How To Streamline Your Pre-Roll Production With A Pre Roll Packaging Machine

As convenient and cost-effective as pre-rolls are for consumers, it should come as no surprise that the products are in high demand. In fact, according to Flowhub, a leading cannabis industry research firm, pre-rolls were the fastest-growing category in 2024, with more than 4.1 billion in sales.

Of course, keeping up with that demand is posing challenges for operators at the same time. In today’s market, operators are not only expected to navigate rising demand but also increased labor costs and complex compliance regulations for packaging. That’s why many facilities today are now exploring pre-roll packaging machines to automate processes.

From pre-roll filling to tube labeling and packaging, the rise of the machines is next in line for the market. So, if you’re a current operator who’s struggling, or a new operator looking to start with a strong foundation for growth…this guide to automated pre-roll packaging is for you. Here, we’ll dive deep into the topic by reviewing the real cost of manual packaging, the latest innovations available today, and more.

Keep reading to learn everything you need to know about cannabis pre-roll packing equipment, from the leaders in the industry, and the house of automation themselves, Hefestus.

The Real Cost of Manual Pre-Roll Packaging

If you’re a new operation and not already seeing the downsides of manual pre-roll packaging for yourself, it’s crucial to understand the costs of it first. This way, you can understand just how essential pre-roll automation solutions are to a growing business’s bottom line. In general, four areas of pre-roll production quickly become costly for operators:

- Labor inefficiency: Not only does human labor lead to inefficiencies, which can increase waste and decrease quality, but it can also lead to high staffing costs.

- Inconsistent quality: From seals and labeling to fill and presentation, manual pre-roll packaging can cost operations their reputation due to poor-quality products.

- Non-compliance risk: Human errors can also lead to risks in terms of weight, labeling, and child-resistant features, which can result in costly compliance fines.

- Slower production: Not surprisingly, manual labor is far less efficient, leading to slower production and ultimately limiting scalability.

Why Pre-Rolls Require Specialized Packaging Solutions

The next question you may have is, why do pre-rolls require specialized packaging solutions? At its core, the single product item requires delicate handling to preserve its integrity. That means, when searching for a packaging machine for cannabis pre-rolls, you’ll want to observe just how the piece of equipment handles the pre-rolls, so as not to disturb or damage their true form.

Secondly, like many products in the cannabis industry, pre-rolls are subject to precision in weight for compliance purposes and consumer satisfaction. I.e., customer retention and brand loyalty can be negatively affected if pre-rolls are consistently sold underweight. They also require labeling for consumer safety purposes (and compliance) along with proper sealing, which protects the flower from air and light, thereby preserving its terpenes and natural cannabinoid profiles.

Streamlining packaging with advanced pre-roll packaging machines enables operators to not only meet compliance requirements but also brand requirements. This factor is crucial for maintaining brand consistency and a strong reputation across the thriving cannabis community in your state or market. Not to mention, top-tier packaging equals top-shelf presence in competitive retail markets.

How Pre Roll Packaging Machines Solve the Problem

So, just how can pre-roll brands keep up with consumer demands and the demands of the industry? That’s where pre-roll packaging machines come into the conversation. The innovation of high-speed pre-roll packaging is fueling the growth of businesses across the US by providing efficiency, along with reliability in quality and consistency.

Advanced equipment, like that made by Hefestus, is specifically designed for the cannabis industry to package at a high speed, while also providing consistent seal quality and label accuracy, operators can trust (without the fear of human errors!). As for labor, these machines also require minimal operator intervention, which reduces labor costs while increasing throughput.

Lastly, to optimize pre-roll production, automated pre-roll packaging equipment streamlines the compliance-ready features required by state markets, such as child-resistant features, tamper-evident packaging, and proper labeling, with less margin for error.

