What Is a Filling Machine?

A filling machine is not just equipment that “puts product into a container.” In modern production, it is the control point that determines dosing accuracy, throughput, hygiene, and ultimately profitability.

Whether you operate in food, pharmaceuticals, cosmetics, or chemicals, the right filling system governs consistency, protects product integrity, and integrates with sealing, labeling, and inspection. Understanding what a filling machine actually does—beyond the textbook definition—can prevent costly bottlenecks and margin erosion.

In this guide, you’ll learn what is a filling machine, how the filling machine process works, the technologies that matter, common failure points, and how integrated automation is reshaping production lines.

What a Filling Machine Actually Does in a Food Automation Line

In automated food production, a filling machine controls far more than volume.

Controls Dose Accuracy

Precision dosing reduces product giveaway. Even a 1% overfill on high-volume SKUs can translate into six-figure annual losses.

Controls Speed Consistency

A well-calibrated filler maintains cycle timing across shifts, preventing downstream congestion at sealing or labeling stations.

Protects Product Integrity

Modern systems minimize air inclusion, manage foaming, and support hygienic design—critical in regulated industries.

Interfaces with Sealing & Conveying

A filling machine must synchronize with capping, Modified Atmosphere Packaging (MAP), inspection systems, and conveyors to prevent misalignment and downtime.

This systems-level integration is where modern automation separates itself from basic filler equipment.

The Filling Machine Process (Step-by-Step, Real World)

The filling machine process varies by application but typically follows these operational phases:

- Product Infeed & Conditioning

Product moves from a storage tank or hopper. It may require agitation, temperature control, or filtration before dosing. - Container Presentation

Bottles, cups, trays, or pouches are indexed into position using conveyors or rotary systems. - Filling Execution

The machine dispenses product via volumetric, gravimetric, pressure, or pump-based methods. - Verification (If Applicable)

Net weight fillers use load cells to confirm accuracy. Vision systems may inspect fill level. - Transfer to Sealing Stage

Containers proceed to capping, heat sealing, or vacuum sealing without manual intervention.

The efficiency of this sequence determines total line performance—not just fill accuracy.

Common Filling Technologies (Only What Matters)

Here are the core technologies used in modern production:

Volumetric Filling (Piston / Pump)

Ideal for viscous products like sauces, creams, or gels. Delivers consistent volume regardless of container shape.

Time-Pressure / Gravity Filling

Used for thin, free-flowing liquids such as water or juice. Cost-effective but sensitive to viscosity changes.

Net Weight Filling

Best for high-value or bulk products. Uses load cells to ensure exact weight, minimizing giveaway.

Rotary Filling

Designed for high-speed lines. Suitable for beverage, dairy, and large-scale food production where throughput is critical.

Each method serves a specific operational context. Selecting incorrectly can limit scalability.

Why Filling Machines Fail in Food Production

Failures in food filling operations are rarely caused by the filling machine alone. In most cases, breakdowns in performance stem from systemic issues across the production line.

Product Variability

Changes in viscosity, temperature, or particulate content directly affect dosing accuracy. A system calibrated for one consistency may struggle when raw material properties shift, leading to underfills, overfills, or inconsistent product presentation.

Poor Line Integration

A high-speed filler feeding into a slower sealing or labeling station creates recurring stoppages. When equipment speeds are mismatched, the result is constant buffering, micro-stoppages, and reduced overall equipment effectiveness (OEE).

Inconsistent Container Positioning

Even minor misalignments can disrupt fill precision. Containers that are not properly indexed or stabilized increase the risk of spills, inaccurate dosing, and rejected units.

Overengineering the Filler

Upgrading to a more advanced filling machine without addressing upstream feeding or downstream sealing often relocates the bottleneck rather than eliminating it. True performance gains require system-level optimization.

Sustainable automation is achieved when filling is designed as part of a unified production architecture—not as an isolated upgrade.

