How to Pack A Pre-Roll Cone

Packing a single pre-roll is simple. But scaling the same process to thousands per day without losing consistency is not.

If you’re a pre-roll producer looking to increase your production volume to meet demand without sacrificing quality, this guide breaks down what the process looks like.

We’ll cover how to pack pre-roll cones properly, then walk through the workflows that make scaling possible.

How to Pack a Pre-Roll Cone by Hand

To pack a pre-roll cone by hand, there are several main steps:

- Grind the Material: Begin by grinding your material to a consistent, medium-fine texture. Uniform particle size is critical for proper airflow and structural integrity inside the cone. Avoid over-grinding, as excess fines can restrict airflow and compromise burn consistency.

- Fill the Cone: Fill the cone incrementally, adding material in small amounts while keeping the cone upright. Lightly tap the cone during filling to allow the material to settle evenly without compression. Controlled fill density ensures reliable airflow and an even burn profile.

- Close the Pre-Roll: Once filled, leave sufficient space at the top to properly finish the pre-roll. Twist the paper or fold the edges down evenly to secure the contents. A clean, consistent closure helps maintain shape, protects the fill, and prepares the pre-roll for storage or use.

As you can see, the cone packing process is pretty straightforward if you’re packing pre-rolls for home use or at low volumes for a smaller operation. But hand-packing processes aren’t suitable for large-scale production because of the high labor costs and quality assurance issues that would crop up.

Why Hand Packing Won’t Scale in Your Facility

In large-scale settings, it’s nearly impossible to scale hand packing, regardless of the product. Pre-rolls are no exception. First and foremost, hand packing requires multiple operators, which quickly drives up labor costs.

And even with a whole team, output is significantly limited compared to what automated pre-roll equipment can achieve.

Beyond the number of workers you’ll need, human error is inherent to hand packing. When scaling depends on consistent, compliant products, manual processes put your facility at risk of inaccuracies and product loss.

Pack density will vary from operator to operator, leading to inconsistent product quality. Whether it’s airflow issues or canoeing, consumer complaints pile up while sales start to slow.

Ultimately, labor cost per unit does not decrease with volume, making it virtually impossible to scale hand packing profitably.

Step-by-Step: How to Pack a Pre-Roll Cone on the Production Floor

To keep airflow, weight accuracy, throughput, and quality control consistent, here’s a typical pre-roll cone packing workflow, step by step.

Prepare Your Material

First, it’s crucial to prepare your material as uniformly as possible to achieve consistent results. That starts with controlling the flower grind size and keeping moisture levels consistent from batch to batch.

One of the biggest challenges at this stage is removing stems so they don’t puncture the paper later in the process. Material prep sets the foundation for the joint’s density, airflow, and downstream efficiency, making proper handling essential.

Inspect and Stage Your Cones

Before filling your cones, inspect the exterior for any flaws and prepare them (or “stage” them) for filling. Check the cones for damage, misaligned crutches, or loose filters and discard any rejects.

Next, stage the cones in trays or holders so operators can work efficiently instead of fumbling with each one individually for each fill. Because uniformity supports better fill consistency, this is another step you won’t want to overlook.

Fill to Target Weight

Next, fill each cone to its target weight using measured portions based on the SKU’s specifications (e.g., 0.5 g, 1 g). Dialing in fill weights is critical, as it affects both profitability and compliance.

Even minor deviations can impact regulatory test results or add up over time, shrinking margins. Overfill is where many operations lose money, which is why integrating weight-accuracy checks along the line supports long-term profitability.

Set Pack Density

The next step is setting pack density, which is important to get right for burn quality and airflow. To prevent pre-rolls from clogging, avoid overcompaction, as it can negatively affect quality control and consumer retention.

When filling, gently and consistently press or tamp down the material. This helps the material burn more evenly and delivers a better experience for the consumer.

Finish the Joint

After filling, it’s time to finish the joint. At the end of the paper, you can either twist the remaining material or fold it into a Dutch crown, depending on your brand’s SOP.

Keeping this step consistent is recommended, as the joint’s finish affects both appearance and overall customer perception.

Run Weight & Quality Checks

Lastly, spot-check finished units for weight, structure, and density for draw purposes. At this quality checkpoint, document or log the checks to maintain consistency across shifts or identify issues early.

This step is one of the most important for identifying drifts from product standards or SOPs and preventing issues from becoming batch-wide problems.

Common Pitfalls That Hurt Quality and Profitability

To avoid inconsistent quality, high reject rates, slow throughput, and unnecessary labor costs, watch for the following:

Inconsistent Grind or Material Prep

As mentioned earlier, material prep is crucial to maintaining the quality of the end-product. Avoid overly fine material that can clog and causes tight draws, as well as material that is too coarse or contains stems, which can puncture cones and create uneven airflow.

Incorrect or Inconsistent Pack Density

Pack density is another common pitfall when trying to scale quality, profitable products. Overpacking restricts airflow, which often leads to consumer complaints.

Underpacking, on the other hand, causes canoeing and structural failures that turn consumers off and reduce repeat purchases.

Weight Inconsistencies

Not only can overfilling lead to compliance issues due to off-weight units, but it can affect your bottom line, too. In simple terms, overfilling is giving away product, which shrinks your overall margins.

Poor Cone Quality or Handling

We stress the inspection and staging during the pre-roll packing process to avoid poor cone quality and prevent improper handling. This step weeds out damaged filters, bent papers, and collapsed cones before handling issues turn into increasing rejects.

