What Is MAP Packaging for Meat? Benefits, Process, and Shelf-Life Impact

In the modern meat industry, preserving freshness, extending shelf life, and maintaining product quality are critical concerns for both producers and retailers. One of the most effective solutions to address these challenges is MAP packaging for meat, also known as Modified Atmosphere Packaging.

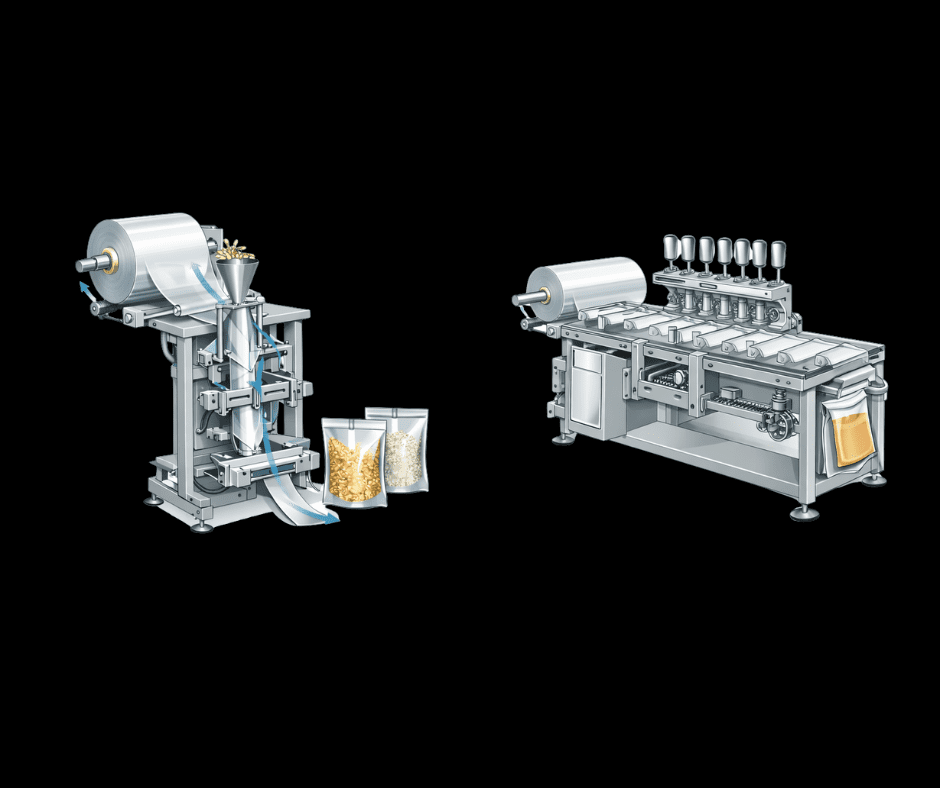

By pairing this technology with a reliable ground meat packaging machine, producers can ensure that meat products are efficiently portioned, safely sealed, and delivered to consumers at peak freshness. This combination of advanced packaging techniques and specialized equipment has revolutionized how ground meat is processed, stored, and sold.

