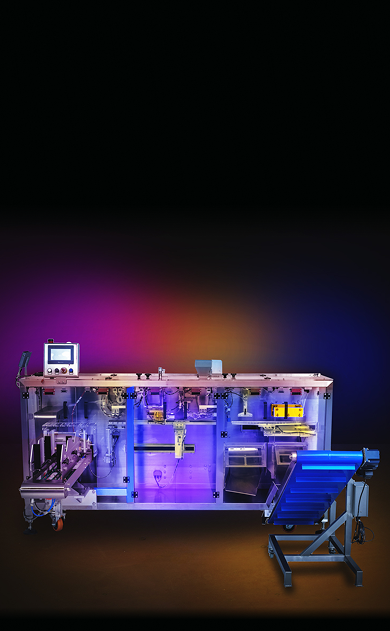

AutoBag Automated Cannabis Bag Filling Machine

Smarter, Faster, Fresher—Automated Cannabis Bagging at Scale

Freshness Locked In, Quality Sealed Tight

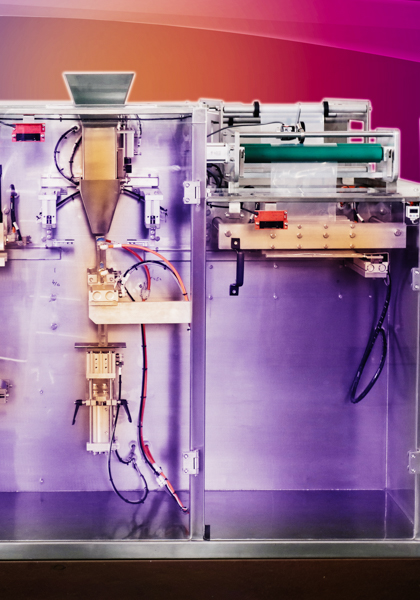

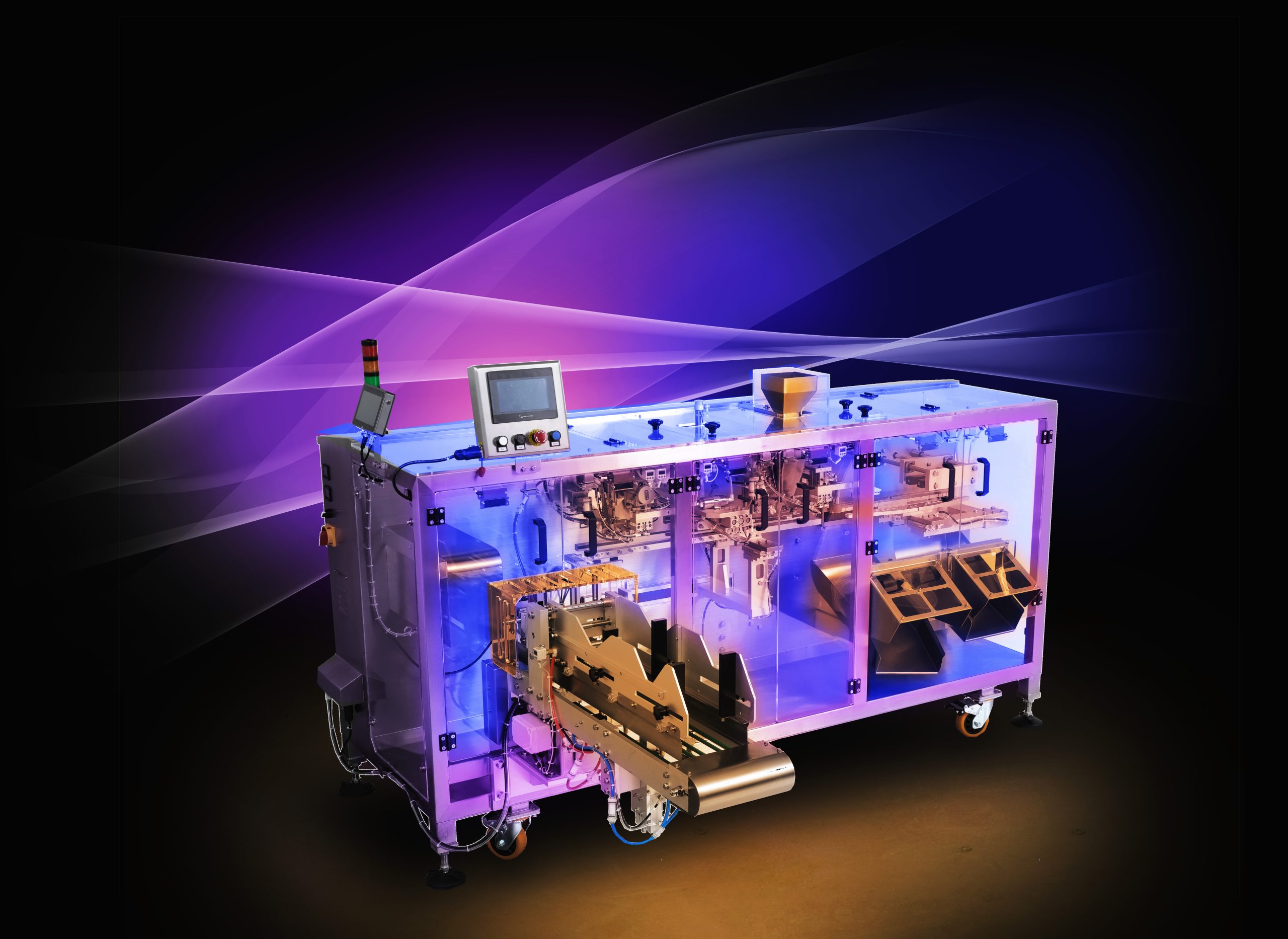

The AutoBag is a high-speed automated cannabis packaging machine system for efficient cannabis flower packaging in bags.

With optional Modified Atmosphere Packaging (MAP) technology to control oxygen levels AutoBag seals freshness and potency from packaging to purchase. Its straight-flow design ensures easy, safe monitoring and control.

From Bulk to Bag—The Automated Cannabis Packaging Machine You Can Trust

The AutoBag cannabis packaging machine ensures airtight sealing, extended freshness, and high-speed automation.

From Bulk to Bag—The Automated Cannabis Packaging Machine You Can Trust

