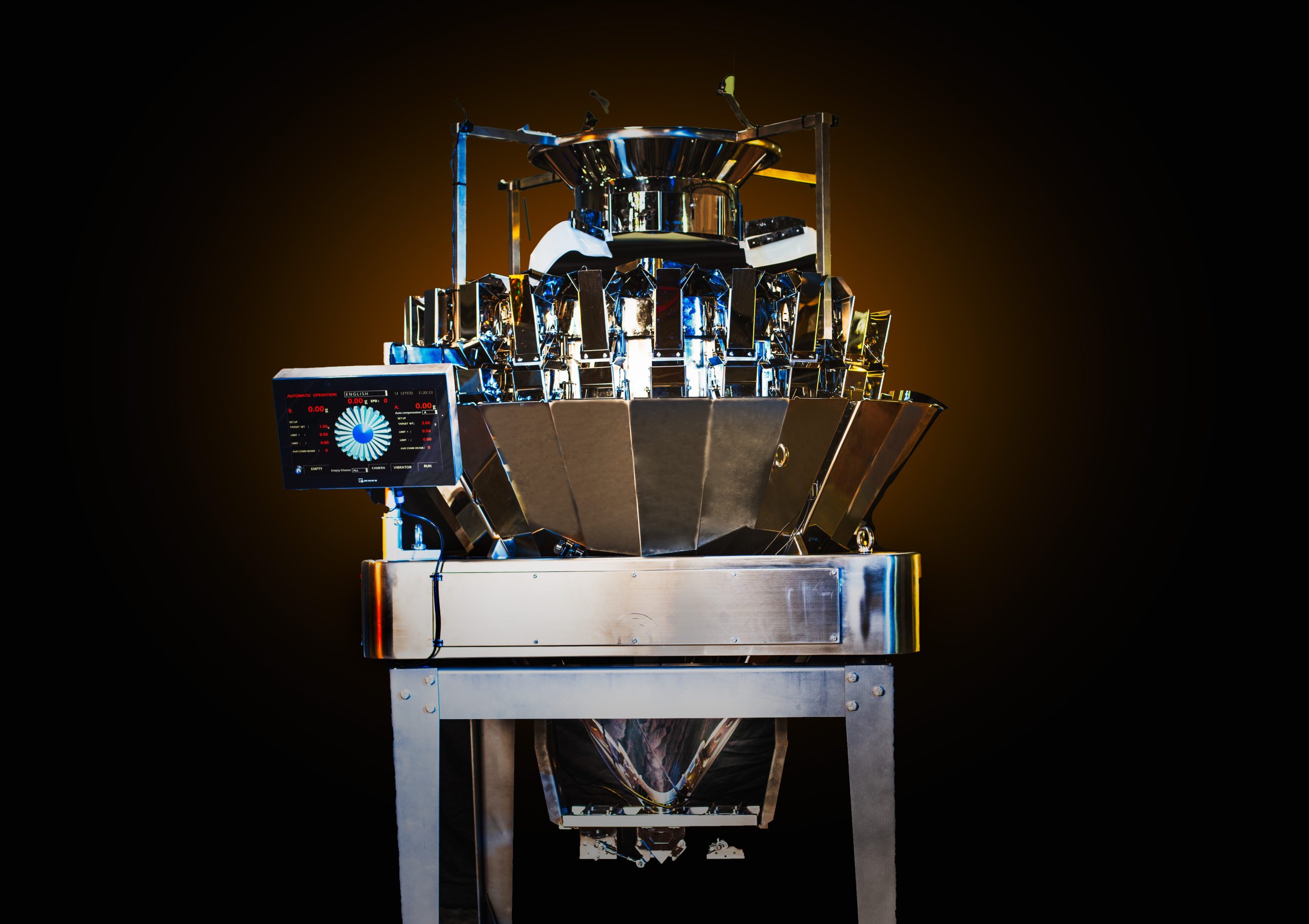

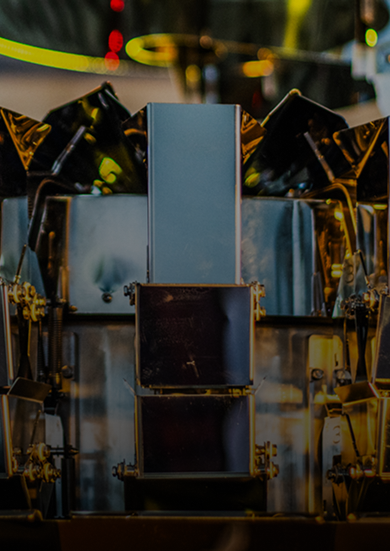

MultiBud-24 Cannabis Packaging Automation Machine

High-Precision Weighing for Optimal Cannabis Packaging

Exact Weights, Perfect Ratios, Every Time

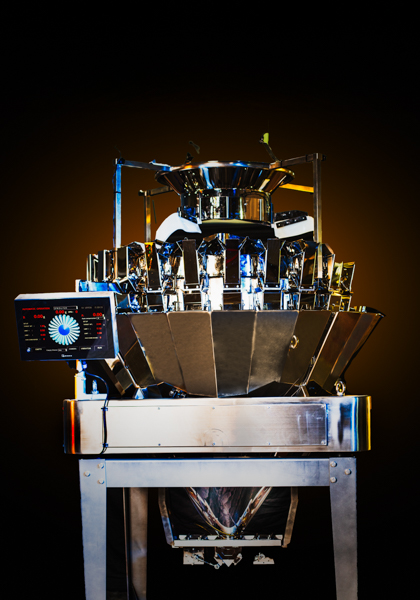

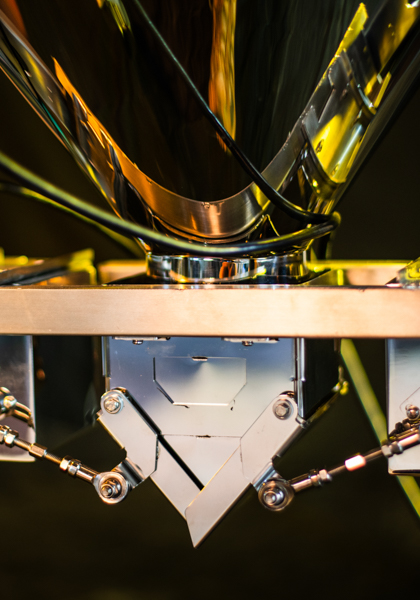

The MultiBud-24 is a high-precision multihead weigher, purpose-built for cannabis.

Designed for medium to large operations, it delivers exact weight distribution customized bud ratios, and preserves bud integrity in every jar or bag.

Sticky Bud Compatibility

Handles resinous cannabis smoothly, reducing clogs and downtime.

Unmatched Accuracy

With 24 weighing heads, the MultiBud-24 ensures precise weight distribution to avoid overfill and maximize profitability.