Understanding MAP Packaging for Meat

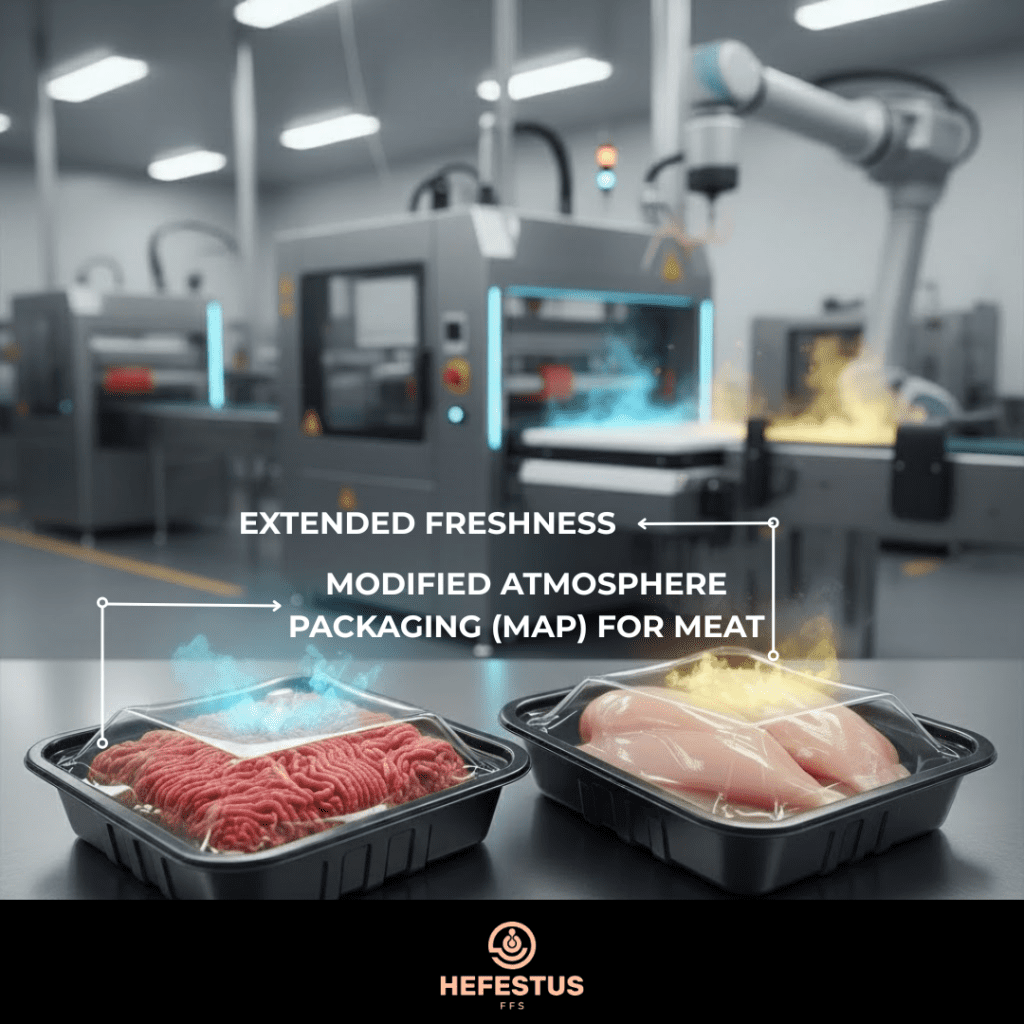

MAP packaging for meat involves replacing the air inside a package with a controlled mixture of gases, typically carbon dioxide, nitrogen, and oxygen, to slow down spoilage and preserve the product’s natural color, texture, and flavor. Unlike traditional vacuum packaging, which removes all air, MAP allows meat to retain its natural appearance while significantly extending shelf life.

The choice of gases and their proportions depends on the type of meat being packaged. For example, red meats like beef and lamb often require higher oxygen levels to maintain their bright red color, while poultry and processed meats benefit from higher carbon dioxide concentrations to inhibit microbial growth. By carefully controlling the internal atmosphere, MAP packaging ensures meat stays safe and appealing for longer periods.

Benefits of MAP Packaging for Meat

The benefits of MAP packaging for meat extend far beyond basic preservation, offering advantages for producers, retailers, and consumers alike.

Extended Shelf Life

One of the most significant advantages of MAP is the extended shelf life it provides. By slowing down microbial growth and oxidation, MAP allows meat to stay fresh days or even weeks longer than traditional packaging methods. This extension of shelf life not only reduces food waste but also increases flexibility in distribution, inventory management, and retail stocking.

Improved Product Appearance

Consumers are naturally drawn to meat that looks fresh, with a vibrant red or pink color and appealing texture. MAP packaging helps maintain this visual quality by preventing discoloration and degradation. Consistently attractive meat enhances consumer trust, encourages repeat purchases, and can even justify premium pricing.

Reduced Need for Chemical Preservatives

MAP can minimize or eliminate the need for chemical preservatives, making meat products more appealing to health-conscious buyers. This is particularly important for consumers who prioritize clean-label and natural foods. Maintaining freshness without added chemicals aligns with current market trends favoring minimally processed, wholesome products.

Enhanced Safety and Quality

By controlling the internal atmosphere of the package, MAP packaging reduces the risk of bacterial growth and spoilage. This contributes to safer meat products and helps processors meet strict food safety standards. The result is high-quality meat that remains consistent from production to consumption.