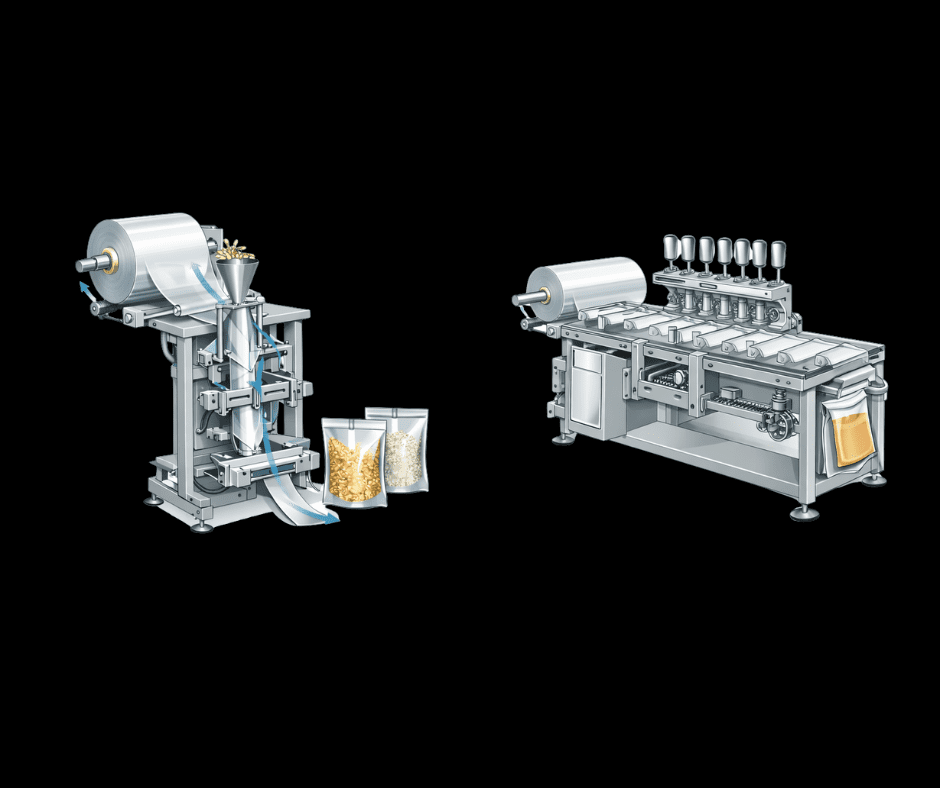

Standalone Filling vs Integrated Fill & Seal Systems

The way a filling machine is structured within a production line directly affects speed, hygiene, and reliability. The key difference lies in whether the filler operates alone or as part of an integrated system.

Standalone Fillers

Standalone filling machines operate as independent units within a packaging line.

- Operate as independent units

They rely on separate conveyors and downstream machines to complete the process. - Increase handoffs

Product moves between multiple machines, adding transition points where delays or misalignment can occur. - Introduce synchronization risk

When upstream and downstream equipment run at different speeds, minor timing mismatches can disrupt flow. - Often become bottlenecks

If the filler cannot keep pace with sealing or inspection stages, overall line throughput suffers.

Standalone systems are common in modular or smaller operations but can limit scalability.

Integrated Fill & Seal Systems

Integrated systems combine filling and sealing into a synchronized process.

- Control throughput across stages

Filling and sealing operate under a unified control system, keeping output consistent. - Reduce contamination risk

Fewer transfer points mean less product exposure and better hygiene control. - Minimize downtime

With fewer mechanical transitions, there are fewer opportunities for jams or misfeeds. - Improve footprint efficiency

Combining stages reduces floor space and simplifies line layout.

Integrated automation simplifies operations and supports stable, scalable production.

How to Know If You Need a Filling Machine (or a Different System)

Upgrading to a filling machine — or moving to a more integrated system — usually becomes necessary when production friction starts limiting performance. The signals are operational, not theoretical.

You may need an upgrade if you experience:

- Manual filling labor dependency

If your team is heavily involved in measuring, positioning, or correcting fills, you’re relying on human consistency instead of process control. - Throughput ceilings limiting growth

When demand increases but output cannot scale without adding shifts or labor, the limitation is typically equipment-related. - Inconsistent product weights

Variations in fill volume lead to product giveaway, compliance issues, or customer complaints — all signs of insufficient dosing control. - High contamination or spoilage risk

Excessive handling or open transfers between stages increase exposure and reduce product stability. - Frequent changeover delays

Long adjustment times between SKUs signal that the system was not designed for flexibility.

