AutoJar Cannabis Flower Jar Packaging Machine

The Smarter Way to Preserve Cannabis in Jars

From Flower to Jar—Seamless, Secure, and Scalable Cannabis Flower Packaging

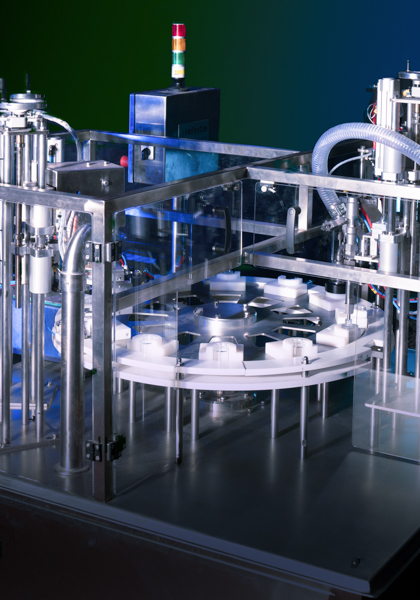

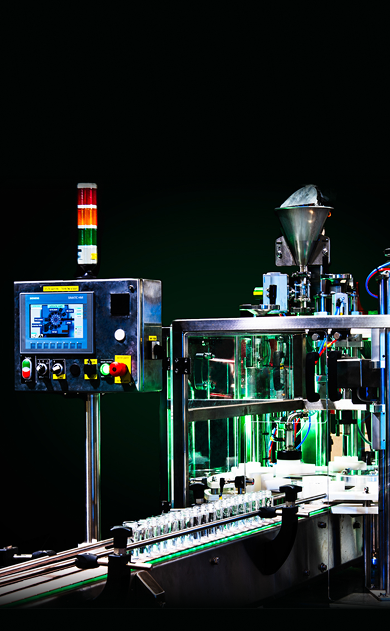

The AutoJar is a high-speed, versatile cannabis flower packaging machine with unmatched accuracy and freshness preservation.

With optional Modified Atmosphere Packaging (MAP) technology AutoJar extends shelf life, maintaining potency, aroma, and quality from packaging to purchase.

Precision, Speed, and Freshness in Every Jar

Preserve potency, extend shelf life, and enhance efficiency with smart cannabis flower packaging automation.

Precision, Speed, and Freshness in Every Jar

Preserve potency, extend shelf life, and enhance efficiency with smart cannabis flower packaging automation.

Extended Shelf Life

With MAP technology, AutoJar helps preserve cannabis aroma and potency, enhancing consumer satisfaction and reducing spoilage.

High-Speed Efficiency

The AutoJar is an elite cannabis jar packaging machine that can achieve high production rates without compromising quality, helping producers meet market demand while reducing labor costs.

Customizable Production Integration

The system seamlessly integrates into existing production lines, supporting a wide variety of packaging requirements with adjustable settings for flexibility.

Minimal Waste and Consistent Quality

Accurate filling and sealing minimize product giveaway and ensure uniform quality, meeting both consumer and regulatory expectations.

Additional Packaging Options

Hefestus also offers the AutoBag, a high-speed cannabis flower packaging system designed specifically for cannabis in bags. For producers seeking both jar and bag solutions, AutoJar and AutoBag provide a seamless, complementary setup that maintains freshness and quality across packaging types.

Optional Full-Line Integration

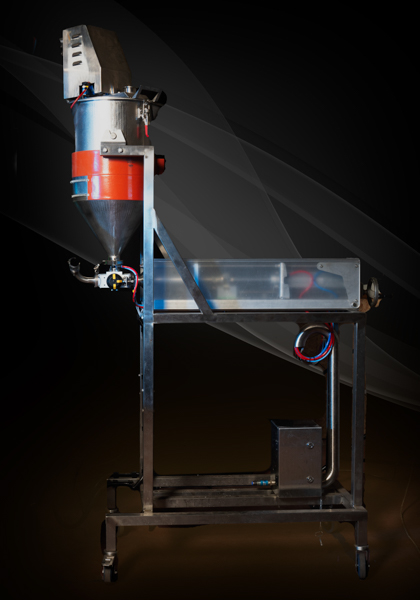

For producers seeking a complete automation solution, AutoJar can work with the MultiBud-24 weighing system. This pairing provides accurate weighing and bud-size distribution, enhancing the efficiency and appeal of your final packaged product.

Professional Installation and 24/7 Support

Hefestus ensures seamless setup of your cannabis flower packaging machine with expert installation and training. Our 24/7 technical support keeps your operation running smoothly with fast troubleshooting, remote diagnostics, and quick-access replacement parts—minimizing downtime and maximizing efficiency.

Preserve Potency. Increase Productivity.

Invest in operational excellence with the premier cannabis flower jar packaging machine from Hefestus.

Improve Product Quality and Compliance |

Cut Labor Costs, Reduce Human Errors |

Scale Production Without Sacrificing Control |

Trusted by the Industry's Best

Optimize Your Cannabis Flower Packaging to New Levels of Freshness and Quality with the AutoJar.

Connect with the Hefestus team today for more details on full-scale cannabis flower packaging automation and production.

Talk to an ExpertThe AutoJar Cannabis Flower Packaging Machine Technical Specifications

Machine Dimensions:

| L1550 mm / 61 in x W1500 mm / 59 in x H1800-2000 mm / 70.9-78.7 in |

Net Weight:

| 650 kg / 1433 lbs |

Production Speed:

| 20-75 jars per minute |

Power Requirements (USA):

| 2 Phase, V220, 25A, 2000W |

Max Container Dimensions:

| Up to 160 mm / 6.3 in diameter (single jar); customizable for various jar sizes |

Contact Hefestus Today to Streamline Your Cannabis Packaging Line

CONTACTThe AutoJar: Cannabis Flower Jar Packaging Machine FAQs

The AutoJar: Cannabis Flower Jar Packaging Machine FAQs

What types of cannabis products can be packaged with the AutoJar?

The AutoJar is optimized for whole flower packaging, but it can also accommodate small buds and trims depending on jar size and consistency. It’s not designed for ground flower or infused products.

Can the AutoJar handle child-resistant or tamper-evident caps?

Yes, the system can be customized to work with a variety of cap types, including child-resistant and tamper-evident lids, to help you meet regulatory requirements with ease.

How long does it take to set up and train staff on the AutoJar?

Most clients can complete setup and basic operator training within 1–2 days with Hefestus’s expert installation team. Additional remote support is available as needed.

Is the AutoJar compatible with sustainable or eco-friendly packaging materials?

Yes, the AutoJar works with a range of glass and biodegradable plastic jars, making it suitable for brands prioritizing environmentally conscious packaging solutions.

How does MAP technology actually preserve freshness?

Modified Atmosphere Packaging (MAP) replaces oxygen inside the jar with inert gases like nitrogen, slowing oxidation and microbial growth that can degrade cannabis quality over time.

What is the typical ROI timeframe for investing in the AutoJar?

Most operators experience a return on investment within 6–12 months, thanks to reduced labor costs, minimized product waste, and improved packaging consistency.