Automated Bud Mixing

Utilizes dual bucket elevators to maintain customizable ratios of small to large buds, ensuring a consistent and visually appealing product.

Versatile Packaging Compatibility

The MultiBud-24 Integration Platform enables seamless integration with AutoBag and AutoJar, supporting MAP technology to preserve freshness and potency.

Reliable Consistency

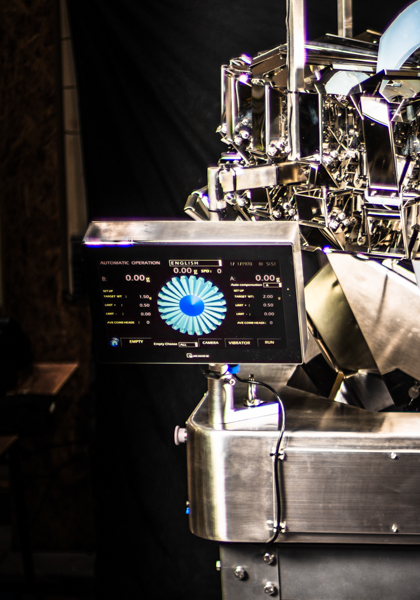

Automated calibration and tare functions meet exact weight specs, minimizing manual labor.

Optimize Every Gram with Intelligent Weighing

MultiBud-24 delivers exact weight distribution and optimized bud ratios, ensuring every jar and bag meets precise specifications.

