How to Infuse Pre-Rolls: Complete Production Guide

If you’re looking to level up your pre-roll operation, introducing infused SKUs is one of the best ways to do it. Consumer demand is moving toward higher-potency, flavor-forward pre-rolls, and infused options now make up a major share of total category sales.

But bringing concentrates into your workflow isn’t simple. Infusion adds extra steps, new variables, and more opportunities for waste. It creates questions every operator eventually runs into, like:

- “How do we keep labor manageable?”

- “How do we stay consistent from batch to batch?”

- “What’s the most efficient way to add infusions without shrinking margins?”

This guide walks you through the main infusion methods used across the industry, where each one tends to help or create issues, and how pre-roll automation can help you scale without sacrificing quality or efficiency.

Why Infused Pre-Rolls Are Taking Over the Market

Infused pre-rolls have quickly gone from niche to mainstream, now representing roughly 40-45% of all pre-roll sales in the major U.S. markets.

In 2023 alone, the category generated an estimated $1.25 billion in sales, easily surpassing single-strain and traditional hybrid pre-rolls. In California, infused joints now account for roughly 66% of all pre-roll transactions.

Infused pre-roll popularity is also taking international markets by storm. In Canada, infused pre-rolls saw more than 1,400% growth in just a single year, jumping from 6.2% to 30% total market share.

For consumers, the popularity of infused pre-rolls makes sense. They offer higher potency, flavor variety, and a dab-like experience without needing rigs or torches. Experienced users appreciate the strength; newer consumers appreciate the accessibility.

Altogether, these benefits drive sales to premium SKUs that command 1.2-2x more than traditional pre-rolls, and encourage repeat purchases when quality is consistent.

For operators, the category opens the market to higher-margin SKUs and more product variety. Of course, they also require higher production demands, including tighter standards for dosing accuracy, burn consistency, and visual quality.

If your catalog doesn’t include infused SKUs yet, you’re at risk of losing shelf space to competitors that are already capitalizing on the fastest-expanding segment in the category.

The next step is understanding how infused pre-rolls are made, because the method you choose has a major impact on consistency, cost, and long-term scalability.

How to Infuse Pre-Rolls

In the world of infused pre-rolls, there’s not just one way to manufacture them; there are several methods, each with its own advantages and disadvantages for operators. And because the way you infuse pre-rolls affects consistency and cost, it’s important to understand the differences.

Beyond consistency and cost, choosing the right method early on can help you avoid major headaches as you scale. To help, we’ve outlined the top ways to infuse pre-rolls and how each one affects scaling, consistency, and workflow.

Post-Roll Injection (Core Infusion)

The first type of pre-roll infusion method works just as it sounds. After the pre-roll is filled, the concentrate (distillate, live resin, rosin, etc.) is injected through either the filter end or the tip.

Hand-injecting gives you the most controlled results, providing consumers with an even burn, consistent potency per joint, and a clean appearance that doesn’t show on the exterior of the paper or cone.

The core infusion method is one of the most common for mid- to large-scale operators because it’s easily repeatable and measurable, with dosing that can be calibrated by volume or weight. It does, however, rely on evenly packed joints for the best results.

Without uniform cone density, this method can cause blockages or pooling near the base due to unevenly packed joints. That’s just one challenge you’ll need to watch for, along with maintaining the extract’s temperature and viscosity to prevent clogging and ensure smooth injections.