The MAP Packaging Process

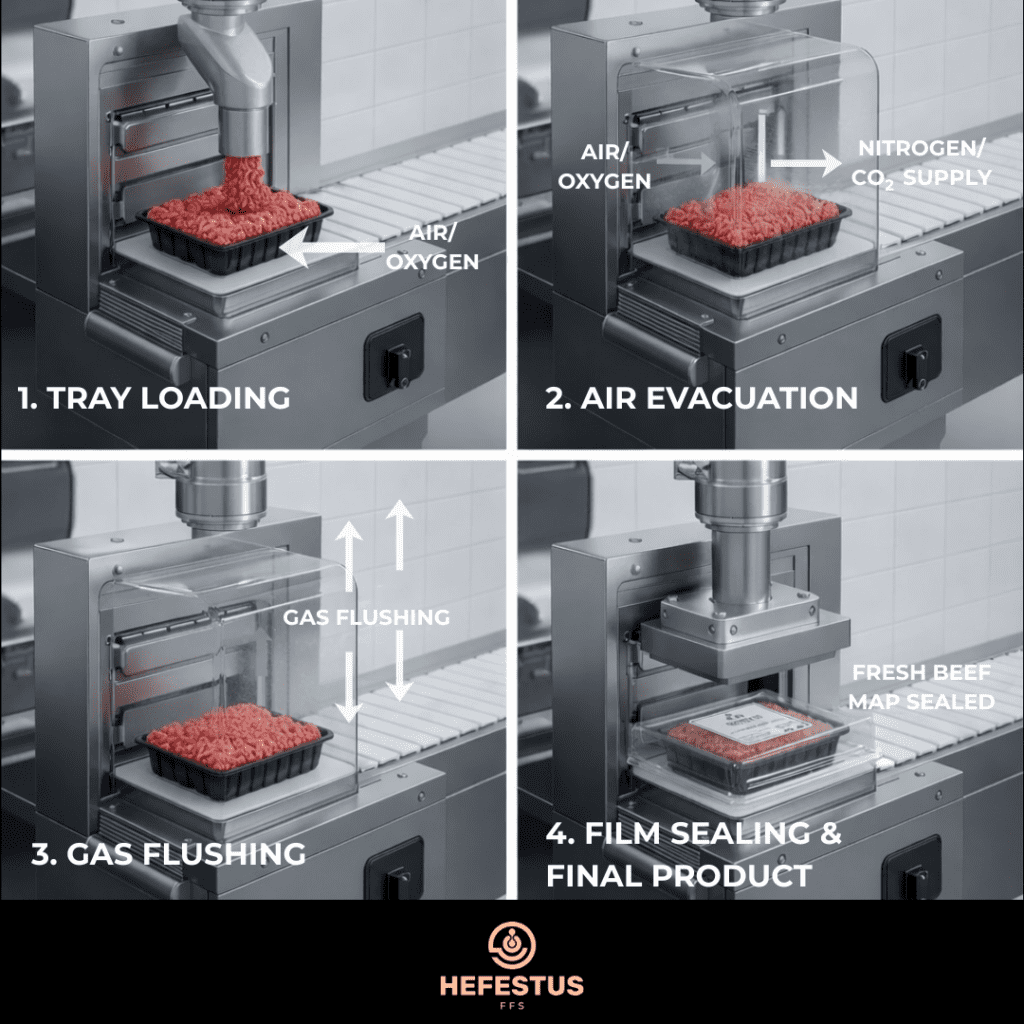

The process of MAP packaging for meat involves several key steps, each designed to maintain product quality, extend shelf life, and ensure consumer safety.