Optimize Every Gram with Intelligent Weighing

MultiBud-24 delivers exact weight distribution and optimized bud ratios, ensuring every jar and bag meets precise specifications.

Optimal Yield and Reduced Waste

The precise weighing system minimizes overfills and underfills, helping producers save on costs by reducing waste.

Enhanced Product Appeal

Perfect bud-size distribution ensures every package has an optimal mix of large and small buds, enhancing visual appeal and consumer satisfaction.

Minimal Downtime

Built to handle the demands of high-volume production without frequent adjustments, keeping your line moving efficiently.

Streamlined Operation

Easy-to-use interface and automatic controls simplify setup and daily operation, allowing for one-operator efficiency and reduced labor costs.

Professional Installation and 24/7 Support

Hefestus ensures seamless setup with expert installation and training. Our 24/7 technical support keeps your operation running smoothly with fast troubleshooting, remote diagnostics, and quick-access replacement parts—minimizing downtime and maximizing efficiency.

Very little downtime

“We’re wasting fewer papers and less material. It’s super easy to clean and change over between strains. It’s simple to make adjustments and switch to different pre-roll sizes. There’s very little downtime compared to other machines we’ve used. Overall, it’s been a great experience.”

Read More

Matt

Pioneer Interests

“We’re wasting fewer papers and less material. It’s super easy to clean and change over between strains. It’s simple to make adjustments and switch to different pre-roll sizes. There’s very little downtime compared to other machines we’ve used. Overall, it’s been a great experience.”

Matt

Pioneer Interests

One size paper stock

“One of my favorite features of the Aura X is the scissor system. We now only need to keep one size of paper in stock: the king size. Before, we had to stock three or four different cone sizes. Now, we just set the scissors to the length we want, and the system cuts it perfectly, vacuuming up the trim automatically.”

Read More

Dan

Jacked

“One of my favorite features of the Aura X is the scissor system. We now only need to keep one size of paper in stock: the king size. Before, we had to stock three or four different cone sizes. Now, we just set the scissors to the length we want, and the system cuts it perfectly, vacuuming up the trim automatically.”

Dan

Jacked

Running hands off quickly

“Onboarding was extremely simple. Hefestus reached out, gave us an ETA of when the machine would arrive, and shortly thereafter when their team would arrive to onboard. By the end of the first day, my team was running hands off.”

Read More

Mike Lempert

Seed & Smith

“Onboarding was extremely simple. Hefestus reached out, gave us an ETA of when the machine would arrive, and shortly thereafter when their team would arrive to onboard. By the end of the first day, my team was running hands off.”

Mike Lempert

Seed & Smith

Training was straightforward

“The setup was easy. They came in, set it up the first day, and spent a couple of days training us. The training was straightforward and easy to learn.”

Read More

Matt

Pioneer Interests

“The setup was easy. They came in, set it up the first day, and spent a couple of days training us. The training was straightforward and easy to learn.”

Matt

Pioneer Interests

Setup and training flawless

“Setup and training were flawless. The machine arrived on time, the trainers stayed in close contact, and in two days we were fully dialed in.”

Read More

Dan

Jacked

“Setup and training were flawless. The machine arrived on time, the trainers stayed in close contact, and in two days we were fully dialed in.”

Dan

Jacked

Every joint comes out perfect

“The thing I love most is the consistency. Every joint comes out perfect: weight, Dutch crown, everything. And for someone like me, who is focused on quality, that’s exactly what I was looking for.”

Read More

Mike

Jacked

“The thing I love most is the consistency. Every joint comes out perfect: weight, Dutch crown, everything. And for someone like me, who is focused on quality, that’s exactly what I was looking for.”

Mike

Jacked

One cone fits all

“My team here at Seed & Smith runs everything from 1.5g joints all the way down to .35 dog walkers. The machine’s able to do all that with one cone size as the starting SKU. We’re not having to stock king size, 98s, and smaller cones. We keep one cone in stock, load the machine, and just dial where it’s going to cut. It allows us to run different SKUs much quicker than changing over parts to accommodate different sizes.”

