Types of Filling Machines

Understanding the different types of filling machines is critical for any food manufacturer looking to improve efficiency, reduce waste, and scale production intelligently. The filling stage directly affects portion accuracy, product safety, production speed, and overall profitability. A poorly selected system can lock you into unnecessary overfill costs, sanitation challenges, and growth limitations.

In this guide, you’ll get a clear, practical breakdown of the main types of filling machines used in food automation—how they work, where they perform best, and how to choose the right one based on product behavior, production volume, and long-term operational goals.

What Is a Filling Machine?

Before comparing the different types of filling machines, it’s important to define the foundation: what is a filling machine?

A filling machine is a specialized piece of packaging equipment designed to dispense a precise amount of product—liquid, paste, powder, or solid—into containers. In food automation, this process must be accurate, hygienic, repeatable, and scalable.

In manual operations, workers pour or scoop product into containers. In automated systems, filling machines measure volume or weight using calibrated mechanisms and synchronize with conveyors, sealers, and labeling systems. In modern food packaging lines, filling equipment sits between product preparation (mixing, batching, cooking) and closing or sealing operations. It controls portion accuracy, production speed, waste levels, and ultimately profit margins.

A filling machine is not just a dosing device—it is the yield control center of the entire packaging line.

Why Filling Machine Selection Matters in Food Production

Choosing among the available types of filling machines is not a technical detail. It is a strategic decision that directly affects efficiency, food safety, and long-term scalability.

Product Consistency and Yield Control

In food manufacturing, small deviations multiply quickly. Overfilling by even a fraction of a gram across millions of units creates measurable raw material loss. Underfilling creates regulatory exposure and customer dissatisfaction.

The choice between volumetric, weight-based, or flow-based systems determines how well your line compensates for density variation, temperature fluctuation, and texture inconsistency. High-viscosity sauces behave differently from low-density beverages, and your filling technology must reflect that reality.

A properly matched filling machine protects both product integrity and profit.

Food Safety, Hygiene, and Compliance

Food production demands hygienic design. Modern filling machines must support:

- Clean-In-Place (CIP) capability

- Smooth, residue-resistant surfaces

- Reduced dead zones where bacteria can accumulate

- Compatibility with Modified Atmosphere Packaging (MAP) where required

In dairy, ready meals, and chilled products, sanitation design is as critical as dosing accuracy. Equipment geometry, sealing integration, and material selection influence contamination risk and cleaning time. A poorly designed filling system increases downtime and regulatory vulnerability.

Scalability and Automation Readiness

Food businesses rarely remain static. What begins as semi-automatic production often evolves into fully automated packaging lines.

A filling machine must integrate seamlessly with:

- Sealing systems

- Labeling machines

- Inspection units

- Robotic case packing

If the equipment cannot scale, expansion becomes expensive and disruptive. Selecting the right configuration from the beginning protects future growth.

Main Types of Filling Machines by Filling Technology

Understanding the core filling technologies is essential when evaluating types of liquid filling machine systems and other food filling solutions.

Volumetric Filling Machines

Volumetric systems dispense a predetermined volume during each cycle. They commonly use piston-cylinder assemblies or chamber-based dosing mechanisms.

These machines are particularly effective for medium to high-viscosity foods such as sauces, dressings, yogurt, dips, and chunky products like salsa. Because they physically draw and release a fixed volume, they handle particulate inclusions reliably.

However, volumetric systems require careful maintenance. Mechanical wear and cleaning complexity increase with production scale. For operations handling multiple SKUs, changeover planning becomes important to minimize downtime.

Volumetric filling remains one of the most versatile and widely adopted filling principles in food automation.

Weight-Based (Load Cell) Filling Machines

Weight-based systems use precision load cells to measure product mass in real time. The filling cycle stops automatically once the target weight is achieved.

This approach excels in applications where product density fluctuates due to temperature or formulation changes. It is particularly suitable for high-value products where overfill directly affects margins.

The trade-off is typically speed. Because each fill cycle depends on live weight feedback, throughput may be slightly lower than purely volumetric systems. However, for premium or regulatory-sensitive food products, the precision advantage often outweighs the speed difference.