Product Preparation and Material Selection

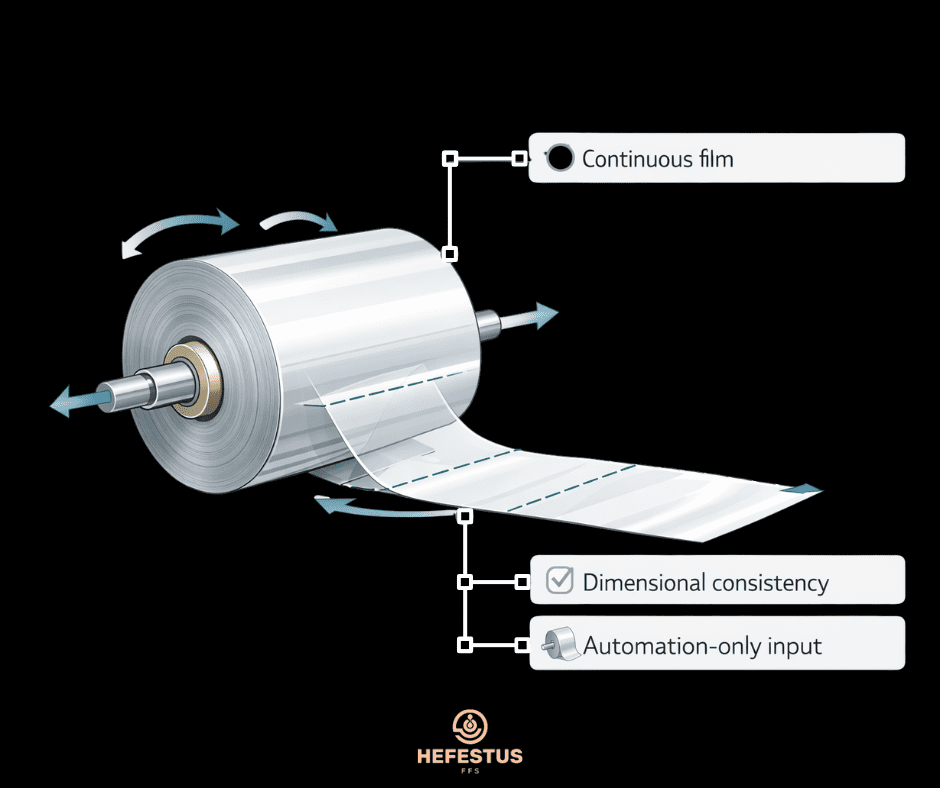

The process begins with preparing the meat and choosing the appropriate packaging material. Meat is typically placed in trays, pouches, or other containers designed to withstand the specific gas mixture. The packaging material must be impermeable to gases to maintain the modified atmosphere throughout the product’s shelf life, ensuring freshness and safety.