Read More

Mike Lempert

Seed & Smith

“My team here at Seed & Smith runs everything from 1.5g joints all the way down to .35 dog walkers. The machine’s able to do all that with one cone size as the starting SKU. We’re not having to stock king size, 98s, and smaller cones. We keep one cone in stock, load the machine, and just dial where it’s going to cut. It allows us to run different SKUs much quicker than changing over parts to accommodate different sizes.”

Mike Lempert

Seed & Smith

Easily a 10x improvement

“In the early days when Seed & Smith first got rolling there wasn’t a lot of options for automation, especially in the pre-roll world. We were hand filling and using more analog methods, and on a good day with a full team we were probably seeing 1,200–1,500 units max start to finish. The major step came when we decided to move to a Hefestus machine. Now, with just a two-person crew, we’re seeing anywhere from 10,000 to 15,000 units a day start to finish; easily a 10x improvement upon what we were able to do early.”

Read More

Mike Lempert

Seed & Smith

“In the early days when Seed & Smith first got rolling there wasn’t a lot of options for automation, especially in the pre-roll world. We were hand filling and using more analog methods, and on a good day with a full team we were probably seeing 1,200–1,500 units max start to finish. The major step came when we decided to move to a Hefestus machine. Now, with just a two-person crew, we’re seeing anywhere from 10,000 to 15,000 units a day start to finish; easily a 10x improvement upon what we were able to do early.”

Mike Lempert

Seed & Smith

Every joint the same

“I was at a friend’s facility and saw the Hefestus machine in operation. I was impressed with the efficiency, the minimal labor required, and the consistency—every joint coming out the same. That got my attention. After research and comparisons, we knew we wanted to purchase a Hefestus machine and get it running in our facility to greatly increase the automation we were lacking.”

Read More

Noah

Pioneer Interests

“I was at a friend’s facility and saw the Hefestus machine in operation. I was impressed with the efficiency, the minimal labor required, and the consistency—every joint coming out the same. That got my attention. After research and comparisons, we knew we wanted to purchase a Hefestus machine and get it running in our facility to greatly increase the automation we were lacking.”

Noah

Pioneer Interests

10,000–12,000 units daily

“Since acquiring the Aura X, we’re averaging 10,000–12,000 units a day, with just one operator. That’s massive.”

Read More

Dan

Jacked

“Since acquiring the Aura X, we’re averaging 10,000–12,000 units a day, with just one operator. That’s massive.”

Dan

Jacked

Completely streamlined our process

“All in all, the Aura X has completely streamlined our process. It’s a machine I’d recommend to anyone in the industry who’s serious about efficiency and quality.”

Read More

Dan

Jacked

“All in all, the Aura X has completely streamlined our process. It’s a machine I’d recommend to anyone in the industry who’s serious about efficiency and quality.”

Dan

Jacked

No real downtime

“One of the best parts about Hefestus is their customer service. You don’t have to worry about being left hanging, they’ll call you back, and you’ll talk to a real person. If you need a part, there’s no real downtime because they include a full toolbox of spares. And if something else comes up, they’ll overnight it to you.”

Read More

Dan

Jacked

“One of the best parts about Hefestus is their customer service. You don’t have to worry about being left hanging, they’ll call you back, and you’ll talk to a real person. If you need a part, there’s no real downtime because they include a full toolbox of spares. And if something else comes up, they’ll overnight it to you.”

Dan

Jacked

Hasn’t missed a beat

“From the time we met them at BzCon to the communication while the machine was in manufacturing to delivery onboarding post operational support, there hasn’t been a single thing that missed a beat here.”

Read More

Michael Lempert

Seed & Smith

“From the time we met them at BzCon to the communication while the machine was in manufacturing to delivery onboarding post operational support, there hasn’t been a single thing that missed a beat here.”

Michael Lempert

Seed & Smith

Helped Us Meet Demand

“It’s given us a more cost-effective option to automate a product SKU that is extremely labor intensive and inefficient to produce. The Aura has helped us meet demand needs and susta...”

Read More

Jessica Ragel

Director of Operations, High Grade

“It’s given us a more cost-effective option to automate a product SKU that is extremely labor intensive and inefficient to produce. The Aura has helped us meet demand needs and susta...”