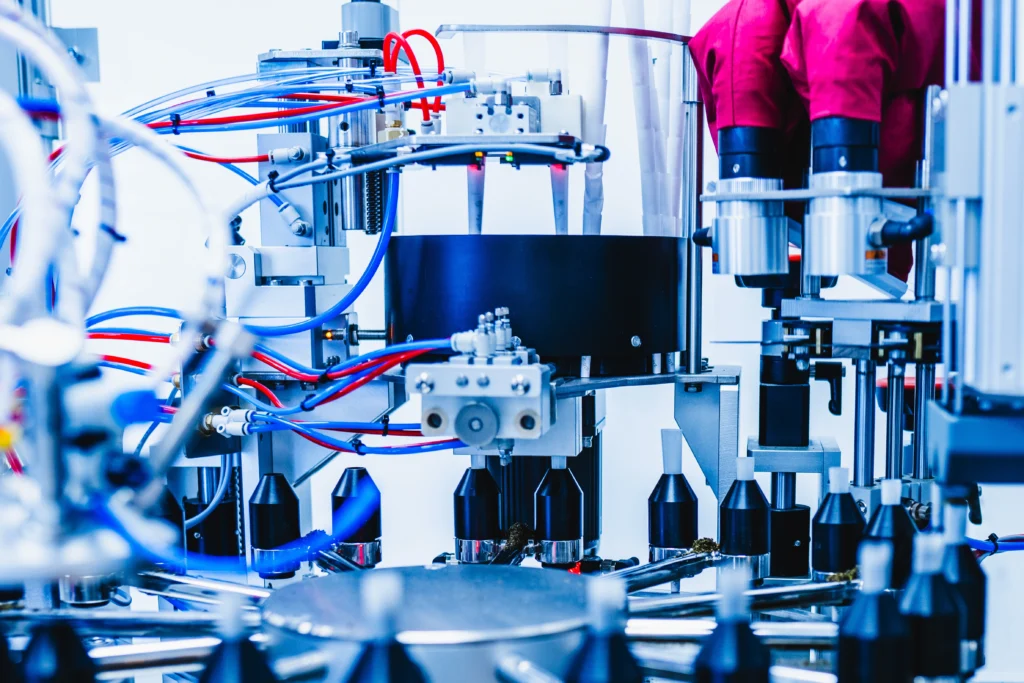

This method is also very automation-friendly, using advanced needle dosing systems that deliver precision and higher throughput. These systems can be easily integrated into existing production lines to transition from non-infused to infused seamlessly.

Pre-Mix Infusion (Blended Flower + Concentrate)

The next way to add infusion to your workflows is through the pre-mix infusion method. This takes place before the fill, when the concentrate or extract is mixed into the milled flower to create a uniform, bulk-infused blend.

This method is usually chosen by early-stage operators or brands who want to experiment with infused SKUs before investing in new equipment. While it provides an even distribution of concentrate, the sticky material can be more challenging to handle during cone filling.

Anytime you’re working with excess amounts of concentrates, things can get messy fast. Excess extract can gum up grinders, clog cone fillers, or cause airflow issues in the finished product.

Consistency is everything here, and it depends heavily on batch control. This means making sure the ratio of concentrate to flower is just right, the mixing duration is the same for each one, and the temperature remains stable for optimal filling conditions.

If you’re considering this method, it’s also worth nothing that it’s harder to scale cleanly for larger runs. It’s also not as automation-friendly as core infusion, though it can be done with certain mixers or augers.

Surface Coating (Kief or Oil-Dipped Pre-Rolls)

Another popular infused product you’ll find on shelves today is the surface-coated pre-roll, including the familiar kief- and oil-dipped styles. Instead of infusing the concentrate on the inside of the joint, this method focuses on the exterior.

After the pre-rolls are filled, the concentrate or oil is rolled, brushed, or sprayed onto the outside of the joint. This step is often followed by dusting the joint in kief, giving it that “tarantula” look and a premium, craft-style finish.

Immediately, the kief coating elevates the pre-roll from an everyday SKU to a showpiece, making it especially appealing to consumers seeking premium or craft SKUs. This product type is visually distinct compared to others, offering high retail appeal and strong shelf differentiation.

While surface-coated joints can command higher price points, the tradeoff is throughput. Each pre-roll requires manual handling or low-speed coating automation, which limits how efficiently you can scale.

As with any infusion type, there are drawbacks. These joints are more prone to uneven burns due to the manual work required, and they can create significant product loss from dripping oil or concentrate buildup on equipment.

Because burn consistency is so important for consumers, it’s a significant drawback that you’ll have to consider. Overall, this method is best suited for small or craft batches, limited releases, or promotional drops, not high-volume, continuous production.

The Hidden Costs of Manual Infusion

Like any workflow, there are hidden costs that come with manual infusion, and they add up fast once you start working with sticky concentrates.

First, manual dosing requires multiple human touches for every SKU. Over time, this creates bottlenecks, and throughput will vary significantly depending on operator speed and fatigue, making consistent output difficult to maintain.

Quality can slip for the same reason. The painstaking process of filling each pre-roll by hand becomes cumbersome over a normal shift, leading to uneven milligram per joint results that may require rework or result in product loss. As pricey as extract can be, it’s not something you’ll want to waste regularly.

Even more, the consistency of your fills affects the burn rate. Uneven injections, or poor mixing and blending, are more likely to cause burn issues, such as canoeing. To retain customer loyalty, poorly injected products often need to be tossed, wasting material again.

Another hidden cost is clean-up. Concentrates are notoriously sticky and tend to stick to tools, gloves, and trays, which leads to additional product loss and higher production costs. More cleaning also slows changeovers and adds downtime

From start to finish, manual infusion of joints negatively affects the final results and overall yield. With handwritten or manual logs, you’ll lose the ability to track, trace, and verify batches when issues arise later, which makes it challenging to track real production costs.

