The Expert Guide to Infused Pre-Rolls – 9 Things YOU Need to Know

How top operators protect margins, burn quality, and scalability…while everyone else overdoes it

Infused pre-rolls are no longer experimental. They’re a core revenue driver.

But once operators move past the beginner phase, a different reality sets in:

- Margins don’t scale the way spreadsheets say they should

- Burn issues quietly destroy repeat purchases

- Labor explodes as SKUs get more complex

- “Premium” becomes a liability instead of a differentiator

This expert guide is built from real conversations with infused pre-roll operators who’ve already made the mistakes and now help others avoid them.

1. The #1 Margin Killer: Over-Infusion

One of the most common expert-level realizations is simple:

More infusion ≠ more value.

At a certain point, often around the 20–30% infusion range, returns diminish fast. Adding more concentrate:

- Dramatically increases material cost

- Slows production

- Introduces burn and airflow issues

- Rarely increases consumer willingness to pay

There’s also a hard consumer ceiling most brands ignore:

“You can only get so high off a joint.”

Chasing extreme potency often turns into a vanity project…not a profit center.

Expert takeaway: If your infused SKU only works when you push infusion higher every quarter, the SKU is fundamentally unstable.

2. The Hidden Cost Nobody Budgets For: Material Loss

Most operators underestimate how much concentrate they’re losing during infusion.

In real-world production:

- Spraying

- Mixing

- Tossing

- Coating

…material sticks to hands, bowls, walls, tools, floors, everywhere except the joint.

Well-controlled operations might see ~5% loss.

Many manual or semi-manual workflows unknowingly lose 20% or more.

That’s not inefficiency…that’s margin evaporation.

Expert takeaway: Every added process step increases loss. Infusion has a half-life.

3. Burn Quality Is the Brand (And Infusion Is the Enemy of Burn)

Burn issues don’t usually come from flower quality.

They come from imbalance.

Common expert-level burn failures:

- Non-homogenized infusion pulling to one side

- Over-sprayed flower burning faster than oil

- Oil pooling near the tip or filter

- Sticky concentrate migrating during combustion

The result?

- Canoeing

- Harsh smoke

- Oil hitting lips

- Joints that won’t pull near the end

Heavily infused joints often look premium, but smoke terribly.

Expert takeaway: There’s a narrow “happy medium” where infusion enhances the experience instead of destroying it.

4. The Kief-Coated Trap: Looks Amazing, Sells Poorly at Scale

Kief-coated, multi-layered infused joints are everywhere on Instagram…but almost nowhere in high-volume production.

Why?

Because they require:

- Multiple manual stations

- High labor touchpoints

- Long cycle times

- Significant material loss

- Constant QC babysitting

They also appeal to a tiny slice of the market.

The majority of consumers don’t buy the most potent, most complex joint. They buy what burns well, tastes decent, and fits their budget.

These SKUs can make sense for:

- Brand credibility

- Limited drops

- Marketing moments

They almost never make sense as a volume SKU.

Expert takeaway: If your infused SKU only works as a social media flex, it’s not a scalable product.

5. The Smart Entry Point: Start Dry, Not Sticky

For operators adding infusion for the first time, the expert consensus is clear:

Start with drier, easier-to-homogenize material.

Why?

- It blends more evenly

- It introduces fewer burn issues

- It runs cleanly through automated systems

- It minimizes process complexity

Jumping straight into sticky extracts multiplies risk without adding early value.

Expert takeaway: Your first infused SKU should teach you control…not test your limits.

6. Scalability Is Decided Before the SKU Launches

One of the most painful patterns in infused pre-rolls:

- A brand launches a complex infused SKU

- It sells well

- Demand grows

- Production collapses

Why?

Because the SKU:

- Requires hand processes

- Can’t be automated cleanly

- Needs massive labor to scale

At that point, operators are trapped. Success becomes the bottleneck.

Expert takeaway: If you can’t automate it later, don’t romanticize it now.

