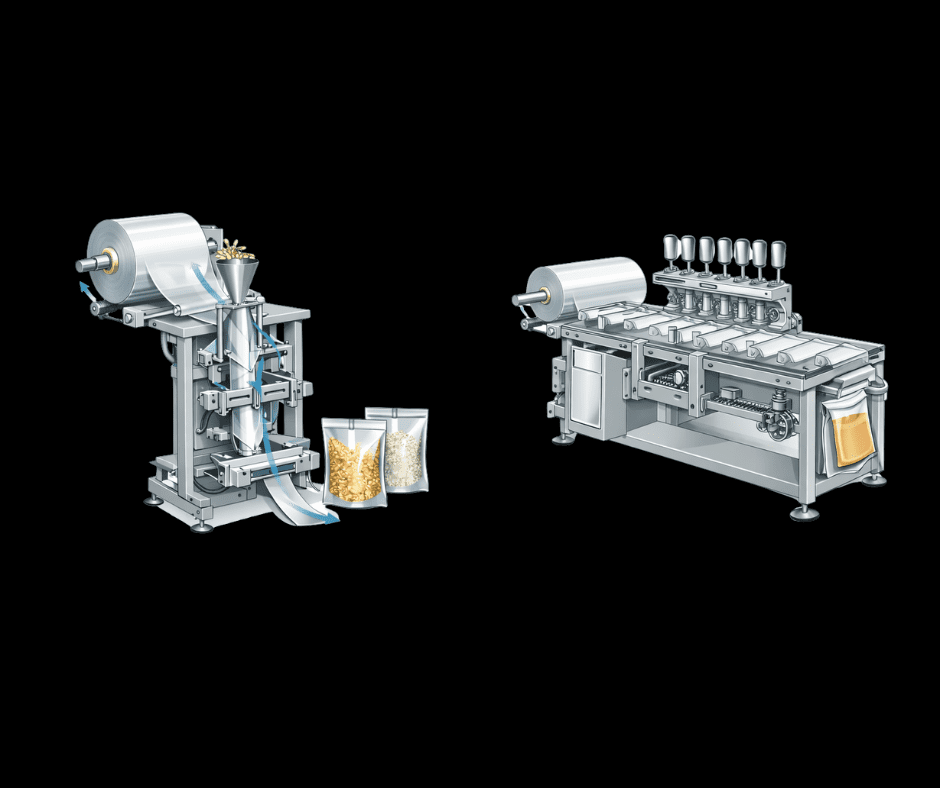

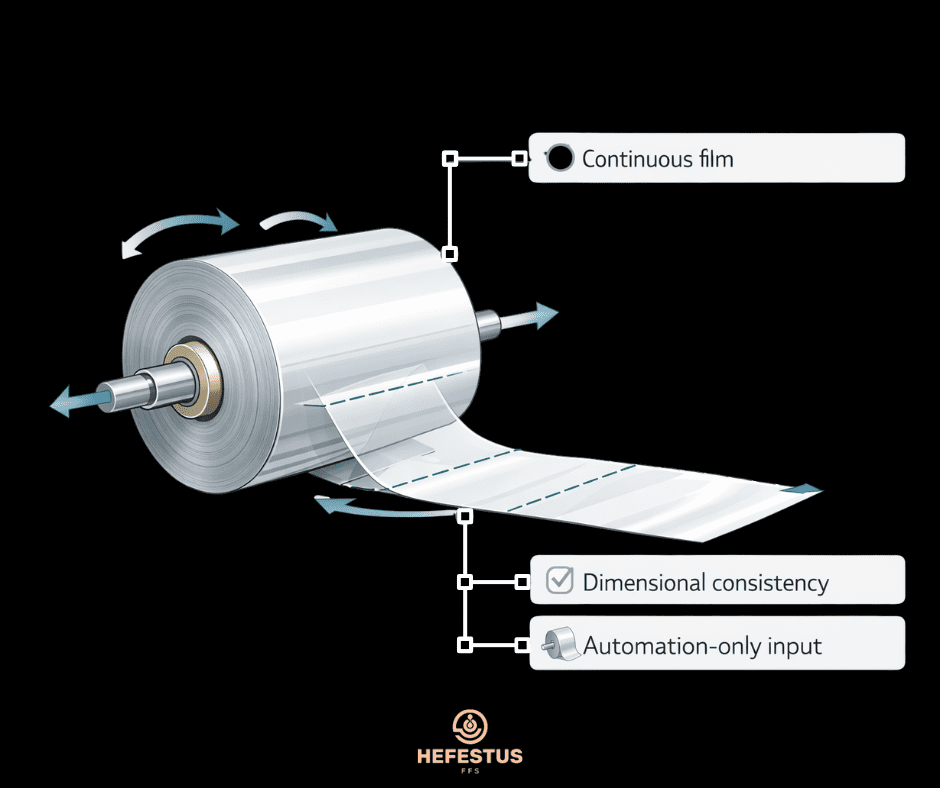

A versatile packaging machine can handle multiple formats, allowing producers to adapt quickly to changing market demands without investing in separate equipment for each packaging type. This flexibility helps maximize efficiency, reduce downtime, and maintain consistent product quality across all formats.

Benefits of Automated Ground Meat Packaging

Investing in automated packaging solutions brings multiple advantages to meat processors:

- Consistency and accuracy: Machines ensure uniform portioning, weight control, and seal integrity, reducing errors common in manual packaging.

- Improved shelf life: MAP and vacuum packaging technologies preserve freshness longer, reducing waste and improving customer satisfaction.

- Efficiency and speed: Automated lines fill, seal, and label packages quickly, supporting high-volume production.

- Safety and hygiene: Minimizing manual handling reduces the risk of contamination, ensuring compliance with food safety standards.

- Flexibility: Modern machines can switch between chubs, trays, MAP, or vacuum packs, supporting diverse product lines with minimal downtime.

By combining a meat packaging machine with the right packaging strategy, processors can ensure product quality, optimize production, and meet market demands efficiently.

Conclusion

Packaging plays a critical role in the ground meat industry, affecting freshness, shelf life, appearance, and consumer appeal. From chubs and trays to MAP and vacuum packs, each format serves a specific purpose and market segment.

For manufacturers, investing in a reliable ground meat machine ensures consistency, efficiency, and high-quality output across all packaging types. Understanding the strengths and considerations of each packaging method allows producers to make informed decisions, reduce waste, improve safety, and ultimately deliver fresh, appealing products to consumers.