Flow Meter Filling Machines

Flow meter fillers measure the exact amount of liquid passing through electronic sensors. Magnetic or mass flow meters provide continuous monitoring during the fill cycle.

This technology is ideal for edible oils, dairy beverages, juices, and other low- to medium-viscosity liquids. It supports high-speed production while maintaining excellent accuracy.

Flow-based systems also simplify cleaning procedures and enable fast changeovers between products. For manufacturers prioritizing efficiency and adaptability, this method offers a strong balance between speed and control.

Pump Filling Machines

Pump filling machines use positive displacement pumps or lobe pumps to move product into containers.

These systems are effective for thick, shear-sensitive, or aerated products such as creams, honey, heavy sauces, and certain dairy formulations. Because the pump controls product movement, they handle variable textures reliably.

At scale, pump-based systems demand careful calibration and maintenance. Their flexibility is a strength, but mechanical complexity increases operational responsibility.

Overflow (Level) Filling Machines

Overflow filling machines fill containers to a consistent visual level. Excess liquid returns to the supply tank once the predetermined height is reached.

This method works well for clear liquids where visual uniformity matters. However, it is not ideal for chunky or highly viscous foods. Overflow systems prioritize appearance over precise weight control, making them more suitable for certain beverage or cosmetic applications than dense food products.

Types of Filling Machines by Machine Configuration

Beyond filling principle, configuration determines speed, footprint, and operational rhythm.

Inline Filling Machines

Inline machines move containers in a straight path beneath filling heads. They are well suited to moderate production volumes and flexible SKU changes.

Maintenance access is generally easier due to their open design. They allow manufacturers to scale gradually without committing to large, high-speed installations. For small to medium food producers, inline systems provide operational control with manageable investment.

Rotary Filling Machines

Rotary systems use a circular carousel to move containers through continuous filling stations. This configuration supports high throughput and compact layouts.

Because motion is uninterrupted, rotary filling machines achieve significantly higher speeds than most inline systems. They are common in beverage, dairy, and high-volume packaged food environments where output consistency and floor space efficiency are priorities.

Manual vs Semi-Automatic vs Fully Automated Filling Machines

Automation level determines labor dependency and growth potential.

Manual filling machines are primarily used for laboratory testing, pilot production, or specialty small-batch operations. They are not scalable for commercial food production.

Semi-automatic systems provide partial automation while requiring operator involvement for container placement or initiation. They serve as transitional equipment for expanding businesses.

Fully automated filling systems integrate dosing, sealing, inspection, and discharge. These systems deliver consistent output, reduce labor variability, and support large-scale food automation. In competitive markets, full automation increasingly defines operational advantage.