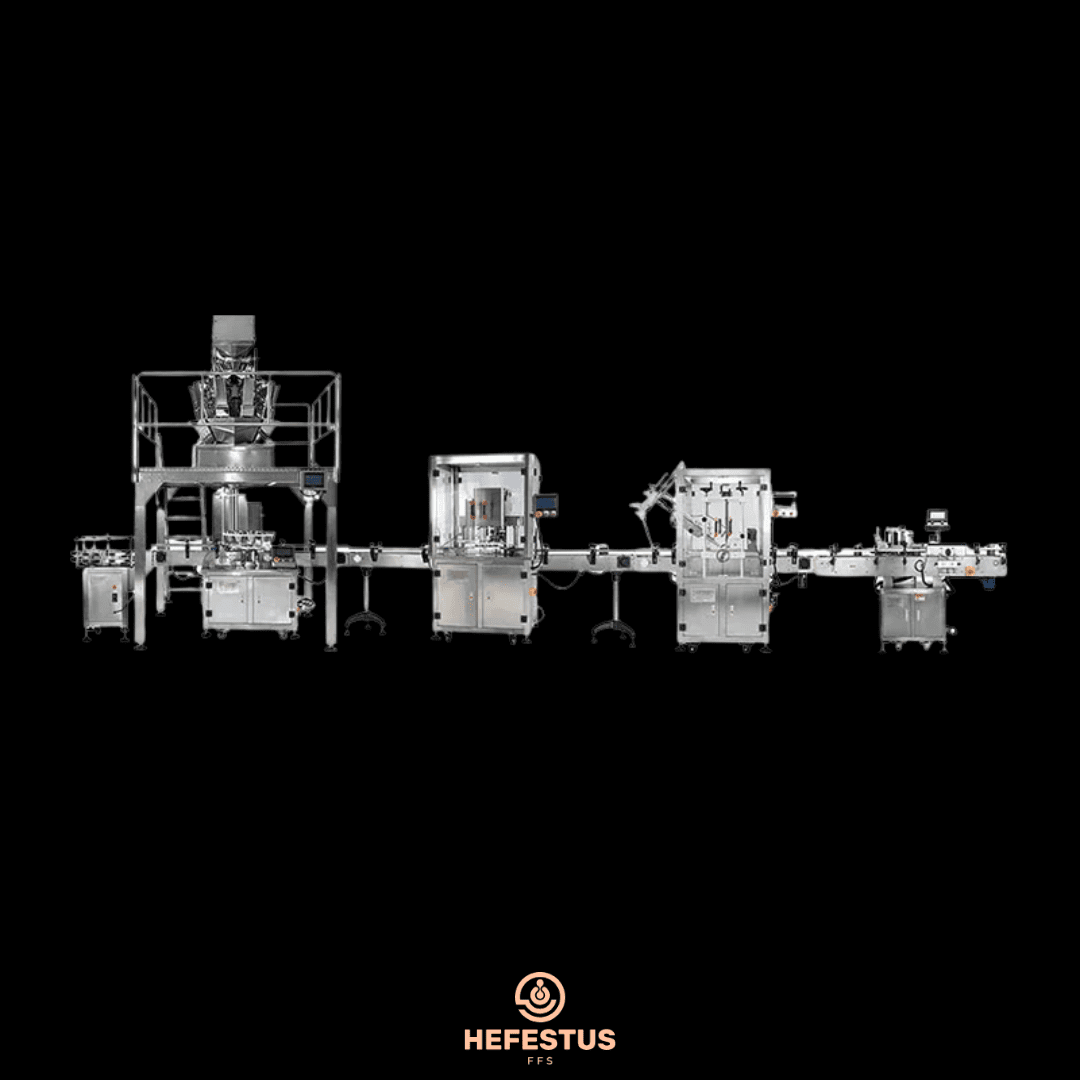

7. Automation Isn’t About Speed…It’s About Survival

Operators usually move from manual to automated infusion for one reason:

They can’t keep up with demand without losing control.

In real terms:

- Around 15–20k infused units per month, manual systems stop penciling

- Labor costs spike

- Consistency drifts

- ROI on automation suddenly makes sense — fast

Automation doesn’t just increase throughput. It stabilizes:

- Dosing

- Burn behavior

- Labor planning

- Margin predictability

Expert takeaway: Automation isn’t a growth luxury — it’s how you protect a product that’s already working.

8. The Real Expert Move: Compress R&D Time

One of the most overlooked advantages of working with experienced infusion teams isn’t equipment…it’s pattern recognition.

Operators often spend:

- Months in trial and error

- Burning material

- Reworking failed SKUs

Experienced teams can compress that to hours.

Real example:

- Inconsistent crumble sizes blocking scale

- Simple screening adjustment

- Minor machine tuning

- Perfect product running in ~15 minutes

That’s not magic…it’s experience.

Expert takeaway: The fastest path to a scalable infused SKU is borrowing experience, not inventing it.

9. Ego Is the Silent Killer of Good Infused Products

Many failed infused launches share one trait:

“I know what I’m doing.”

Master growers and brand founders often underestimate how different manufacturing is from cultivation.

Letting go of ego:

- Shortens timelines

- Reduces cost

- Improves outcomes

- Prevents dead-end SKUs

Expert takeaway: The smartest operators don’t prove they’re right…they prove they’re profitable.

Final Expert Takeaway

The best infused pre-rolls aren’t the most complex. They’re the most intentional.

They:

- Use infusion to enhance — not mask

- Balance potency, burn, and cost

- Align SKUs with real market demand

- Design for scale from day one

- Leverage expertise instead of reinventing it

Infused pre-rolls will continue to dominate the category, but only operators who simplify intelligently will win it.