If scalability, consistency, and operational stability are strategic priorities, an automation-first approach becomes less optional — and more foundational.

Filling Machines in Modern Food Automation

Today’s filling machines are no longer standalone dosing tools — they are engineered components within fully automated food production systems. Performance is measured not only by accuracy, but by how well the machine integrates, adapts, and scales.

Modern systems prioritize:

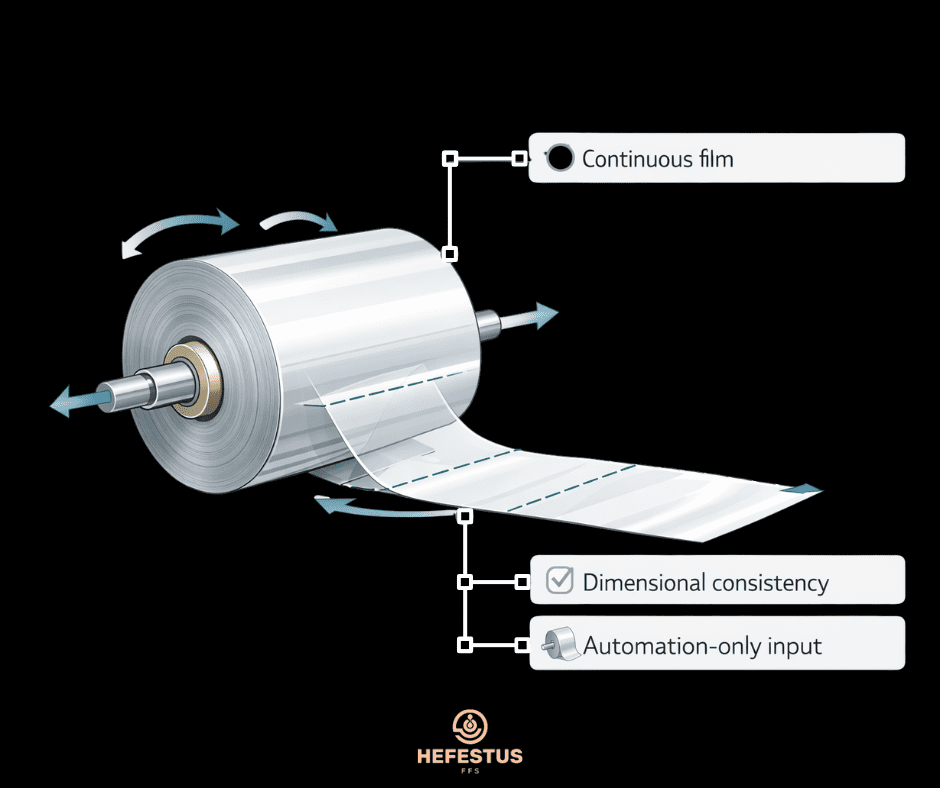

- Automation-first architecture

Filling equipment is designed to operate within synchronized production lines, reducing manual intervention and maintaining stable cycle timing. - Compatibility with MAP and hygienic design

Systems must support Modified Atmosphere Packaging and meet strict hygiene standards to preserve product quality and shelf life. - Rapid changeovers

As product variations increase, the ability to switch SKUs quickly without extended downtime becomes critical. - Compact footprints

Efficient line design reduces floor space while maintaining output, especially important in high-cost production environments. - Scalability without complete line redesign

Advanced systems allow capacity increases or product additions without replacing the entire production setup.

As food safety regulations tighten and consumer expectations rise, filling technology continues to evolve toward smarter sensors, servo-driven precision, and real-time performance monitoring — making adaptability as important as accuracy.

Conclusion

So, what is a filling machine?

It’s the operational core of automated production—controlling accuracy, speed, hygiene, and scalability. When engineered as part of an integrated system, it becomes a throughput controller rather than a standalone dispenser.

Understanding the filling machine process allows manufacturers to optimize efficiency, protect margins, and future-proof production lines.

If this guide clarified your approach, consider sharing it with your operations team or exploring advanced automation resources to deepen your strategy.