Jessica Ragel

Director of Operations, High Grade

Quality Rivals Hand-Rolled

“We struggled to find the right one because we fold our prerolls and do not twist them, I think the quality is as close to looking handmade as we can get. We are producing at least 100,000...”

Read More

Barb Hansen

Packaging & Inventory Manager, Copperstate

“We struggled to find the right one because we fold our prerolls and do not twist them, I think the quality is as close to looking handmade as we can get. We are producing at least 100,000...”

Barb Hansen

Packaging & Inventory Manager, Copperstate

This Machine is a No-Brainer

I would say to anybody that does mass production pre-rolls, this machine is a no brainer. Eliminate your labor, eliminate human error, eliminate lazy employees. And allow yourself to have a piece of equipment that functions properly for you, produces something that's super consistent, and is extremely reliable

Read More

Jay Vanderlaan

Rare Michigan Genetics

I would say to anybody that does mass production pre-rolls, this machine is a no brainer. Eliminate your labor, eliminate human error, eliminate lazy employees. And allow yourself to have a piece of equipment that functions properly for you, produces something that's super consistent, and is extremely reliable

Jay Vanderlaan

Rare Michigan Genetics

Loving Our Second Machine—Ready for a Third!

“We just acquired our second Hefestus machine and we are absolutely loving it. The service from the team at Hefestus; Shahar and team are fantastic. They’re always available and happy to assist. These machines have really helped our company bring additional SKUs to market at a reasonable entry cost. Shahar — When can we get our 3rd machine???”

Read More

Jonathan David

COO, Traditional

“We just acquired our second Hefestus machine and we are absolutely loving it. The service from the team at Hefestus; Shahar and team are fantastic. They’re always available and happy to assist. These machines have really helped our company bring additional SKUs to market at a reasonable entry cost. Shahar — When can we get our 3rd machine???”

Jonathan David

COO, Traditional

Twice the Output, Triple the Efficiency

"We can almost double the production of what we could before when we run that machine and almost triple the production of hand rolling, After previous failures, now we have product that works"

Read More

Otto Escobar

facility manager, T-Rex Distribution

"We can almost double the production of what we could before when we run that machine and almost triple the production of hand rolling, After previous failures, now we have product that works"

Otto Escobar

facility manager, T-Rex Distribution

A Great Pre-Roll Automation Partner

"I couldn’t ask for a better partner in pre-roll machines than what Hefestus has been."

Read More

Taylor Balduff

Owner at Forbidden Farms

"I couldn’t ask for a better partner in pre-roll machines than what Hefestus has been."

Taylor Balduff

Owner at Forbidden Farms

Hefestus Has Been Awesome

"We’re already thinking about buying a second machine."

Read More

Dave Nugent

Packaging Manager at Driven Grow

"We’re already thinking about buying a second machine."

Dave Nugent

Packaging Manager at Driven Grow

Love At First Sight

"From the very first introduction, it was clear to me that we would deal with Hefestus. Now our AuraX is running every day, six days a week."

Read More

Florian Lorenz

B2B Sales Director at CanAdelaar

"From the very first introduction, it was clear to me that we would deal with Hefestus. Now our AuraX is running every day, six days a week."

Florian Lorenz

B2B Sales Director at CanAdelaar

Hefestus Clients Get Results

Add-Ons for Automated Packing

Explore the future of cannabis packaging with our fully automated systems, designed for precision, efficiency,

Precision Weighing. Maximum Yield. Zero Waste

MultiBud-24 delivers unmatched accuracy, optimal bud ratios, and seamless integration with AutoBag and AutoJar. Minimize waste, maximize profitability, and preserve product integrity.

Talk to an ExpertTECHNICAL SPECIFICATIONS

Accuracy:

| 0.1 to 0.2 grams |

Weighing Range:

| 5g to 250g per outlet |

Number of Heads:

| 24 |

Weighing Volume:

| Up to 1 liter per outlet |

Construction:

| Food-grade, 304 stainless steel |

Power:

| 110V, 60Hz |

Contact Hefestus Today to Streamline Your Cannabis Packaging Line

CONTACT