The AutoBag cannabis packaging machine ensures airtight sealing, extended freshness, and high-speed automation.

Extended Shelf Life

AutoBag’s MAP technology preserves cannabis aroma and potency, helping reduce spoilage and enhancing consumer satisfaction.

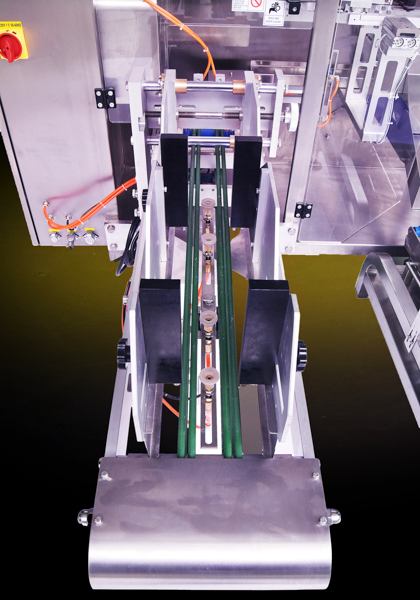

High-Speed Efficiency

Capable of reaching up to 26 bags per minute, the AutoBag flower packing device supports high production rates, helping producers meet demand without sacrificing quality.

Low Operational Costs

With a streamlined design and easy-clean components, AutoBag keeps operating and maintenance costs low, supporting high-volume production efficiently.

Enhanced Operator Safety

A comprehensive safety system prevents operators from accessing moving parts during operation, ensuring a secure work environment.

