Packaging Trends for Salad Dressings in 2026

The salad dressing market has seen steady growth over the past few years, driven by consumer demand for healthier meals, convenience, and clean-label products. As the market evolves, packaging trends play a critical role in attracting buyers, maintaining product freshness, and supporting brand differentiation.

For food manufacturers and processors, staying ahead of these trends requires understanding the latest packaging innovations and selecting the right equipment, such as a salad dressing packaging machine, to meet production needs efficiently.

Sustainable and Eco-Friendly Packaging

Sustainability continues to be a top priority for both consumers and brands in 2026. Salad dressings are increasingly packaged in recyclable, biodegradable, or compostable containers to reduce environmental impact.

Trends to Watch

- Plant-based plastics and glass: Biodegradable plastics and lightweight glass bottles are gaining popularity as alternatives to traditional packaging.

- Minimalist packaging designs: Consumers appreciate reduced packaging material and clean designs that communicate eco-consciousness.

Adopting sustainable packaging not only aligns with consumer expectations but also enhances brand reputation. A modern packaging machine can accommodate these new materials without compromising efficiency or product quality.

Automation and Efficiency in Packaging

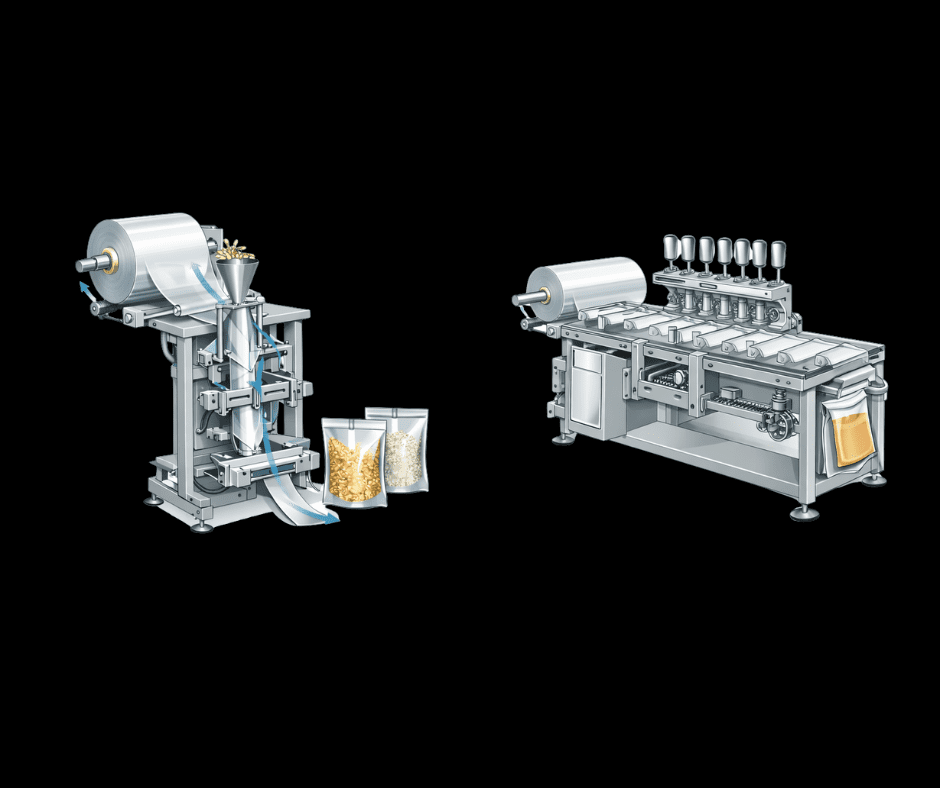

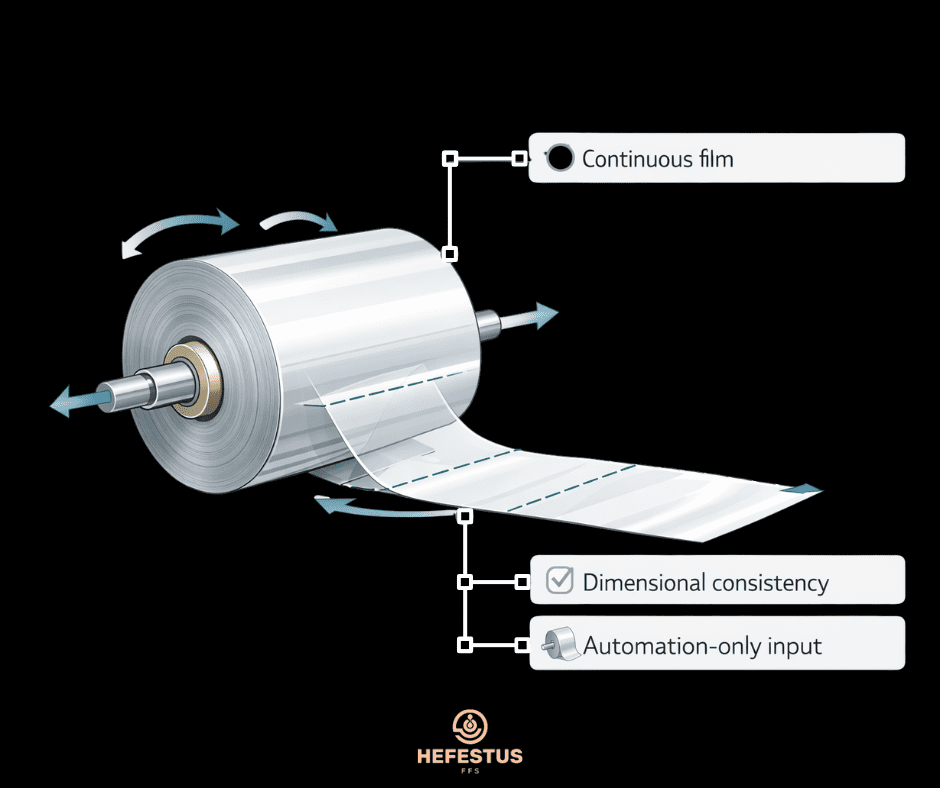

With increasing demand and tighter margins, automation is becoming critical in salad dressing production. Modern packaging lines integrate filling, capping, labeling, and quality inspection in a single workflow, reducing labor costs and minimizing human error.

Manufacturers using automated packaging machines can maintain consistent product quality, speed up production, and scale easily to meet seasonal spikes or market growth.

Portion-Control and Convenience Packaging

Busy lifestyles and on-the-go consumption have fueled demand for single-serve and portion-controlled packaging. Consumers are looking for convenient options that are easy to store, use, and transport.

Popular Formats

- Single-serve cups and sachets: Ideal for lunches, meal kits, and snack boxes.

- Travel-friendly bottles: Small bottles with secure caps that prevent leakage while traveling.

Packaging machines capable of handling small volumes with precision are essential for producing these formats efficiently, ensuring consistency and reducing waste.

Premiumization and Differentiation

In 2026, salad dressings are no longer just functional condiments, they are part of the culinary experience. Consumers are willing to pay more for premium products that offer unique flavors, high-quality ingredients, and visually appealing packaging.

Design considerations

- Clear bottles for product visibility: Transparent containers showcase natural ingredients and textures, enhancing consumer trust.

- Custom labels and branding: Unique labeling, embossing, and shrink sleeves can help your brand stand out on crowded shelves.

A versatile packaging machine can handle various bottle sizes and labeling options, supporting innovation and product differentiation.

