Types of Meat Packaging

Choosing the right meat packaging method isn’t just a technical detail. It’s a strategic decision that determines shelf life, food safety, product appearance, and ultimately, profitability. The meat industry has become increasingly competitive, and processors are under pressure to deliver fresher products, reduce waste, and streamline production despite labor shortages and rising operational costs.

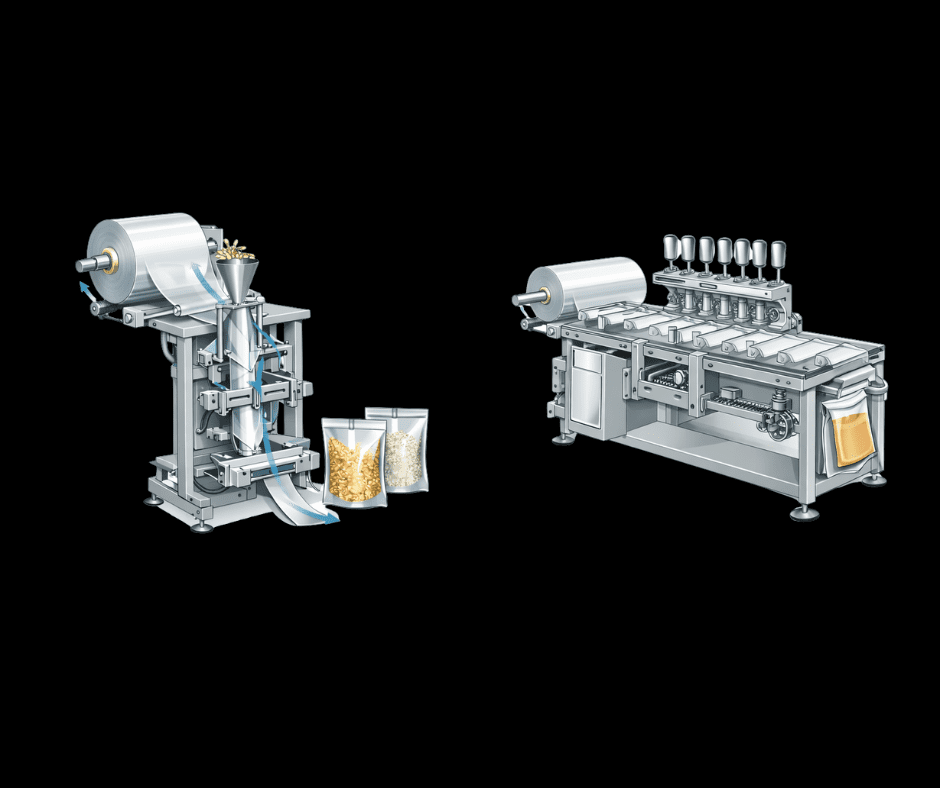

This is exactly why packaging has evolved beyond simple wrapping. Today, the most successful processors rely on advanced technologies and automated machinery to maintain consistency, protect product quality, and meet strict retail demands. Hefestus, a global innovator in food automation, has seen firsthand how packaging choices reshape efficiency and competitiveness.

Below is a clear breakdown of the main types of meat packaging, what they’re good for, and how automation strengthens each method.

Why Packaging Matters More Than Ever

Before diving into specific methods, it’s worth addressing the reality shaping the industry today. Consumers expect fresh-looking meat with long shelf life. Retailers demand packaging that is durable, clean, leak-proof, and visually appealing. Regulators require packaging that ensures safety and minimizes contamination risks. And processors need solutions that reduce dependence on unstable labor.

Packaging sits directly in the middle of all these pressures. The right method doesn’t just preserve meat — it reduces production bottlenecks, improves product consistency, and opens new opportunities for branding and distribution.

1. Vacuum Packaging (VP)

What it is:

Vacuum packaging removes air from the package before sealing, significantly reducing oxygen exposure. This slows oxidation and bacterial growth, extending shelf life while keeping flavors intact.

Where it’s used:

Beef, poultry, pork, processed meats, and primal cuts.

Advantages:

- Strong shelf-life extension

- Reduced freezer burn

- Cost-effective

- Excellent for bulk and B2B applications

Disadvantages:

- Meat can look darker or less appealing due to oxygen removal

- Product deformation is possible with soft cuts

Automation angle:

Modern vacuum sealing machines deliver consistent vacuum levels, tight seals, and leak prevention that manual processes simply can’t guarantee. High-output lines depend on automated vacuum systems to maintain speed, repeatability, and hygiene.

2. Modified Atmosphere Packaging (MAP)

What it is:

MAP replaces the air inside a package with a controlled gas mix — commonly oxygen, carbon dioxide, and nitrogen. By adjusting this mixture, processors can preserve color, freshness, and flavor while extending shelf life.

For a deeper breakdown of how MAP works, the types of gas mixtures used, and the science behind shelf-life improvement, you can read our full guide on what Is MAP packaging for meat.

Where it’s used:

Retail-ready meat, fresh cuts, poultry, premium products.