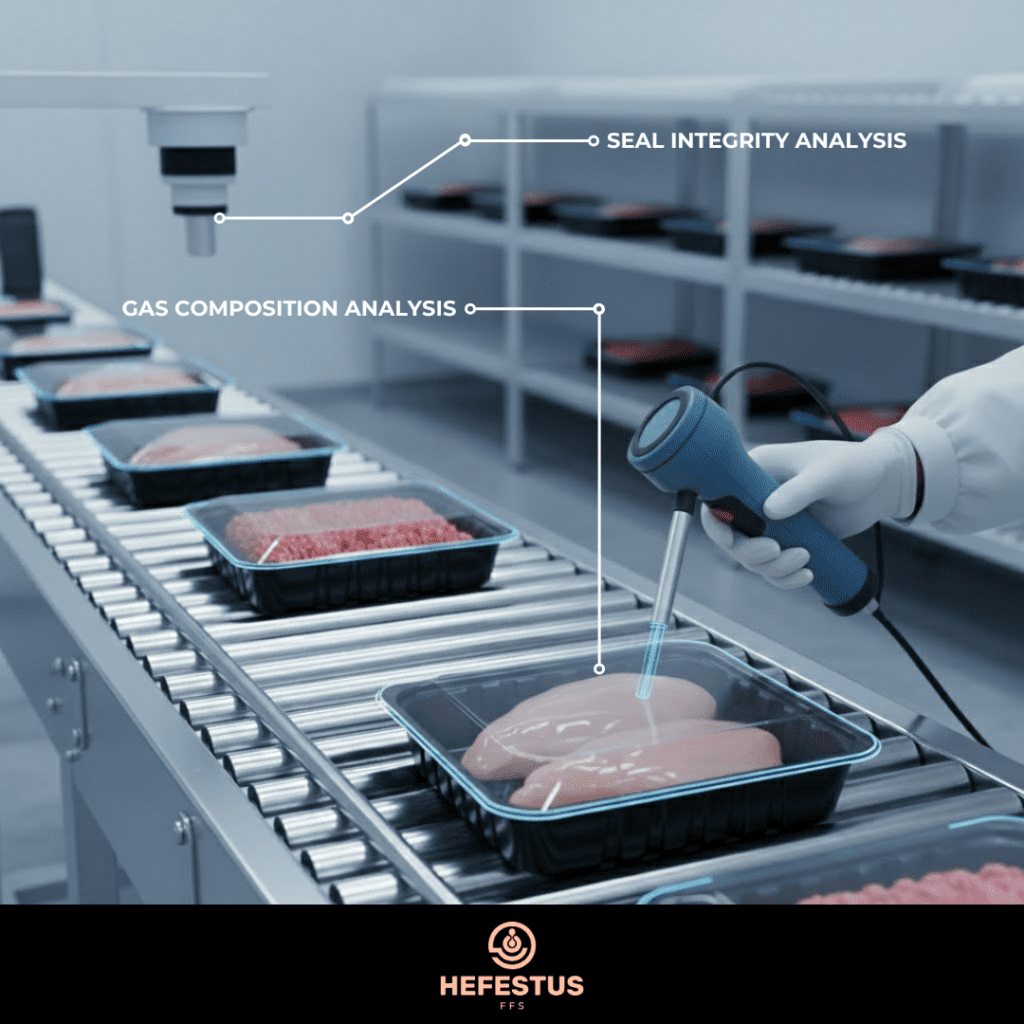

Gas Replacement and Package Filling

Once the meat is positioned, the air inside the package is evacuated or displaced, and the selected gas mixture is introduced. Advanced MAP packaging for meat systems carefully monitors the gas composition, filling the package with precise ratios to optimize freshness, color, and appearance. Proper gas replacement is critical to preserving both quality and safety.

Sealing and Labeling

After the package is filled with the correct gas mixture, it is securely sealed to prevent leakage and contamination. The sealed package is then labeled with essential product information, such as type, weight, production date, and best-before date, before being sent for refrigeration or freezing, depending on the product type.

Automation and Efficiency

Modern MAP packaging equipment often integrates automated gas flushing, sealing, and inspection systems. These advanced systems ensure consistent packaging quality, reduce human error, and improve efficiency at scale. This makes MAP packaging suitable for both small meat processing facilities and large commercial operations looking to optimize production and maintain high standards.

Shelf-Life Impact

One of the most important considerations for any meat processor or retailer is shelf life. MAP packaging for meat significantly extends the time meat can remain safe and appealing for consumption. For fresh beef, pork, and lamb, shelf life can increase from just a few days in traditional packaging to two to three weeks with MAP. Poultry and ground meats also see notable improvements, with some products lasting up to two weeks longer than standard packaging allows.

The extended shelf life provided by MAP has a direct impact on supply chain efficiency. Retailers can stock larger quantities without fear of spoilage, distributors can transport products over longer distances, and producers can better plan production schedules. In addition, reduced spoilage means lower food waste, which has both economic and environmental benefits.

Considerations and Best Practices

While MAP packaging for meat offers numerous advantages, following best practices is essential to maximize effectiveness and maintain product quality. Selecting the correct gas mixture for each type of meat is critical, as different meats require specific ratios to preserve color, texture, and freshness. Incorrect gas mixtures can lead to premature spoilage or undesirable changes in appearance and flavor.

Proper sealing and consistent refrigeration are also vital. Some key points to keep in mind include:

- Ensure seals are airtight and free from defects.

- Store packaged meat at recommended temperatures to prevent microbial growth.

- Minimize handling after packaging to avoid punctures or leaks.

Packaging materials must be carefully chosen to match the intended shelf life and storage conditions. Barrier films that prevent gas exchange are essential for preserving the modified atmosphere over time. Using substandard materials can compromise freshness and shelf life.

For processors looking to scale production, investing in automated MAP equipment can ensure consistent quality while reducing labor costs.

Conclusion

MAP packaging for meat has become a cornerstone of modern meat preservation. By controlling the internal atmosphere of a package, this technology extends shelf life, enhances product appearance, and reduces the need for chemical preservatives. From fresh beef and poultry to processed meats, MAP packaging for meat provides both economic and quality advantages for producers, retailers, and consumers alike.

As consumer demand for fresh, visually appealing, and clean-label meat products continues to grow, implementing MAP packaging is an effective way to stay competitive and meet market expectations. For meat processors looking to optimize their packaging lines, investing in a reliable MAP system is a strategic step toward efficiency, quality, and consumer satisfaction.