Enhanced Shelf Life with Intelligent Packaging

Maintaining freshness and safety is a key concern for refrigerated and ambient salad dressings alike. Packaging technologies in 2026 are increasingly focused on extending shelf life without compromising taste or nutrition.

Technologies to Consider

- Vacuum sealing and air-tight caps: Reduce oxidation and preserve flavor.

- Modified Atmosphere Packaging (MAP): Helps extend freshness for dressings containing natural preservatives or sensitive ingredients.

Using the right packaging machine ensures precise filling and sealing, minimizing contamination and spoilage while maximizing efficiency.

Smart and Interactive Packaging

The rise of smart packaging is reshaping how consumers interact with products. QR codes, augmented reality (AR) experiences, and scannable nutrition info are becoming more common.

Benefits for Salad Dressings

- Consumer engagement: QR codes can provide recipes, pairing ideas, or brand storytelling.

- Traceability and transparency: Interactive labels allow consumers to verify ingredients, sourcing, and production dates.

Manufacturers need packaging equipment that can integrate labeling, coding, and traceability features seamlessly into high-speed production lines.

Customization and Small-Batch Production

Another key trend shaping salad dressing packaging in 2026 is the growing demand for customization and small-batch production.

Consumers are increasingly seeking unique flavors, healthier formulations, and products tailored to specific dietary needs, such as low-sugar, vegan, or keto-friendly dressings.

Trends to Watch

- Limited-edition flavors: Small-batch runs allow brands to experiment with seasonal ingredients or specialty flavors, creating excitement and urgency among consumers.

- Personalized packaging: Custom labeling, flavor combinations, and even personalized messages on bottles can enhance the consumer experience and foster brand loyalty.

- Flexible production lines: With the rise of direct-to-consumer sales and subscription boxes, manufacturers need equipment capable of efficiently handling short runs and frequent changeovers.

Modern packaging machines are designed to support this flexibility, enabling producers to adjust fill volumes, bottle sizes, and labeling setups quickly without sacrificing speed or accuracy.

This trend also allows brands to respond rapidly to market feedback, launch niche products, and cater to smaller retailers or specialty stores that demand differentiated offerings.

Conclusion

As the salad dressing market grows in 2026, manufacturers must adapt to evolving consumer expectations and market trends. Sustainable packaging, convenience formats, premium designs, enhanced shelf life, and smart packaging are key drivers of success. Investing in an automated packaging machine not only streamlines production but also enables your brand to capitalize on these trends efficiently.

By selecting the right packaging strategy and equipment, food producers can ensure their salad dressings remain fresh, visually appealing, and aligned with consumer preferences, ultimately driving sales and brand loyalty in a competitive market.