Advantages:

- Ideal color preservation (e.g., bright red beef)

- Increased shelf life compared to simple wrapping

- Enhanced product presentation

- Reduced waste for retailers and processors

Disadvantages:

- Requires specialized machinery

- Higher packaging material costs

Automation angle:

MAP is extremely sensitive to consistency. A slight misbalance in gas levels can compromise freshness or color. Automated MAP systems — including those designed by Hefestus — ensure precise gas dosing, sealing accuracy, and leak-proof performance. For processors scaling production, automation is the only sustainable path.

3. Skin Packaging (SP)

What it is:

Skin packaging uses a transparent film that drapes tightly over the meat, conforming to its shape and sealing onto a tray or board. It’s visually striking and eliminates product movement.

Where it’s used:

Steaks, poultry fillets, smoked products, high-value cuts.

Advantages:

- Premium appearance

- Reduced juices spreading inside the package

- Strong protection against physical damage

- Better shelf life than simple wrapping

Disadvantages:

- Not ideal for products requiring oxygen exposure

- Cycle times can be slower on outdated machines

Automation angle:

Modern skin packaging lines require fine control of film tension and sealing temperature. Automated systems ensure the film adheres smoothly, creating a strong vacuum-tight finish without damaging the product.

4. Vacuum Skin Packaging (VSP)

What it is:

VSP is a hybrid of vacuum and skin packaging. The air is removed like in vacuum packaging, but the finish resembles skin pack. This creates a premium, oxygen-free display that enhances shelf life.

Where it’s used:

Marinated meats, premium steaks, ready-to-cook products.

Advantages:

- Long shelf life

- High-end visual appeal

- Strong tamper resistance

- Perfect for branding and retail displays

This method is growing rapidly in retail because it boosts perceived value — meaning processors can command better margins.

5. High-Barrier Packaging

What it is:

High-barrier films are engineered to block oxygen, moisture, and other external factors. They’re often used in conjunction with MAP or vacuum applications.

Where it’s used:

Long-distance distribution, export products, frozen meat.

Advantages:

- Maximum protection

- Excellent for long shelf life

- Strong durability during transport

Barrier films can only perform well when equipment can reliably seal them — another area where automation matters.

6. Bulk Meat Packaging

What it is:

Large foodservice or industrial packs using heavy-duty vacuum bags, liners, and crates.

Where it’s used:

Meat processing plants, wholesalers, distribution centers.

Advantages:

- Cost-efficient

- Simplifies large-volume handling

Although not as glamorous as retail packaging, it’s a critical part of the supply chain. Automated bulk systems prevent leaks and contamination during high-volume processing.

How These Methods Compare (Practical Summary)

| Packaging Type | Shelf Life | Appearance | Cost | Best For |

| Vacuum | High | Darker | Low | Bulk, primal cuts |

| MAP | High | Excellent | Medium-High | Retail-ready meat |

| Skin | Medium-High | Premium | Medium-High | High-value cuts |

| VSP | Very High | Premium | High | Premium + marinated meats |

| High-Barrier | Very High | Varies | High | Long distribution chains |

| Bulk | Medium | Low | Very Low | Industrial use |

This table helps processors choose the best method based on distribution, consumer expectations, and cost targets.

Automation: The Backbone of Modern Meat Packaging

The biggest shift in the industry isn’t the type of packaging — it’s the machinery behind it. Manual packaging is slow, inconsistent, labor-intensive, and prone to contamination risks. Automation solves these problems, providing:

- Constant sealing quality

- Accurate gas flushing for MAP

- High-speed throughput

- Reduced labor dependency

- Lower overall production cost

- Improved hygiene and safety

- Seamless integration into existing lines

This is why leading processors are investing in automated tray sealers, MAP systems, skin packaging machines, and complete end-of-line solutions.

Hefestus has been at the center of this shift, designing advanced, compact, and highly efficient packaging systems tailored for meat processors of all sizes. From next-generation MAP technology to high-output sealing units, automation is becoming the competitive foundation of forward-thinking meat producers.

For processors handling high-volume ground meat products, our commercial ground meat packaging machine delivers the output, sealing consistency, and automation reliability needed to eliminate manual bottlenecks and dramatically improve line efficiency.

Choosing the Right Packaging Method for Your Operation

Any processor selecting a packaging method should consider:

- What type of meat is being packed?

- What shelf life is required by your customers?

- How important is visual appearance for retail?

- What is the distribution distance?

- Are marinated or fragile products involved?

- What’s the expected throughput?

- Is your current labor force stable or unreliable?

- How ready is your facility for automation?

The answer isn’t universal. It’s operational. And the wrong choice can quietly erode margins or create bottlenecks.

Final Thoughts

The meat packaging landscape has evolved into a mix of science, engineering, and consumer psychology. The right packaging type doesn’t just protect meat — it strengthens your entire production chain.

Automation is now the standard for processors who want consistent quality, longer shelf life, and scalable, reliable throughput. As the industry continues to push toward efficiency and precision, technologies developed by companies like Hefestus are defining the next generation of meat packaging.

If you’re evaluating your packaging strategy or exploring automation upgrades, now is the time to rethink your approach and future-proof your operation.