Ready to Scale? Here’s Where Automation Changes Everything

As you can tell, while manual infusions do get the job done, scaling requires consistency, speed, and predictable costs – all three things that become harder to maintain by hand.

That’s where automation comes in. Automated infused processes help remove the most common bottlenecks and give you measurable improvements across output and quality:

- Automation eliminates dosing errors and ensures every pre-roll gets the same amount of concentrate, reducing failed COAs and rework.

- Systems like AuraX can infuse hundreds of pre-rolls per hour with consistent results, increasing output without adding labor.

- Controlled dosing reduces overfill, spillage, and leftover concentrate, improving overall yield.

- Automated workflows deliver uniform burn, appearance, and potency, helping brands strengthen consumer trust.

- Automated systems adapt quickly to different viscosities and product types, reducing downtime between SKUs.

- Built-in data capture simplifies QA, compliance, and batch traceability for smoother audits.

- Automation frees up staff for higher-value tasks like packaging, QA, or R&D.

- With better yield, less waste, and steadier output, automation helps protect margins and makes scaling more predictable.

Spotlight on AuraX

If you want to enter the infused pre-roll space and scale quickly, or already have high-volume demand, automation is inevitable. Equipment like the AuraX is what top pre-roll brands use to produce infused SKUs at scale.

The AuraX is our flagship automated pre-roll system, which produces 36 pre-rolls per minute, or approximately 1,500 per hour. It can run multiple cone sizes, blunt-style formats, and infused SKUs, thanks to its Smart Cut VFiQ system.

By automating these steps, you can maintain consistency while cutting labor costs by up to 90% – a win-win for MSOs, co-packers, and operators pushing toward higher throughput.

Operators choose the AuraX not only for its consistent quality and speed, but also for its ability to handle sticky materials, like live rosin, bubble hash, or infused blends without clogging or downtime.

You can also switch between SKUs with minimal changeover, and the included 5 days of on-site training prepares your team with customized SOPs, so you’re ready to run production immediately.

For consumers, every joint finishes with a consistent weight and density, along with the clean Dutch crown tip, giving it a premium, hand-rolled look and burn – without the cost of the manual labor required to achieve it.

On the operator side, the AuraX goes beyond filling and infusing. With built-in weighing and packaging add-ons, workflows can be streamlined, reducing post-fill steps for quality assurance and compliance.

And if it feels financially out of reach, Hefestus offers flexible financing options designed for cannabis operators, including $0 down.

All in all, the proof is in the output: after purchasing the AuraX, Seed & Smith in Colorado now produces up to 15,000 pre-rolls a day with just two operators.

Conclusion: How to Infuse Pre-Rolls The Right Way

As one of the fastest-growing product categories in cannabis, infused pre-rolls are becoming essential for emerging and established brands.

Now that you know the basics of the main infusion methods, you can choose the one that best fits your operation and its current stage.

While manual infusion works for small-scale runs, it eventually limits consistency, throughput, and profitability. That’s why teams who are serious about scaling are turning to automation to infuse pre-rolls efficiently while preserving product quality.

The AuraX is the industry’s most versatile system, built to handle a variety of infused formats with precision and ease. It gives operators the control, scalability, and ROI they need to stay competitive as the category grows.

Ready to explore the future of infused pre-rolls?

Start with efficiency, precision, and innovation by learning more about automation and the Hefestus AuraX today.

How to Infuse Pre-Rolls: Frequently Asked Questions

Here are answers to the most common questions about infused pre-rolls.

What’s the Best Concentrate for Infused Pre-Rolls?

There’s no single best option. Live rosin delivers the strongest terpene profile, while live resin and diamonds offer higher potency at lower cost. What matters most is choosing a concentrate with predictable viscosity and melt behavior so dosing can be consistent.

Can You Automate Pre-Roll Infusion?

Yes. Systems like the AuraX automate core injection, spray/mix, and surface coating methods. Automation helps eliminate ratio drift, clumping, and airflow issues that are almost unavoidable with manual infusion.

What’s the Most Efficient Infusion Method?

Post-roll injection is generally the most efficient because it minimizes waste and keeps dosing consistent. Spray infusion is fastest for large runs, and kief coating boosts visual appeal, but both require more manual handling.

How to Make Diamond-Infused Pre-Rolls?

Finely grind diamonds or melt them into a syrup, then mix with milled flower so they melt evenly during combustion. Automated metering keeps potency uniform and helps avoid hot spots or burn issues.