Key Features to Look for in a Pre-roll Packaging Machine

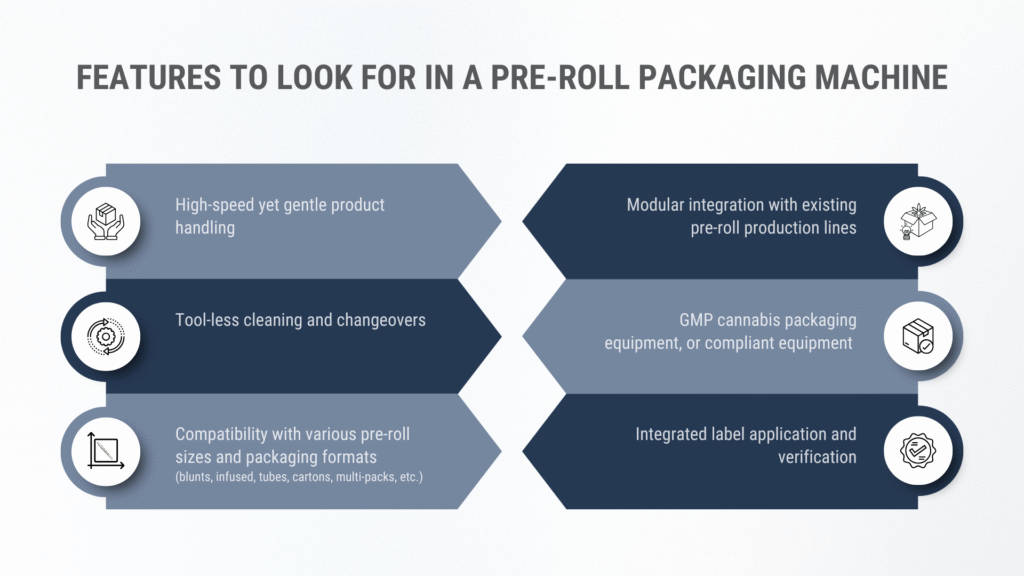

Of course, it’s also important to understand that not all pre-roll packaging machines can be treated equally. Some are standard pieces of equipment that are retrofitted to work for pre-rolls, while others are explicitly designed with cannabis prerolls in mind. If you’re looking to invest in cannabis pre-roll packing equipment that’ll keep downtime to a minimum and maintain your product’s quality, here are the top key features to seek out:

- High-speed yet gentle product handling

- Modular integration with existing pre-roll production lines

- Tool-less cleaning and changeovers

- GMP cannabis packaging equipment, or compliant equipment

- Compatibility with various pre-roll sizes and packaging formats (blunts, infused, tubes, cartons, multi-packs, etc.)

- Integrated label application and verification

These features ensure that operators gain the advantages of pre-roll automation solutions, rather than creating more problems for themselves with a piece of equipment that fails to deliver the desired results or does so insufficiently.

Real-World Production Gains and ROI

Finally, it’s also vital to know that the investment you make into your operation today can turn into the real-world gains of tomorrow and the future. While pre-roll packaging machines are a hefty up-front investment, their ROI can pay for itself more quickly than you think. First and foremost, operators will begin saving on labor and overhead, nearly immediately.

Secondly, when you optimize pre-roll production with automated packaging, your products will hit the shelves faster. This helps meet the demand of retailers while building trusted relationships, as your operation is more likely to meet deadlines and avoid missing fulfillment periods, thanks to reliable equipment and minimal downtime on the line.

A more long-term sign of production gains and ROI will come through your products’ improved consistency, which will, in turn, enhance your brand reputation. The more and more quality, consistent products you put out, the more return customers and positive word of mouth you’ll gain. In the end, you’ll increase your production capacity at a lower operation cost while meeting market demand, which equals wins all around for the competitive space.

Why Choose Hefestus?

With decades of engineering expertise and a relentless focus on cannabis innovation, Hefestus stands apart in the world of pre-roll packaging automation. From small-batch craft brands to large-scale enterprises, our solutions are trusted worldwide and built to deliver.

Here’s why operators choose Hefestus:

- Engineering expertise in cannabis-specific packaging solutions: Our systems are designed from the ground up with cannabis in mind, not retrofitted from other industries.

- Innovative sealing and automation technologies: We’ve pioneered advancements that improve shelf life, ensure compliance, and streamline the packaging process.

- Customizable systems built for cannabis pre-roll operations: Every facility is different. Our modular systems adapt to your needs, whether you’re filling blunts, tubes, cartons, or dog walkers.

- Scalable solutions for both craft and enterprise brands: Start small or go big. Our equipment scales with your growth, helping you expand without overhauling your processes.

- Proven performance in global markets: With a footprint in international cannabis operations, Hefestus Systems has been tested, refined, and proven to deliver results in real-world environments.

Whether you’re looking to improve efficiency, meet compliance with ease, or scale without compromising quality, Hefestus has the equipment, tech, and team to get you there.

Scaling Pre-Roll Success with Smart Packaging Automation

All in all, pre-roll packaging machines are the future for cannabis operators seeking to scale across the highly competitive industry. When it comes to rising demand and labor costs, automated pre-roll packaging equipment, such as that made by Hefestus, is the solution for consistent, reliable, and efficient results.

Simply put, these machines help transform production bottlenecks into profit centers with higher efficiency, quality, and compliance controls. Ready to take your operation, whether current or new, to the next level? Explore Pre Roll Packaging Machines by Hefestus today! Get in touch with our team to begin customizing solutions for your business now.