Inconsistent Finishing

The finish of your joint doesn’t just seal it; it affects the airflow and its overall appearance. Whether using a twist or a Dutch crown fold, keeping a consistent finish prevents unpredictable burn performance and improves appearance.

Infused SKUs Causing Variability

When infusing pre-rolls, the stickiness of the material creates additional challenges for even distribution and optimal airflow. Without uniformity, production lines create more rework and higher reject rates.

Drift Between Shifts or Operators

It’s crucial to prevent variability or drift between shifts or operators to maintain consistent SKUs that consumers re-purchase. The differences in techniques lead to inconsistent products, and without standardized SOPs, that variability widens.

How Pre-Roll Automation Streamlines Cone Packing

When hand-packing cones, results vary widely depending on who is working, how long they’ve been on shift, and how consistent their technique is. That variability shows up in pack density, airflow, weight, and finishing.

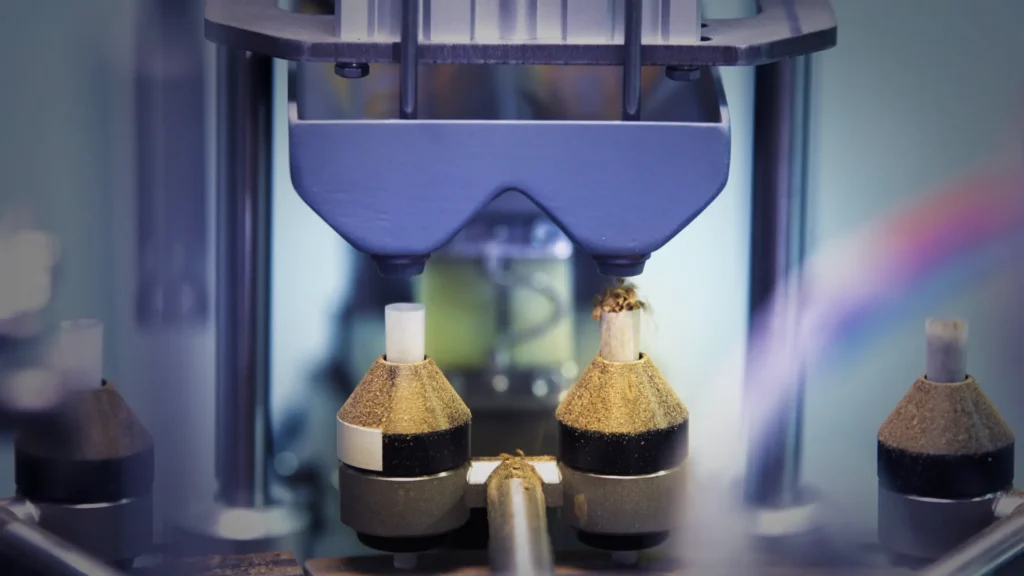

Automation removes the uncertainty of irregular cone packing by transforming your workflow into a controlled, precise, and repeatable process across every shift.

With an automated system like the Hefestus AuraX, weight accuracy is no longer a constant battle. You get precise, repeatable fills that reduce overfill loss, keep you within compliance, and cut down on rework that slows your line and eats into margins.

When one operator can oversee thousands of cones per hour, you can keep costs predictable while still increasing throughput. This is the key to scaling output without scaling labor.

Infused SKUs introduce even more risk when packed manually. Sticky, resin-heavy material can clump, shift, or restrict airflow, leading to tight draws and uneven burns. Filling with automation uses consistent control to improve distribution and preserve airflow.

By standardizing filling and finishing, automation reduces reject rates and material waste. Integrated checks catch issues earlier, before defects reach packaging or distribution.

Most importantly, automation gives you predictability. Your operations become easier to forecast, scale, and manage as your team shifts from hand packing to higher-value work such as quality control and material preparation.

Conclusion: How to Pack a Pre-Roll Cone

Packing a pre-roll cone is easy when it’s for yourself at home – or for a smaller production operation. But packing pre-rolls at greater scale and ensuring every unit is consistent is the real challenge.

In this guide, you’ve learned about the typical workflow for packing pre-rolls in a large-scale production setting and how common breakdowns negatively affect quality and margin.

You’ve also learned how automation streamlines the workflow from fill to finish, for more predictable results with less labor.

If you’re ready to maximize volume while maintaining consistent quality, learn how the AuraX supports high-volume production.

How to Pack a Pre-Roll Cone: Frequently Asked Questions

Here are answers to the most common questions operators have about packing pre-roll cones at scale.

Do You Pack a Cone Tight or Loose?

You should pack a cone firmly but not too compressed, striking a balance between tight and loose. You’ll want enough density for structure and an even burn, while still leaving a clean airflow path for a smooth draw.

How Can I Avoid Overpacking a Cone?

You can avoid overpacking a cone by avoiding overcompression of the material. Focus on consistent fill depth and light, controlled tamping to ensure the material settles naturally without restricting airflow.

How Do You Avoid Air Pockets in a Joint?

You can prevent air pockets in a joint by filling the material evenly and avoiding internal bridges in the cone. Fill the cone gradually, letting the material settle between fills to prevent internal gaps and uneven density.

How Do I Dutch Fold a Joint?

To Dutch fold a joint, gently tuck the excess paper inward in a spiral at the tip. This keeps material contained while maintaining airflow at the start of the burn.