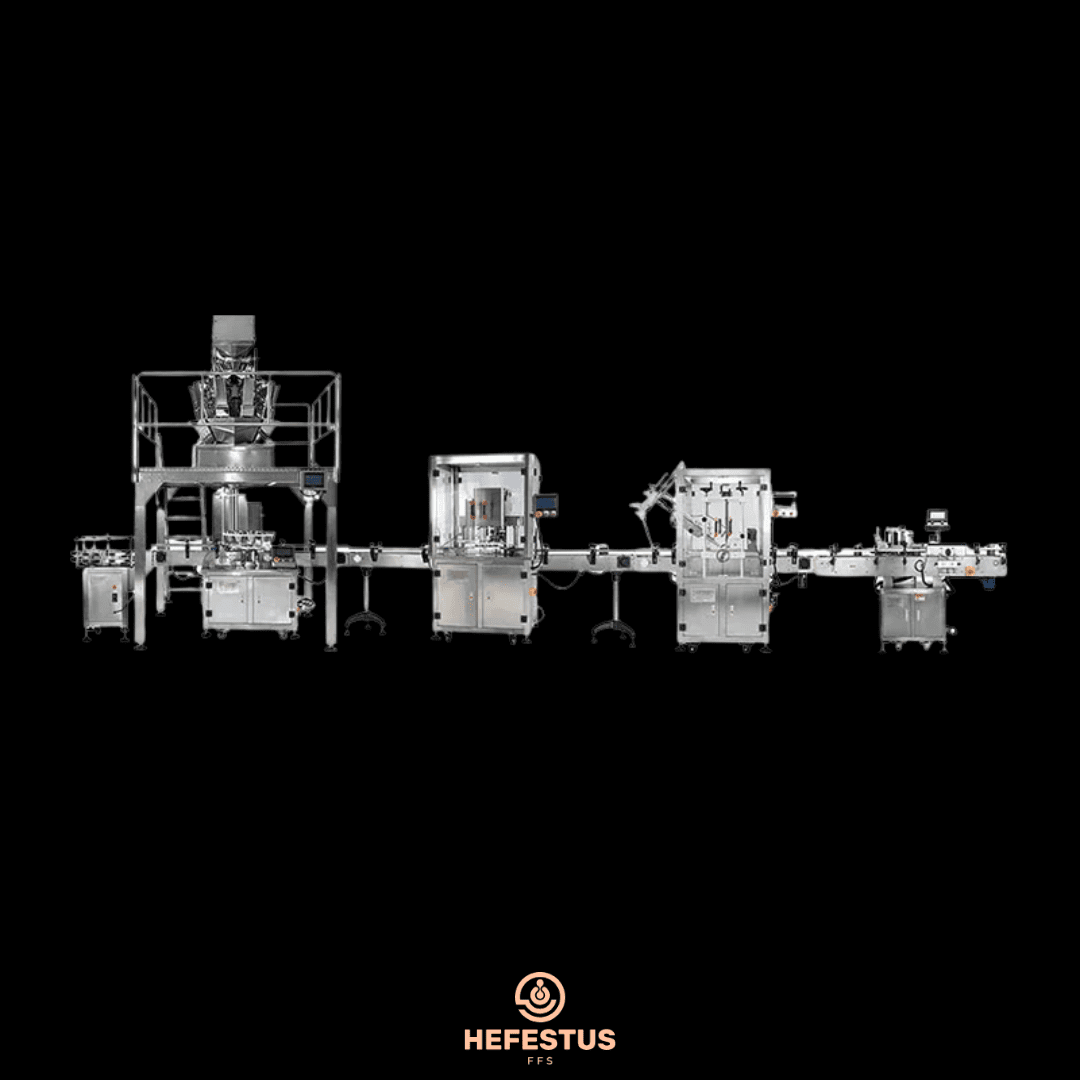

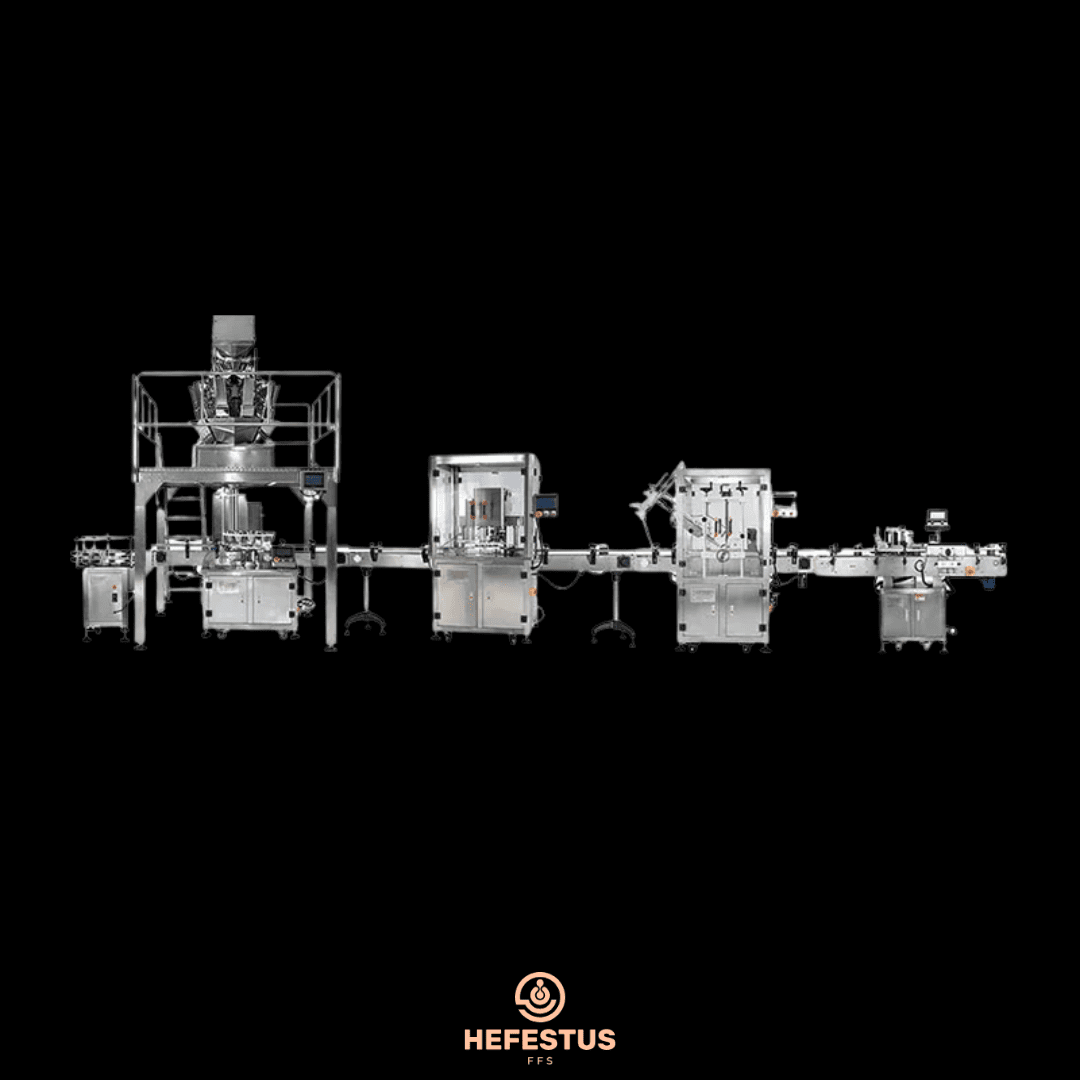

Filling Machines in Integrated Food Packaging Systems

The most advanced food producers do not treat filling as a standalone function. They integrate it within complete packaging architectures.

Fill & Seal Systems

Fill-and-seal platforms combine dosing and container closure within one coordinated system. This reduces exposure time between filling and sealing, lowering contamination risk and improving hygiene.

These systems are common in ready meals, dairy cups, and sauce packaging where controlled environments are essential.

Form Fill Seal (FFS) Machines

Form Fill Seal technology forms packaging material, fills it with product, and seals it in one continuous automated process.

FFS systems reduce manual handling, improve sanitation, and increase production speed. They represent a benchmark in modern food automation, particularly in high-volume packaged goods.

How to Choose the Right Filling Machine for Your Food Product

A structured decision process prevents costly mistakes.

First, evaluate product behavior. Consider viscosity, particulate size, temperature sensitivity, and foam characteristics. These physical properties directly determine which filling principle performs best.

Next, assess production volume. Plan not only for current output but for projected growth within 12 to 24 months. Underestimating demand often forces premature equipment upgrades.

Then, analyze packaging format. Cups, trays, pouches, bottles, and rigid containers each impose different mechanical requirements.

Finally, define automation goals. If reducing labor and integrating robotics are priorities, select equipment that aligns with long-term automation strategy rather than short-term convenience.

Final Thoughts: Filling Machines Are a Strategic Decision

Filling machines determine yield efficiency, food safety reliability, operational speed, and scalability. The wrong selection creates persistent inefficiencies. The right one becomes the foundation for sustainable growth.

In food automation, filling is not a component—it is a control point that shapes your production ceiling.

If this guide helped clarify your decision process, share it with your operations team or explore deeper automation resources to refine your packaging strategy.