Versatile Bag Options

The AutoBag automated cannabis packaging machine accommodates a wide range of bag sizes, offering producers versatility across different product lines.

Minimal Product Waste

The “No Bag, No Dump” function prevents product waste by ensuring the machine only fills bags that are correctly positioned, improving efficiency and minimizing loss.

Additional Packaging Options

Hefestus also offers the AutoJar, a high-speed cannabis flower packaging system designed specifically for cannabis in bags. For producers seeking both jar and bag solutions, AutoJar and AutoBag provide a seamless, complementary setup that maintains freshness and quality across packaging types.

Optional Full-Line Integration

For producers seeking a complete weed packaging automation solution, AutoBag can work with the MultiBud-24 weighing system. This pairing provides accurate weighing and bud-size distribution, enhancing the efficiency and appeal of your final packaged product.

Professional Installation and 24/7 Support

Hefestus ensures seamless setup with expert installation and training. Our 24/7 technical support keeps your operation running smoothly with fast troubleshooting, remote diagnostics, and quick-access replacement parts—minimizing downtime and maximizing efficiency.

Built for Speed, Designed for Quality

Invest in operational excellence with the premier cannabis flower packaging from Hefestus.

Boost Throughput Without Sacrificing Quality |

Preserve Product Integrity from Fill to Seal |

Flexible Enough to Grow With You |

Trusted by the Industry’s Best

Enhance your production line with reliable, efficient cannabis packaging tailored to preserve quality from start to finish with the AutoBag.

Connect with the Hefestus team today to learn more about our automated cannabis packaging machine and systems.

Talk to an ExpertThe AutoBag Cannabis Bag Filling Machine Technical Specifications

Bag Width:

| 110 mm / 4.3 in to 210 mm / 8.3 in |

Bag Length:

| 140 mm / 5.5 in to 300 mm / 11.8 in |

Max Speed:

| 26 bags per minute |

Power Requirements:

| 110V/50HZ, 3 Phase, 5 Amps |

Air Requirements:

| 6 kg/cm² / 85 psi, 0.14 m³/min / 4.9 ft³/min |

Electronics:

| Mitsubishi PLC, Omron PID Temperature Controller, Winview 10” display (Taiwan) |

Drive:

| SEW Motor Drive |

Pneumatics:

| Festo components; Piab vacuum generator (Sweden) |

Certifications:

| InterLock, CE/UL certified |

Contact Hefestus Today to Streamline Your Cannabis Packaging Line

CONTACTThe AutoBag: Cannabis Bag Filling Machine FAQs

The AutoBag: Cannabis Bag Filling Machine FAQs

What bag materials are compatible with the AutoBag automated cannabis packaging machine?

The AutoBag works with most heat-sealable bag materials commonly used in the cannabis industry, including Mylar, compostable film, and child-resistant options. Material thickness and seal strength should be reviewed before use.

Can I switch bag sizes easily during production?

Yes. AutoBag supports fast changeovers between bag sizes, allowing operators to package different SKUs without lengthy downtime or tool-intensive adjustments.

Does the AutoBag require a specific environmental setup or room size?

While the AutoBag is compact and designed to fit into standard production spaces, optimal performance is achieved in clean, climate-controlled environments with proper ventilation and electrical access.

How does AutoBag integrate with weighing systems?

AutoBag pairs seamlessly with Hefestus’s MultiBud-24 weighing system for automated, accurate flower distribution before bagging—helping to reduce overfill and ensure regulatory compliance.

Is the machine suitable for both small-batch and large-scale runs?

Absolutely. The AutoBag flower packaging device is scalable for both boutique brands and enterprise-level operations, with adjustable speed settings to accommodate lower-volume test batches or high-throughput production runs.

What kind of operator training is included with purchase?

Hefestus provides on-site or remote installation training, including system operation, cleaning procedures, and troubleshooting basics to ensure your team is confident from day one.